Equipment Manufacturing

High-end CNC Machine Tool Development Base Project of Changchun City

1. Introduction to the Project

1.1 Project background

1.1.1 Project introduction

High-end CNC machine tools refer to CNC machine tools that integrate multiple functions such as high speed, precision, intelligence, compounding, multi-axis linkage, and network communication. The advanced form of the development of high-grade CNC machine tools is intelligent machine tools. Intelligent machine tools are the product of the integration and in-depth fusion of advanced manufacturing technology, information technology, and intelligent technology. They have functions such as self perception, self decision-making, self diagnosis, self adjustment, self adaptation, and real-time network communication. Moreover, with the continuous innovation of science and technology, intelligent machine tools, as mobile Internet intelligent terminals, will become the key processing equipment in intelligent production systems.

The project is constructed in Changchun Wukeshu Economic Development Zone. It mainly focuses on researching and developing the technology of a new generation of high-end CNC machine tools and building a production base. Centering around the machine tool industry platform, it will deeply engage in the intelligent machine tool equipment industry and build a platform for the R&D, innovation, and entrepreneurship of the intelligent machine tool industry.

1.1.2 Market prospect

(1) Status of high-end CNC machine tool industry

The core of the numerical control system consists of the controller and the driver. The controller is responsible for the real-time performance and synchronization of multi-axis linkage, while the driver mainly conducts motion interpolation and encoder closed-loop feedback adjustment.

CNC machine tools effectively address the processing problems of complex, precise, small-batch, and multi-variety parts. They are flexible and high-performance automated machine tools, representing the development direction of modern machine tool control technology and being a typical mechatronic product. There are numerous types of CNC machine tools, which can be classified in different ways. The most common CNC machine tools include CNC lathes, CNC milling machines, CNC machining centers, CNC drilling machines, CNC grinding machines, and CNC gear processing machines, etc. These machine tools are widely used in the metal-cutting field, covering everything from basic part processing to the manufacture of complex shapes, thus meeting the diverse needs of different industries.

CNC machine tools include CNC metal-cutting machine tools, CNC metal-forming machine tools, CNC special processing machine tools, machining centers, etc. The upstream of the industrial chain mainly consists of various equipment components required for CNC machine tools, including numerical control technology, numerical control systems, main components of CNC machine tools, electronic components, etc. Among them, the numerical control system encompasses servo systems, drive systems, displays, sensors, etc.; main components include castings, bearings, tracks, slides, manipulators, etc.; and electrical components include transformers, circuit breakers, transmissions, etc. The midstream is the design and production stage of CNC machine tools. As the cornerstone of modern industry, the machine tool industry is a crucial issue that cannot be bypassed in the development of the industrial economy. Due to congenital technological deficiencies, Chinese CNC machine tool enterprises have always lagged behind the mainstream foreign standards in the development of mid-to-high end machine tool projects and are in a process of catching up. The downstream application fields of CNC machine tools are extensive, covering multiple industries such as automotive manufacturing, construction machinery, rail transit, shipbuilding, aerospace, consumer electronics, petrochemicals, and the military industry.

Driven by the waves of globalization and digitalization, machine tools, as the core equipment of the manufacturing industry, are undergoing unprecedented changes and development. As the "machine tool", its accuracy, efficiency, and intelligence level will directly determine the overall competitiveness of the manufacturing industry. In recent years, with the gradual recovery of the global economy and the rise of emerging markets, the demand for machine tools in the market has increased constantly. At the same time, with the rise of technologies such as intelligent manufacturing and industrial Internet, the machine tool industry has ushered in unprecedented growth opportunities, with the market size continuously expanding and technological innovations emerging in an endless stream. In 2023, the global machine tool sales revenue was approximately $52.717 billion, a slight decrease compared to 2022. In the future, facing fierce market competition and rapidly changing market demands, machine tool enterprises will continuously innovate technologies, optimize product structures, and improve service quality, leading the machine tool industry to move towards high-end, intelligent, and green directions, and promoting the growth and development of the industry. It is expected that by 2030, the annual global sales revenue of machine tools will exceed $30 billion.

(2) Prospect analysis of high-end CNC machine tool market

In recent years, domestic brands of CNC machine tools in China have risen. With huge market demand, a large number of international-brand CNC machine tool enterprises have been attracted to enter and seize the Chinese market. After decades of development, the domestic CNC machine tool industry has continuously carried out independent research and development and absorbed foreign experience. A number of new mid-and-high end machine tool manufacturers have emerged. These manufacturers possess core design technologies and manufacturing processes, can provide high-performance, high-quality, highly customized products for their focused application fields and product types, have a wide market influence and high brand value, and are developing rapidly and dynamically.

At the same time, these emerging manufacturers, taking advantage of favorable market conditions such as the transformation of China's manufacturing industry, the increasing demand for mid-to-high end CNC machine tools, and the huge space for import substitution, while striving to develop their product and technology levels, have enhanced their financial strength through means such as public financing, achieved remarkable development, rapidly increased their market share, and promoted the development of the domestic CNC machine tool industry.

With the accelerated transformation of China's manufacturing industry, emerging industries such as precision molds, new energy, aerospace, rail transit, 3D printing, and medical devices have risen rapidly. Their manufacturing processes are highly dependent on intelligent manufacturing equipment such as CNC machine tools, which has strongly promoted the development of high-speed, high-precision, high-efficiency, high-stability, intelligent, multi-axis, and compound metal-cutting CNC machine tools suitable for various emerging fields, and greatly driven the growth of the industrial scale.

In this process, domestic CNC machine tool enterprises have not only achieved technological breakthroughs but also continuously innovated in services and solutions to meet the personalized needs of customers in different industries. Through close cooperation with downstream industries, domestic CNC machine tool manufacturers can keep abreast of market trends in a timely manner, respond quickly to market changes, and provide more precise products and services.

Looking to the future, with the continuous progress of technology and the further expansion of the market, domestic CNC machine tools are expected to achieve breakthroughs in more high-end application fields and form a more powerful competition with international brands. At the same time, domestic CNC machine tool enterprises should continue to increase R&D investment, enhance independent innovation capabilities, and strengthen brand building to achieve sustainable development. The prospects are very promising.

1.1.3 Advantageous conditions of project construction

(1) Policy advantage

"Made in China 2025" lists "high-end CNC machine tools" as one of the key development fields of the manufacturing industry in the next decade, and clarifies the future development goals of high-end CNC machine tools, stating that "by 2025, the domestic market share of high-end CNC machine tools and machine-building machines will exceed 80%".

The "14th Five-year Plan for the Development of Intelligent Manufacturing" proposes to research and develop intelligent vertical/horizontal five-axis machining centers, turning-milling compound machining centers, high-precision CNC grinding machines and other machine tools. By 2025, digitalization will be basically popularized among manufacturing enterprises above designated size, and key enterprises in key industries will initially achieve intelligent transformation. By 2035, digitalization will be fully popularized among manufacturing enterprises above designated size, and key enterprises will basically achieve intelligent transformation.

(2) Advantages of investment promotion and capital introduction

To strengthen the function of investment services, the Yushu Municipal Party Committee and the Municipal Government have successively established the Soft Environment Construction Leading Group, the Investment Promotion and Capital Introduction Work Leading Group, the Project Construction Leading Group at the municipal level, as well as the Cooperation and Exchange Center, the Project Center, etc. These organizations lead the city's work of attracting investment, launching projects, and establishing enterprises from a high-level perspective. The city-level leaders are assigned to oversee projects and maintain contact with key enterprises. The heads of relevant departments serve as "project secretaries" to provide follow-up services for settled enterprises. The municipal government has set up the Government Service Center, taking the lead in launching the "one door and one network" government service model. This has realized a service system where the public's affairs can be handled through "one window", and enterprises' affairs can be handled through "one stop" and "one network". Yushu has always adhered to attracting investment with integrity, retaining businesses with a favorable environment, and integrating with businesses through sincere sentiment, creating a first-class investment environment and entrepreneurial atmosphere. For consecutive years, it has been rated as one of the "Top 100 Small and Medium-sized Cities with the Most Investment Potential in China" by the China Urban Development Association.

(3) Location advantage

Yushu City is located in the central northern part of Jilin Province. The construction of highways has developed rapidly, its highways mainly include Tieli-Horqin Right Middle Banner Expressway, Heihe-Dalian Highway, Horqin Right Middle Banner-Tieli Highway, and Yushu-Taolaizhao Highway. It only takes two hours to reach the three surrounding major cities, Changchun, Jilin, and Harbin. There are also Yushu-Taolaizhao Railway and Yushu-Shulan Railway. For water transportation, there is the Wukeshu Wharf. Yushu is within an hour's drive from both Harbin Taiping International Airport and Changchun Longjia International Airport. Meanwhile, Yushu has opened short-distance transportation routes for civil aviation, thus forming a three-dimensional transportation network integrating railways, expressways, air transportation, and ordinary highways.

1.2 Contents and scale of project construction

The project covers an area of about 200mu, and its plan includes four main functional areas, namely the high-end CNC machine tool R&D base, the high-end CNC machine tool innovation base, the high-end CNC machine tool entrepreneurship base, and the functional leisure hall, as well as greening. New office centers, R&D centers, production workshops, and warehousing projects will be built, and relevant auxiliary facilities such as water supply and drainage projects, fire-fighting and environmental protection projects, roads, fences, and greening will be constructed in a supporting manner.

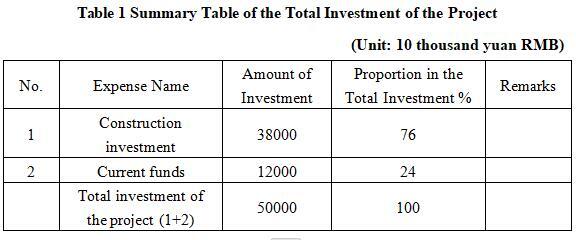

1.3 Total investment of the project and capital raising

The total investment of the project is 500 million yuan, including the construction investment of 380 million yuan.

1.4 Financial analysis and social evaluation

1.4.1 Main financial indexes

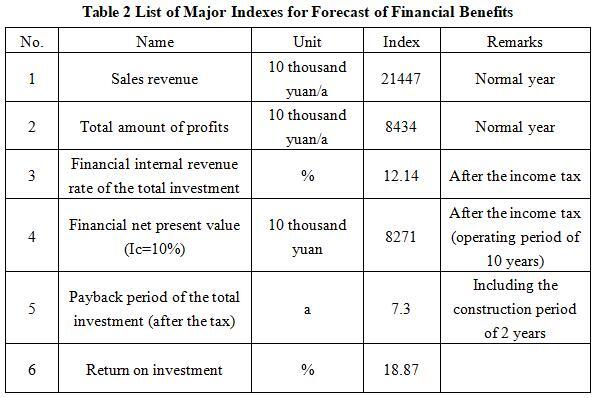

After the project reaches the production capacity, its annual sales income will be 214.47 million yuan, its profit will be 84.34 million yuan, its investment payback period will be 7.3 years (after the tax, including the construction period of 2 years), and its return on investment will be 18.87%.

Note: “10 thousand yuan” in the table is in RMB.

1.4.2 Social evaluation

The construction of the project has played a crucial role in promoting industrial upgrading and technological innovation. Meanwhile, the project has also demonstrated a positive impact on local economic development and the creation of job opportunities. According to analysis and forecasts, with the continuous maturation of technology and further market expansion, this project is expected to become a leading enterprise in the industry, injecting new vitality into the development of related industrial chains.

1.5 Cooperative way

Joint venture and cooperation.

1.6 What to be invested by the foreign party

Capital, equipment and technology.

1.7 Construction site of the project

Changchun Wukeshu Economic Development Zone

1.8 Progress of the project

The project cooperation plan has been prepared.

2 Introduction to the Partner

2.1 Basic information

Name: Changchun Wukeshu Economic Development Zone

Address: Yushu-Taolaizhao Line, Wukeshu Town, Yushu City, Changchun City (31km of Yushu-Taolaizhao Highway)

2.2 Overview

Changchun Wukeshu Economic Development Zone was established in 2003 with the approval of the provincial government as a provincial-level economic development zone. In 2022, it was "integrated and optimized" with the former Yushu City Ring Industrial Concentration Zone. Its positioning is in corn chemical industry, traditional Chinese medicine industry, green food industry, and circular economy industry. The main development pattern is "multiple parks in one zone". In recent years, with the successive introduction of well-known domestic and foreign enterprises such as COFCO Biochemical Energy (Yushu) Co., Ltd. and Jilin CP Foods Co., Ltd., the development zone has initially formed a chemical industry park, a traditional Chinese medicine industry park, a food industry park, a biomass industry park, and a livestock and poultry slaughtering industry park. The infrastructure of the park has basically reached the standard of "seven accesses and one leveling". The transportation environment is convenient and beautiful. Taolaizhao-Shulan Railway passes through the zone, and Yushu-Taolaizhao First-class Highway (also known as Shulan-Taolaizhao Highway) runs through the whole area and connects with National Highway 102 and the Beijing-Harbin Expressway. The development zone is only 1.5 hours' drive from Changchun Longjia International Airport and Harbin Taiping International Airport. The Second Songhua River flows along the border, and water transportation can go upstream to Jilin City, downstream to Harbin, and even reach border ports. The development zone has been successively rated as a "National Demonstration Base for Agricultural Products Processing Industry" by the Ministry of Agriculture and Rural Affairs, a "Provincial Demonstration Zone for Agricultural Products Processing Industry" by the Jilin Provincial Government, and a "National Top 100 Model Parks for Scientific Development" by the National Development and Reform Commission.

2.3 Contact method:

2.3.1 Contact method of project cooperator:

Contact unit: Cooperation and Exchange Center of Yushu City

Contact person: Li Lingang

Tel: +86-431-83060888

E-mail: yshzjl5021@163.com

2.3.2 Contact method of the city (prefecture) where the project is located:

Contact unit: Cooperation and Exchange Office of Changchun City

Contact person: Zhang Junjie

Tel: +86-15704317930

Fax: +86-431-82700590

E-mail: xmc82763933@163.com