Equipment Manufacturing

High-end Equipment Manufacturing Base Project of Jilin City

1. Introduction to the Project

1.1 Project background

1.1.1 Product introduction

The high-end equipment manufacturing industry, also known as the advanced equipment manufacturing industry, is a strategic emerging industry that is led by high and new technology, located at the high end of the value chain and the core of the industrial chain. It determines the comprehensive competitiveness of the entire industrial chain, serves as the backbone of the modern industrial system, and acts as the engine for promoting the transformation and upgrading of the industrial sector.

This project promotes cooperation in high-end machine tools, aiming to completely solve the bottleneck problem of high-end heavy-duty vertical machine tools. After the project is completed, it will be capable of an annual output of 80,000 tons of castings, 200 3D printing devices, and high-end precision machine tools.

1.1.2 Market prospect

(1) Status analysis of high-end equipment manufacturing industry

As the core area of the manufacturing industry, the high-end equipment manufacturing industry is an important reflection of a country's economic strength and scientific and technological level. In recent years, with the support of policies, technological innovation, and market demand, the high-end equipment manufacturing industry in China has made remarkable progress, but it also faces many challenges.

In recent years, the total output value of China's high-end equipment manufacturing industry has maintained a relatively high annual growth rate. For example, in the past five years, the average annual growth rate of the total output value of the high-end equipment manufacturing industry was approximately 15%. By 2023, it had exceeded the 10-trillion-yuan mark. The continuous expansion of the industry scale indicates that the high-end equipment manufacturing industry in China is becoming increasingly important in the national economy.

Both enterprises and the government have continuously increased their R&D investment in the high-end equipment manufacturing industry. In 2023, the R&D investment in the industry accounted for about 5% of the operating income, an increase of 1.5% compared to five years ago. High-level R&D investment provides a solid financial guarantee for technological innovation.

A series of key technological breakthroughs have been achieved in fields such as aerospace, rail transit, and ocean engineering. For example, the domestic large aircraft C919 successfully completed its commercial maiden flight, and the technical levels of its independently developed key components such as aero-engines and avionics systems have been significantly improved. High-speed rail technology has continued to innovate, and the Fuxing series trains have reached the world-leading level in terms of speed, safety, and comfort. The successful construction of high-end equipment such as the "Blue Whale 1" and "Blue Whale 2" offshore drilling platforms marks a major breakthrough for China in the field of ocean engineering equipment.

China has formed several high-end equipment manufacturing industrial clusters, such as the Yangtze River Delta region, the Pearl River Delta region, and the Beijing-Tianjin-Hebei region. Take the Yangtze River Delta region as an example, it has gathered numerous high-end equipment manufacturing enterprises, scientific research institutions, and universities. The industry has a complete supporting system and strong collaborative innovation capabilities. In 2023, the output value of the high-end equipment manufacturing industry in the Yangtze River Delta region accounted for about 35% of the national total, becoming an important growth pole for promoting the development of China's high-end equipment manufacturing industry.

The share of China's high-end equipment manufacturing products in the international market has been continuously expanding. For example, in the construction machinery field, products of enterprises such as Sany Heavy Industry and Zoomlion are sold globally. In 2023, the export volume increased by approximately 20% year-on-year. In the power equipment field, China's UHV power transmission technology and equipment have strong competitiveness in the international market and have been exported to many countries and regions.

Despite some key technological breakthroughs, there is still a large gap between China and developed countries in core technology areas such as high-end chips, high-end CNC machine tools, and industrial software. For example, the self-sufficiency rate of high-end chips is less than 20%, and China is highly dependent on imports, which restricts the development of the high-end equipment manufacturing industry to a certain extent.

China's high-end equipment manufacturing industry has made great progress in the past. The industry scale has been continuously expanding, the technological innovation ability has been gradually enhanced, and the international market competitiveness has also increased. However, it must be clearly recognized that the industry still faces many problems, such as core technology shortages, unbalanced development, talent shortages, insufficient enterprise innovation capabilities, and strong international competition pressure. To promote the high-quality development of China's high-end equipment manufacturing industry, the government, enterprises, and all sectors of society should work together to increase R&D investment, strengthen core technology research, optimize the industrial layout, cultivate and introduce high-end talents, improve enterprise innovation capabilities, and actively respond to international competition challenges.

(2) Status analysis of 3D printing equipment industry

3D printing is usually achieved by using digital technology-based material printers and is often used to create models in fields such as mold manufacturing and industrial design. With the development of intelligent manufacturing technology, 3D printing has gradually become an important force in cultivating and developing China's new quality productive forces, and its application scenarios are constantly expanding.

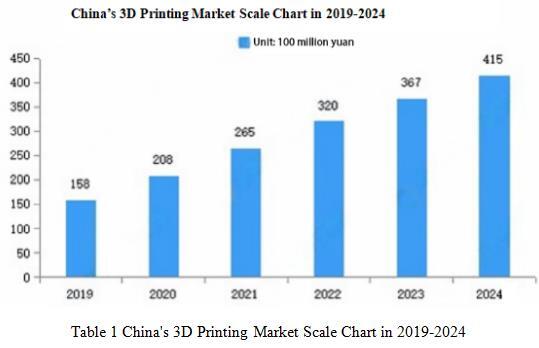

In recent years, driven by the gradual large-scale application of 3D-printed products and the release of some pent-up demand for 3D printing equipment, the market scale has continued to grow. In 2022, the market scale of 3D printing in China was approximately 32 billion yuan, with a year-on-year growth of 20.75%. In 2023, the market scale reached 36.7 billion yuan. The market scale reached 41.5 billion yuan in 2024.

From the perspective of the industrial structure, in China's 3D printing industry, the revenue from printing equipment and printing services accounts for the main part. Currently, the revenue from equipment accounts for 55%, and that from printing services accounts for 21%. Raw materials and components account for 16% and 7% respectively.

The government's support for the 3D printing industry has been continuously increasing, providing strong support for the development of the industry. The government has issued a series of policies to encourage enterprises to increase R&D investment, promote technological innovation, and industrial upgrading. In addition, the government has also taken measures such as setting up special funds and providing tax incentives to reduce the innovation costs of enterprises and stimulate market vitality. The implementation of these policies has not only promoted the rapid development of 3D printing technology but also promoted the improvement of the relevant industrial chain, laying a solid foundation for the sustainable development of the industry.

The 3D printing industry in China shows strong potential in technological innovation. With the continuous efforts of domestic scientific research institutions and enterprises, remarkable progress has been made in 3D printing technology in terms of materials, equipment, and software. For example, the research and development of new high-performance materials such as new polymer materials and metal powders provides more choices for 3D printing and promotes the transformation and upgrading of the manufacturing industry. At the same time, domestic enterprises have continuously improved the accuracy, speed, and stability of 3D printing equipment, enabling 3D printing technology to be applied in more fields.

The application scenarios of 3D printing technology in China are constantly expanding. It plays an important role in traditional fields such as aerospace, healthcare, and construction, as well as emerging fields such as education, entertainment, and cultural and creative industries. Especially in the healthcare field, 3D printing technology provides strong support for customized medical devices and surgical simulations, promoting the improvement of medical standards. At the same time, 3D printing technology is also integrated with other technologies such as artificial intelligence and the Internet of Things, promoting the intelligent development of the manufacturing industry. This integration and innovation not only enhances the value of 3D printing technology but also opens up more possibilities for the future development of the industry.

(3) Current situation of high-end precision machine tool industry

In July 2024, the output of metal-cutting machine tools in China was 54,000 units, with a year-on-year growth of 8.0% in that month. This data shows that China's metal-cutting machine tool industry showed a positive development trend in July. Overall, in July, the industrial sector maintained rapid development, the equipment manufacturing industry continued to play a stabilizing role, new quality productive forces continued to be cultivated and strengthened, the high-tech manufacturing industry grew rapidly, and the general-purpose and special-purpose equipment industries were generally stable. The growth rate of machine tool output increased significantly compared to the previous month.

In July, the total value of machine tool orders in Japan was 123.96 billion yen, with a year-on-year growth of 8.4% and a month-on-month decrease of 7.4%. Among them, external demand was 88.37 billion yen, with a year-on-year growth of 17.9% and a month-on-month decrease of 5.0%. In June's orders, orders from China were 31.7 billion yen, with a year-on-year growth of 66.0%. China's orders for imported high-end machine tools from Japan have maintained a 60% growth for two consecutive months, indicating that China still has strong demand for imported high-end machine tools.

However, China's manufacturing industry is currently under significant pressure. In July, China's manufacturing PMI was 49.4%, falling below the critical level. Against the background of a weak domestic real-estate market and weak external demand, the endogenous growth momentum of China's manufacturing industry remains insufficient, and the foundation for economic recovery still needs to be consolidated. Among them, in July, the new export order index of the manufacturing PMI fell by 2.1% to 47.4%, indicating weak external demand performance. Against the background of a trend-based decline in the overseas economy, China's exports still face downward pressure in the coming months.

On July 18, the State-owned Assets Supervision and Administration Commission issued the "Guiding Opinions on Standardizing the Procurement Management of Central Enterprises." It stipulates that for the first-set (unit) of equipment, first-batch of materials, and first-edition of software listed in the relevant catalogs of the Ministry of Industry and Information Technology and other departments, as well as the achievements in the "Recommended Catalogue of Scientific and Technological Innovation Achievements of Central Enterprises," under the consideration of enterprise economic efficiency, negotiation or direct procurement methods can be adopted. Enterprises are encouraged to reserve procurement shares and conduct trial-use first.

The Ministry of Industry and Information Technology officially issued a notice to deploy and carry out the "Industrial Machine Tool +" Industry-Enterprise Production-Demand Docking Activity to accelerate the integrated development of enterprises in the industrial machine tool industry chain. The activity will establish a sound production-demand docking channel and promote a number of cooperation projects between the supply and demand sides of industrial machine tools in areas such as paired-up tackling of key problems, application iteration, renewal and upgrading, and market expansion. It is understood that the activity will last until the end of 2027.

The State has intensively introduced a series of industrial policies to support the development of the machine tool industry. CNC machine tools have been included in the "14th Five-year Plan" outlines of 12 provinces and cities. The "Made in China 2025" strategic plan clearly states that "by 2025, China's numerical control rate of key processes will increase from the current 33% to 64%." The "Action Plan for Promoting Large-Scale Equipment Upgrades and Consumer Goods Trade-in" proposes that "by 2027, the penetration rate of digital R&D and design tools and the numerical control rate of key processes in industrial enterprises above a designated size will exceed 90% and 75% respectively." Strong policy support encourages and fosters the further development of enterprises in the CNC machine tool manufacturing field, striving to promote China's machine tool industry to reach the international industry level and providing a favorable policy environment for the industry's operation and development.

Domestic leading machine tool enterprises have continued to focus on the research, development, and promotion of high-end five-axis machine tools. Currently, they have gradually achieved breakthroughs and are on the fast-track of development. Five-axis machine tools have high-precision, high-efficiency, and high-complexity processing capabilities and can meet the needs of high-end manufacturing industries such as aerospace, automotive, and mold manufacturing. With the continuous breakthroughs of domestic enterprises in five-axis machine tool technology, China's high-end manufacturing industry's dependence on imported machine tools will gradually decrease.

The machine tool industry is developing towards intelligence. Intelligent machine tools have the characteristics of high automation, stable accuracy, and high production efficiency. By integrating sensors, control systems, and communication technologies, intelligent machine tools can achieve functions such as self-diagnosis, adaptive processing, and remote monitoring, improving production efficiency and product quality and reducing production costs and labor input.

Under the background of increasing environmental awareness, the machine tool industry is also actively promoting green manufacturing. Green manufacturing includes aspects such as energy-saving design, application of environmentally friendly materials, and waste recycling. By adopting advanced energy-saving technologies and environmentally friendly materials, machine tools can reduce energy consumption and environmental pollution during the production process, meeting the requirements of sustainable development.

Although China's machine tool industry has achieved certain development in recent years, there is still a certain technological gap compared with the international advanced level. In the field of high-end machine tools, China still relies on imports. For example, in the fields of five-axis linkage CNC machine tools and high-precision machining centers, China's technological level and product quality still need to be improved.

There are gaps in technology and quality between China and the international advanced level in the core components of machine tools, such as numerical control systems, spindles, and lead screws. Some high-end core components still rely on imports. This not only increases the production costs of Chinese machine tool enterprises but also restricts the independent development of China's machine tool industry.

The global machine tool market is highly competitive. Chinese machine tool enterprises not only face competition from domestic peers but also need to compete with well-known international machine tool enterprises. Well-known international machine tool enterprises have advantages in technology, brand, and service. Chinese machine tool enterprises need to continuously enhance their own strength to gain a foothold in the market competition.

With the transformation and upgrading of China's manufacturing industry, the demand for high-end machine tools will continue to increase. In the future, China's machine tool industry will increase R&D investment in high-end machine tools, improve product quality and technological level, and gradually achieve the domestic substitution of high-end machine tools.

Intelligence is an inevitable trend in the future development of the machine tool industry. Chinese machine tool enterprises will strengthen the research, development, and application of intelligent technologies, launch more intelligent machine tool products, improve production efficiency and product quality, and meet market demands.

As the "basic tool for machine manufacturing in the industry," machine tools play a crucial role in the national industrial system. At present, China's machine tool industry shows a positive development trend in terms of output, policy support, and technological innovation, but it also faces challenges such as technological gaps, dependence on imported core components, and fierce market competition. In the future, China's machine tool industry will develop towards high-end, intelligent, green manufacturing, and industrial integration, continuously enhancing its own strength and making greater contributions to the transformation and upgrading of China's manufacturing industry and the country's economic development.

1.1.3 Technical analysis

The technology used is not limited to the current ones. If the settled enterprises have innovative technologies, the technologies of the settled enterprises will be adopted. This technical analysis is only for reference.

The project will introduce the advanced technical means of teams led by professors such as Zhao Hongwei, Liu Zhifeng, Yang Zhaojun, and Zhou Guangwen.

1.1.4 Advantageous conditions of project construction

(1) Policy advantage

The "14th Five-year Plan for the Development of Intelligent Manufacturing" points out that efforts should be made to develop intelligent manufacturing equipment. In view of the weaknesses in the links of perception, control, decision-making, and execution, strengthen joint innovation among industry, academia, and research institutions, and break through a number of "bottleneck" basic components and devices. Promote the in-depth integration of advanced processes, information technology, and manufacturing equipment. Through the construction of intelligent workshops/factories, drive the accelerated development and iterative upgrading of general-purpose and special-purpose intelligent manufacturing equipment. Promote the innovative application of new technologies such as digital twins and artificial intelligence, and develop a number of internationally advanced new-type intelligent manufacturing equipment.

The "Industrial Energy Efficiency Improvement Action Plan" mentions promoting the energy-saving and efficiency-improving transformation and upgrading of key industries. Accelerate the industrial application of advanced near-net-shape forming process technologies such as integrated die-casting, mold-free casting, ultra-high-strength steel hot forming, precision cold forging, dissimilar-material welding, lightweight high-strength alloy lightweighting, and laser heat treatment.

The "Implementation Plan for Promoting Equipment Upgrades in the Industrial Field" proposes, for industries where the overall level of production equipment such as industrial machine tools, agricultural machinery, construction machinery, and electric bicycles is at a medium-low level, to accelerate the elimination of backward and inefficient equipment and old equipment that has exceeded its service life, and focus on promoting the replacement of machine tools that have been in service for more than 10 years in the industrial machine tool industry.

The "Investment Promotion Policies of Jilin City" clearly state that projects invested by Jilin City's industrial investment guidance fund should comply with national and relevant industrial policies and development plans, and mainly be directed towards industries related to Jilin City's "6411" industrial plan, such as tourism, medical and health, aviation, information technology, new materials, advanced equipment manufacturing, biotechnology, energy conservation and environmental protection, new energy, cultural and creative industries, modern agriculture, and modern service industries, as well as other fields strongly supported by the municipal government. In addition to the investment method of participating in the establishment of sub-funds, the guidance fund can also adopt methods such as follow-up investment and direct investment. For newly introduced eligible investment promotion projects, in accordance with current national and provincial tax policies, they can enjoy tax exemptions and reductions. For projects that make significant contributions to Jilin City, in accordance with the spirit of the "Notice of the State Council on Matters Related to Preferential Policies such as Taxation" (GF [2015] No. 25), relevant departments will assist enterprises in applying for tax reductions and exemptions in accordance with laws and regulations. A special industrial enterprise development fund will be set up to encourage the introduction of major projects in traditional industries such as chemicals, automobiles, metallurgy, and agricultural product processing within the "6411" industrial system, which comply with national industrial policies, have strong industrial support, and have obvious driving effects. At the same time, the introduction of emerging industries such as medical and health, new materials, advanced equipment manufacturing, and electronic information will be encouraged. Key inclinations will be given in the allocation of production factors, and such projects will be preferentially recommended for support from relevant national and provincial special funds.

(2) Resource advantage

Jilin City has great development potential in resources such as hydropower, wind energy, solar energy, biomass energy, and oil shale. The water system within Jilin City is well-developed, and hydropower resources are abundant. It consists of some river sections and tributaries of the Songhua River, Lalin River, and Mudanjiang River systems. The annual utilizable water resource volume is 17 billion cubic meters. The per capita water resource volume is 1.8 times of the national average and 5.4 times of northern cities. It can not only fully develop hydropower projects but also has the conditions for building large-scale pumped-storage power plants. The equivalent full-load grid-connected hours of wind power in various regions mainly range from 2000 to 3300 hours. Jilin City is located in the central part of Jilin Province. The total solar radiation is between 4800-5000 megajoules per square meter, and the radiation amount in all regions of the city is basically the same. The annual sunshine distribution is basically consistent with the solar radiation distribution, with an average annual power generation hours of 1320 hours.

The total installed power capacity of the city is 10 million kilowatts. During the 14th Five-year Plan period, an additional 3.279 million kilowatts of installed capacity will be added, with an average annual growth rate of 8.3%. Among them, coal-fired power generation accounts for 3.07 million kilowatts, accounting for 30.7%; gas-fired power generation is 0.86 million kilowatts, accounting for 8.6%; wind power is 1.54 million kilowatts, accounting for 15.4%; photovoltaic power generation is 0.7 million kilowatts, accounting for 7%; hydropower is 3.5 million kilowatts (3.2 million kilowatts of conventional hydropower and 0.3 million kilowatts of pumped-storage hydropower), accounting for 35%; biomass power generation is 0.27 million kilowatts, accounting for 2.7%; waste power generation is 0.058 million kilowatts, accounting for 0.6%. The installed capacity of new energy and renewable energy accounts for 60.7% of the total installed capacity. It is expected that the power generation in 2025 will reach 20.63 billion kilowatt-hours, and the total substation capacity of urban and rural power grids will reach 4891.1 megavolt-amperes.

Jilin City has a large stock of developable land resources. The newly-added land and reserved land can meet the needs of newly launched projects. The land price is at a low level among the 41 cities in Northeast China.

(3) Industrial advantage

Jilin City is an old industrial base in Northeast China. It is hailed as the cradle of China's chemical industry, the first metallurgical industrial base, and the mother of hydropower in New China. During the First Five-year Plan period, 7.5 out of the 156 key national projects were located in Jilin City (the construction and commissioning of Jilin Dye Stuff Factory, Jilin Fertilizer Factory, Jilin Calcium Carbide Factory, Jilin Carbon Factory, Jilin Ferroalloy Factory, Jilin Thermal Power Plant, and New China Sugar Refinery Factory, as well as the renovation and expansion of Fengman Power Plant). It contributed the first bag of fertilizer, the first barrel of dye, and the first furnace of calcium carbide to the country. In the chemical industry, Jilin City has nearly a thousand chemical industrial-scale installations above a certain size. The production capacity of 11 installations, such as methyl isobutyl ketone and methyl methacrylate, ranks among the top three in China. The 1.2 million ton ethylene transformation and upgrading project of Jilin Chemical Industry, with a total investment of 33.9 billion yuan, is being advanced in an orderly manner. This is the largest single investment industrial project in our province since the founding of New China, and it is also the first chemical project of CNPC Group that uses all green electricity. After its completion and commissioning, PetroChina Jilin Chemical Company will march towards becoming a world-class enterprise. In the carbon fiber industry, Jilin City has the only "National High-tech Industrialization Base for Carbon Fiber" approved by the Ministry of Science and Technology. It has formed the most complete domestic carbon fiber industrial chain of "acrylonitrile - acrylonitrile-based elementary fiber - carbon fiber - downstream products". The elementary fiber production capacity ranks first in the world, and the carbon fiber production capacity ranks first in China and second in the world. In the metallurgical industry, Jilin City has the largest metallurgical base in the province and two national-level metallurgical technology centers. Jianlong Group has become the largest iron and steel production enterprise in the province.

Facing future development, Jilin High-tech Zone has implemented the "435" development strategy (strengthening the four leading industries of "automobiles and auto parts, electronic information, medical and health, and equipment manufacturing"; cultivating three industrial clusters of "large-scale equipment, large-scale medicine, and big data"; and achieving an industrial scale of a "50 billion yuan development zone"). It aims to foster new quality productivity, lead new-type industrialization, build a benchmark for innovative vitality, economic vitality, ecological vitality, and social vitality, create a high ground for the development of strategic emerging industries and an engine for high quality development, and with high spirits, build a new Jilin High-tech Zone in the new era that combines both form and spirit.

(4) Talent advantage

Jilin City is home to several universities and colleges, such as Northeast Electric Power University, Jilin Institute of Chemical Technology, Beihua University, Jilin Agricultural Science and Technology University, Jilin Medical University, Jilin Vocational College of Electronic Information, Jilin Vocational College of Industry and Technology, Jilin Railway Vocational and Technical College, and Jilin General Aviation Vocational and Technical College. These institutions offer automotive-related majors, providing a continuous stream of talent support for auto parts manufacturing enterprises.

In addition, Jilin City has a large number of high-quality industrial workers. After being trained by enterprises and public welfare institutions, more than 10,000 skilled workers are dispatched to the society every year, and over 20,000 person-times of various types of personnel are trained for the society. The city has obvious advantages in labor resources. The proportion of skilled workers is relatively high among the urban agglomerations in Northeast China. The labor force is in a dividend period, with relatively low labor costs. There is a large team of high-quality industrial workers, which can meet the needs of various enterprises.

(5) Location and transportation advantage

Jilin City is located in the east central part of Jilin Province. It adjoins Yanbian Korean Autonomous Prefecture to the east, faces Changchun City and Siping City to the west, borders Harbin City in Heilongjiang Province to the north, and neighbors Baishan City, Tonghua City, and Liaoyuan City to the south.

Situated at the geographical center of Northeast Asia, Jilin City has various transportation modes, including railway, highway, waterway, and aviation. Jilin Longjia International Airport and Jilin Airport, along with major transportation arteries such as the Changchun-Hunchun Expressway, Shenyang-Harbin Expressway, Changchun-Hunchun Inter-city High-speed Railway, and the Shenyang-Harbin Double-track Railway, forming a well-connected, fast, and convenient three-dimensional transportation network in Jilin City.

1.2 Contents and scale of project construction

1.2.1 Construction scale

The project covers an area of 150,000㎡, which will realize annual production of 80,000t castings, 200 3D printing devices and high-end precision machine tools after it is completed.

1.2.2 Construction contents

The project covers total construction area of 160,000㎡, which will mainly construct an innovative technology research and development center, a test and inspection center, production workshops, a display center, dormitories, a comprehensive service center, and other supporting facilities, and purchase production lines for castings, 3D printing equipment, and high-end precision machine tools.

1.3 Total investment of the project and capital raising

1.3.1 Total investment of the project

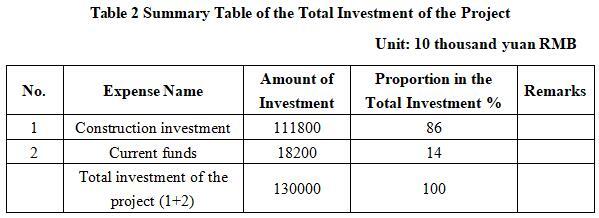

The total investment of the project is 1.3 billion yuan, including the construction investment 1.118 billion yuan, and current funds 182 million yuan.

1.3.2 Capital raising

Self-raised by the enterprise.

1.4 Financial analysis and social evaluation

1.4.1 Main financial indexes

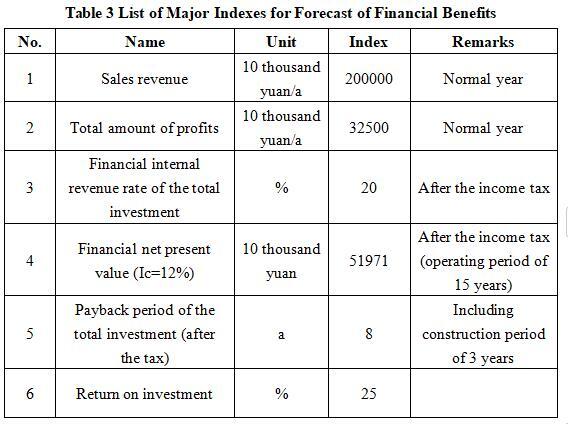

After the project reaches the production capacity, its annual sales income will be 2 billion yuan, its profit will be 325 million yuan, its investment payback period will be 8 years (after the tax, including construction period of 3 years), and its return on investment will be 25%.

Note: “10 thousand yuan” in the table is in RMB.

1.4.2 Social evaluation

This project will address bottleneck issues such as those related to high-end heavy-duty vertical machine tools. It will drive the development of the upstream and downstream industrial chains, covering various aspects including raw material supply, component manufacturing, and system integration. This will contribute to the formation of a more complete industrial chain and an improvement in the overall industrial level. Through the construction of the high-end equipment manufacturing project, the transformation and application of scientific and technological achievements can be promoted, turning these achievements into real productive forces, thereby propelling the economic and social development of Jilin City. It will enhance Jilin City's competitiveness in the high-end equipment manufacturing field, enabling the city to gain a more favorable position in regional competition.

1.5 Cooperative way

Joint venture, other methods can be discussed in person.

1.6 What to be invested by the foreign party

Capital, other methods can be discussed in person.

1.7 Construction site of the project

Jilin Changyi Economic Development Zone.

1.8 Progress of the project

Foreign investment attraction.

2. Introduction to the Partner

Name: Bureau of Commerce, Changyi District, Jilin City

Address: Changyi District, Jilin City

2.2 Overview

Changyi is an urban area with obvious location advantages. It is located in the northwest of Jilin urban area, adjacent to Chuanying District on the west side. The south and east sides are bounded by the Songhua River, separated from Fengman District and Longtan District. The north side is connected to Jiutai District of Changchun City. The urban area is surrounded by the river on three sides and backed by mountains on one side. As a window area of Jilin City, Changyi has distinct location advantages and a well-connected transportation network. The railway station, passenger terminal, and inter-city railway transfer center are all located within the urban area. At present, Ertaizi Airport is promoting its resumption of flights and will become an air cargo base that can be covered within a 2-hour flight range. It has railway logistics resources such as the Gudianzi Station secondary logistics base, which is conducive to Jilin City expanding its opening up and promoting development by leveraging the China-Mongolia-Russia logistics corridor and the China-Europe freight trains. The Hunchun-Ulanhot Expressway has a service area and entrance/exit in Huapichang Town, further improving the regional transportation system. The effective connection of transportation modes such as highways, railways, and aviation has gradually formed an efficient and reliable multimodal transport network that is smooth internally and connected externally, providing support for Jilin City to further connect to the "Changchun - Hunchun - Europe" air-rail corridor. Furthermore, in the north-south axis, Changyi District is a hub for the connected development of Jilin High-tech North Zone and Economic Development Zone, two national-level development zones. In the east-west axis, taking advantage of the construction opportunity of the Changchun-Jilin Joint Area in the National Urban-Rural Integration Development Pilot Zone, Changyi has become the main front for the counter-progressive development of Changchun and Jilin cities. It has important strategic significance for Jilin City to build a new development pattern and achieve high-quality development.

Changyi has gathered abundant and high-quality scientific and technological innovation and talent resources. Jilin Agricultural Science and Technology University has a campus in Zuojia Town, housing two colleges, namely the College of Animal Science and Technology and the College of Traditional Chinese Medicine. It offers 7 undergraduate majors and 4 junior college majors. Currently, there are 27 professors, 68 associate professors, 97 doctors (including those studying), and the proportion of teachers with a master's degree or above is 98%. There are 125 "double-qualified" teachers. It undertakes 8 national-level projects and 42 provincial and ministerial projects. PetroChina Jilin Chemical Engineering Co., Ltd. has been selected as one of the top 100 comprehensive strength units in the national survey and design industry for many times. More than 200 technological achievements have won provincial, ministerial, and national awards, and there are 6 technical experts enjoying special allowances from the State Council. The think tank effect of large-scale universities and research institutions is being released at an accelerating pace, providing solid intellectual support for the high-quality development of Changyi District.

2.3 Contact method

Contact method of the project unit:

Contact unit: Bureau of Commerce, Changyi District, Jilin City

Postal code: 132000

Contact person: Bi Changxin

+86-13244207333

E-mail: 249145141@qq.com

Contact method of the city (prefecture) where the project is located:

Contact unit: Investment Promotion Service Center of Bureau of Commerce of Jilin City

Contact person: Jiang Yuxiu

Tel: +86-432-62049694

+86-15804325460

E-mail:jlstzcjfwzx@163.com