Equipment Manufacturing

Low-pressure Casting Aluminium Alloy Hub Project of Changchun City

1. Introduction to the Project

1.1 Project background

1.1.1 Product introduction

Low-pressure casting is a traditional metal casting process. It manufactures wheel hubs by injecting liquid metal into a closed mold. The low-pressure casting process requires a slow injection speed of the metal and low pressure during the production process, which can ensure that the manufactured hubs have a uniform wall thickness, high density, and stable quality. The low-pressure casting process is suitable for the production of medium to large-sized and complex wheel hubs, such as automotive and motorcycle wheel hubs, and the manufacturing cost is relatively low. Low-pressure casting hubs have an exquisite and beautiful appearance, soft texture, and moderate strength.

1.1.2 Market prospect

(1) Global automobile market scale

In 2024, the global automobile sales volume reached approximately 89.01 million units, with a significant increase in the sales of new energy vehicles. Data shows that in the first eight months of 2024, the global automobile sales volume reached 58.24 million units, among which the sales volume of new energy vehicles was 9.39 million units, accounting for 16.1%. This data indicates that the global automobile market continued to grow steadily in 2024, and the market share of new energy vehicles was constantly expanding. Specifically, the proportion of pure electric vehicles was 10.4%, plug-in hybrid vehicles accounted for 5.7%, and hybrid vehicles had a market share of 5.6%.

Regionally, the automobile sales volume in the Asia/Oceania region is particularly prominent. In September, China's automobile sales volume reached 2.809 million units, ranking the first in the world, with a year-on-year growth of 1.7%. From January to September this year, China's cumulative automobile sales volume was 21.571 million units, with a year-on-year growth of 2.4%. In addition, countries such as Japan, India, and the United States also play important roles in global automobile sales.

In terms of new energy vehicles, from January to September 2024, the global sales volume of new energy vehicles reached 12.13 million units, with a year-on-year growth of 30%. To sum up, the global automobile sales volume showed a continuous growth trend in 2024, and the market share of new energy vehicles will further expand. Technological progress and policy support will be the main factors driving this trend.

(2) Prospect analysis of low-pressure casting aluminium alloy hubs

In recent years, the aluminium wheel industry has achieved remarkable development globally. With the progress of technology and the increasing requirements of consumers for vehicle performance, the aluminium wheel industry has continuously introduced new materials, new processes, and new designs to meet market demands. Especially in the context of the rapid development of new energy vehicles, the growing demand for new energy vehicle components such as hub motors has further promoted the development of the aluminium hub industry.

With the rapid development of the automotive industry, more and more vehicles are using low-pressure casting aluminium alloy hubs. Low-pressure casting aluminium alloy hubs, with their advantages of high strength, light weight, and corrosion resistance, have gradually replaced traditional steel hubs and become one of the mainstream products in the automotive industry.

The Ministry of Industry and Information Technology, the National Development and Reform Commission, and the Ministry of Science and Technology jointly issued the "Med-and-Long Term Development Plan for the Automotive Industry", in which lightweighting was identified as one of the important development directions for automobiles. With the increasing demand for the lightweight and environmental protection of truck and bus hubs to replace traditional steel rims, the research, development, and production of serialized aluminium alloy forged hubs for trucks, buses, etc. have become the key direction for the structural adjustment and optimized development of the domestic automotive parts industry. Aluminium alloy forged hubs have huge market demands both at home and abroad, and mass production of forged hubs can bring considerable economic and social benefits.

1.1.3 Technical analysis

The production process of the project is as follows:

(1) Mold Design

The production process of low-pressure casting aluminium alloy hubs begins with mold design. When designing the mold, factors such as deformation and shrinkage rate need to be considered, and then the mold material and size are determined.

(2) Alloy melting

The selected aluminium alloy materials are melted, and it is necessary to ensure that the melting temperature, holding time, and the used metals meet the standard requirements. In order to improve the quality of the castings, a small amount of rare earth elements can be added.

(3) Casting and pouring

The melted aluminium alloy liquid is poured into the pouring machine, and pressure is applied to the surface of the mold to make the aluminium liquid enter the mold. During the pouring process, attention should be paid to the safety of the staff, and it is necessary to ensure the smooth flow of the aluminium alloy fluid.

(4) Cooling

After the casting completely fills the mold, it is placed in the mold for cooling. Wait for the aluminium alloy to solidify and reach the required hardness. The length of the cooling time will affect the quality of the casting, and it needs to be judged according to the actual situation.

(5) Cleaning

After the aluminium alloy solidifies, it is taken out of the mold for surface cleaning and trimming. The excess clay and metal are cut off to make the surface smooth and beautiful.

(6) Processing

The casting aluminium alloy hubs need to be machined. Fine processing is carried out through processes such as turning and drilling to meet the required size, geometric shape, and surface roughness requirements.

(7) Testing

Finally, the quality of the aluminium alloy hubs is inspected. The dimensions, hardness, and other indicators of the hubs are measured through testing instruments to check whether the hubs meet the national standard requirements.

1.1.4 Advantageous conditions of project construction

(1) Policy advantage

Opinions of the Jilin Provincial People's Government on Implementing the "Stepping-up" Project for the Automobile Industry Cluster proposes to take the Changchun automobile cluster as a leader, promote regional coordinated development, accelerate the coordinated development and overall improvement of complete vehicles, auto parts, and the aftermarket, build a trillion-yuan and world-class advanced automobile manufacturing cluster, and build a strong automobile province and a strong manufacturing province.

Medium-and-Long Term Development Plan for the Automotive Industry proposes to cultivate internationally competitive auto parts suppliers and form a complete industrial system from auto parts to complete vehicles. By 2025, several auto parts enterprise groups will enter the top ten in the world.

(2) Industrial advantage

Jilin Province is a major automobile industry province in China. The core of its automobile industry is in Changchun, the provincial capital. FAW Group, China's first complete vehicle manufacturing enterprise, is located here. Well-known automobile manufacturers such as Volkswagen, Audi, and Toyota have joint ventures with FAW Group here. At a time when the global automotive industry is undergoing profound changes, both FAW Group and Changchun are accelerating their transformation. Building the "Changchun International Automobile City" has become a consensus between them, with the goal of building a world-class R&D, manufacturing, and aftermarket service base for automobiles and auto parts, and creating a trillion-yuan automotive industry.

(3) Location advantage

Nong'an County is located at the geometric center of the Northeast Asia region. It is an important part of the Changchun-Northeast Development and Opening Pilot Zone and an inland port of the Changchun-Jilin-Tumen National Strategy. The county is 60 kilometers away from Changchun City, the provincial capital, within the half-hour economic circle of Changchun. It is 90 kilometers away from Changchun Longjia International Airport and 700 kilometers away from Dalian Port. The southern economic growth pole is only 20 kilometers away from the multi-functional inland port (Changchun Xinglong Comprehensive Bonded Zone). The Changchun-Baicheng Railway, Changchun-Baicheng Highway, and G12 Expressway run through the county from north to south, with well-developed transportation.

(4) Talent advantage

Nong'an County has various vocational and technical schools and labor skill training bases at all levels, such as Nong'an County Vocational Education Center, Nong'an County Yude Vocational Training School, Nong'an County Lingxiang Vocational Training School, and Agricultural Mechanization School. Every year, it trains a large number of vocational and technical talents, providing a good guarantee of human resources for enterprises investing in the park.

1.2 Contents and scale of project construction

The project plans to cover an area of 21,000m2, with a construction area of 35,000m2. It is planned to build a low-pressure casting workshop, a mechanical processing and warehousing shed, a processing workshop, an employee dormitory, a comprehensive office building, etc.

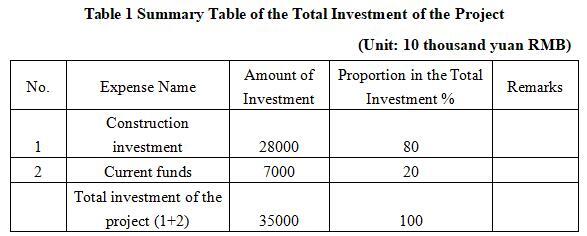

1.3 Total investment of the project and capital raising

The total investment of the project is 350 million yuan, including the construction investment of 280 million yuan.

1.4 Financial analysis and social evaluation

1.4.1 Main financial indexes

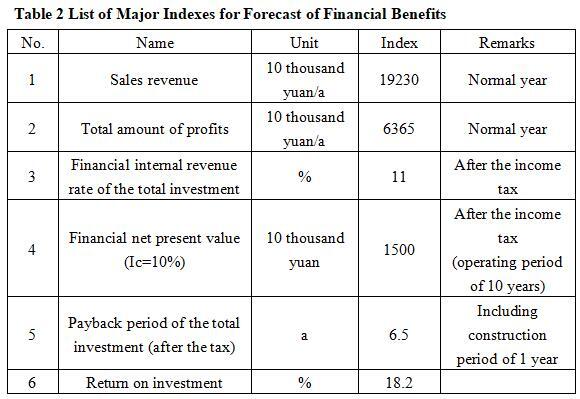

After the project reaches the production capacity, its annual sales income will be 192.3 million yuan, its profit will be 63.65 million yuan, its investment payback period will be 6.5 years (after the tax, including construction period of 1 year), and its return on investment will be 18.2%.

Note: “10 thousand yuan” in the table is in RMB.

1.4.2 Social evaluation

From the perspective of social benefits, the project products comply with national industrial policies. The implementation of this project is mainly aimed at adapting to market demands, achieving the same production scale as FAW in Changchun, expanding production scale, improving the existing working environment, increasing the degree of production automation, increasing product added value, reducing production costs, and improving economic benefits of enterprises.

1.5 Cooperative way

Sole proprietorship, joint venture or cooperation.

1.6 What to be invested by the foreign party

Capital, other ways can be discussed in person.

1.7 Construction site of the project

Nong'an County

1.8 Progress of the project

The project proposal has been prepared.

2. Introduction to the Partner

2.1 Unit basic information

Name: Economic Cooperation and Promotion Center of Nong'an County

Address: Xinghua Road, Nong'an Town, Nong'an County, Jilin Province

2.2 Unit overview

Nong'an County is located in the hinterland of the Songliao Plain in the central part of Jilin Province, with a total area of 5,400 square kilometers. It governs 22 towns and townships, 4 sub-districts, and 377 villages, with a total population of 1.2 million. It is the county with the largest cultivated area and the largest population in Jilin Province. The county seat is 60 kilometers away from Changchun City, within the half-hour economic circle of Changchun. It is 110 kilometers away from Changchun Longjia Airport and 700 kilometers away from Dalian Port. The Changchun-Baicheng Railway, G12 Expressway, C334 National Highway, and G302 National Highway run through the county from north to south. Two main roads in Changchun City, Kaixuan Road and Qingnian Road, have been extended to Nong'an County, forming a strategic opening pattern based on Changchun, connecting the surrounding areas, and integrating with Northeast China. Nong'an County took the lead in creating a national-level hygienic county in the Changchun area. It is a pilot county for expanding power and strengthening the county in the province. It has successively won honors such as one of the top 100 counties with the most investment potential in China, the most investment and business-friendly county in China, a national model county for social governance innovation, and one of the top 100 cities with the highest sense of security in China.

2.3 Contact method

Contact unit: Economic Cooperation and Promotion Center of Nong'an County

Contact person: Liu Xia

Tel: +86-431-89936018

Contact method of the city (prefecture) where the project is located:

Contact unit: Cooperation and Exchange Office of Changchun City

Contact person: Zhang Junjie

Tel: +86-15704317930

Fax: +86-431-82700590

E-mail: xmc82763933@163.com