Equipment Manufacturing

Annual Production of 400,000 Sets of Agricultural Vehicle and Passenger Car Seats Project of Siping City

1. Introduction to the Project

1.1 Project background

1.1.1 Product introduction

As one of the automotive components with the highest value, passenger car seats not only meet functional requirements but also play a crucial role as key interior components for consumers' experience. Currently, seats are evolving from single-functional products to core systems for consumption upgrading. This project aims to build a smart factory. By introducing cutting-edge technologies such as automation and relying on the existing advantageous resources of Jilin Bainuowei Auto Parts Co., Ltd., it will cooperate with strategic investors to produce key components applicable to the fields of household cars and agricultural vehicles, including automotive seats, seat motors, transmissions, electric vehicle drive systems, and electric controls.

1.1.2 Market prospect

(1) Current situation of agricultural vehicle and passenger car seat markets

Current situation of the agricultural vehicle market:

As an important part of agricultural mechanization, the agricultural vehicle market has a huge scale and is continuously growing. In recent years, with the acceleration of the global agricultural modernization process and the continuous attention and investment of the state in the agricultural field, the agricultural vehicle market has shown a vigorous development trend. The expansion of the market scale is mainly attributed to the continuous improvement of agricultural mechanization levels and the continuous increase in agricultural production efficiency. In modern agriculture, agricultural vehicles, as key production tools, are applied in multiple links such as farming, harvesting, and transportation, and play a vital role in improving agricultural production efficiency and reducing labor costs.

The current situation of the agricultural vehicle market is characterized by a continuously expanding market scale, fierce competition, diverse product types, and strong market heterogeneity. With the expansion of agricultural production scale and technological progress, the market scale of agricultural vehicles has been increasing year by year, with sales reaching hundreds of billions of yuan. The market competition is fierce, and various manufacturers are vying for market share through technological innovation and product optimization. Product types are diverse, including traditional mechanical vehicles such as tractors and combine harvesters, as well as emerging intelligent agricultural machinery equipment.

In terms of growth trends, the agricultural vehicle market is expected to maintain a steady growth trend in the future. With the continuous growth of the global population and the continuous increase in food demand, there is an urgent need to improve agricultural productivity. As a key means to improve agricultural production efficiency, the market demand for agricultural vehicles will continue to expand. The state's support for agricultural mechanization is constantly increasing. Through the introduction of a series of policies such as purchase subsidies and technical training, the level of agricultural mechanization will be further enhanced. Technological innovation also brings new development opportunities to the agricultural vehicle market. With the continuous application of intelligent and automated technologies, the performance and functions of agricultural vehicles will be further improved to meet the more efficient and convenient needs of agricultural production.

The market scale of agricultural vehicles is constantly expanding, and the predicted sales will increase year by year. The agricultural vehicle market is expected to maintain a growth trend, and the development of intelligent and green technologies will further promote market expansion.

Current situation of the passenger car seat market:

Automotive seat products can be mainly divided into seat frames, seat motors, recliners, slides, foam sponges, and seat covers according to component structures. Different vehicle models have different configuration requirements, and seats need to be customized and developed for different vehicle models. For example, sedans and SUVs are equipped with a driver-side seat frame, a passenger-side seat frame, a rear-seat frame, and seat slides per vehicle; MPVs or crossover passenger vehicles are equipped with a driver-side seat frame, a passenger-side seat frame, a rear-seat frame, a middle-seat frame, and seat slides per vehicle.

Globally, the automotive seat market is mainly dominated by foreign-owned brands such as Lear, Adient, Toyota Boshoku, Faurecia, and Magna. The combined market share of these five brands is as high as 78%. In the Chinese market, foreign-owned brands such as Lear and Adient also occupy a relatively high share relying on their technological advantages, OEM customer resources, and first-mover advantages. In the Chinese automotive seat industry, domestic-owned brands such as HASCO are gradually emerging, and their market shares are constantly increasing. Although the current market share of domestic seat manufacturers is still relatively low, with the rapid development of the Chinese automotive industry and the continuous improvement of consumption levels, the trend of domestic substitution will become more obvious.

The future development trends of the automotive seat industry market will show characteristics such as lightweight, intelligent, equal emphasis on safety and comfort, personalization and customization, as well as environmental protection and sustainable development. At the same time, the market scale will continue to expand, technological innovation will drive the development of the industry, the integration and collaborative development of the industrial chain will become an important trend, and international competition and cooperation will also be closer.

(2) Market prospects of agricultural vehicle and passenger car seats

Market prospects of agricultural vehicles:

The future development prospects of the agricultural machinery market are promising. The agricultural machinery industry is in a strategic opportunity period of industrial transformation and product upgrading and is expected to maintain a good development momentum.

First, the state's attention to the "agriculture, rural areas, and farmers" work is constantly increasing. The implementation of the national food security strategy and the rural revitalization strategy has accelerated the modernization of agriculture and rural areas. The continuous implementation of a series of preferential agricultural policies has provided substantial benefits for the healthy development of the agricultural machinery industry.

Second, the agricultural machinery industry is focusing on forward-looking technological trends, key core technologies, and the innovation and breakthrough of "bottleneck" components, and is promoting upgrading from both ends of large-and small-scale agricultural machinery equipment. This will promote the popularization and application of high-horsepower high-end machinery, small-scale machinery for hilly and mountainous areas and facility horticulture, and high-end intelligent machinery, and help the industry cultivate a number of high-quality products and leading enterprises with core technologies and strong competitiveness.

Third, the implementation of the new round of agricultural machinery scrapping policy is expected to drive a market demand of hundreds of billions of yuan and accelerate the entry of agricultural machinery products into a new demand cycle. At the same time, with the technological transformation and upgrading of manufacturing equipment, the manufacturing capacity of mid-to-high-end products in the agricultural machinery industry will be steadily improved.

Fourth, the smooth transition of National IV products has enhanced the industrial upgrading and development capabilities and formed new market competitiveness, which will further promote the structural transformation, product upgrading, and innovation-driven development of China's agricultural machinery industry.

Market prospects of the passenger car seats:

Lightweight becomes a new development trend: With the continuous promotion of the national energy-saving and emission-reduction policy and the continuous development of the new energy vehicle industry, improving the fuel economy of fuel-powered vehicles and the cruising range of new energy vehicles through lightweight has become a new development trend. The lightweight of automotive seats is mainly achieved through the lightweight of its various components. Currently, methods to achieve lightweight include the application of new materials and the optimization of structural design. Through the lightweight of components, the lightweight of automotive seats can ultimately be achieved to improve energy consumption economy and achieve energy-saving and emission-reduction.

Higher requirements for functionality and comfort brought about by industry development: With the continuous progress of the automotive industry, new energy and intelligence have become new development trends, and the automotive consumer group is increasingly younger, with the gradual upgrading of automotive consumption preferences. In this context, as one of the parts with the closest contact between drivers and passengers and the vehicle, automotive seats are put forward with higher requirements for functionality and comfort. Through the comprehensive supporting of automotive seat components, providing higher comfort for drivers and passengers and adding more adjustment and personalized functions have become new development trends.

In the next few years, the global passenger car seat market is expected to maintain a growth trend. It is estimated that by 2025, the market scale of passenger car seats in China will reach 150 billion yuan, with an average annual growth rate of 17%. The global passenger car seat market scale will reach 380.2 billion yuan, with an average annual growth rate of 5.0%.

The passenger car seat market continues to grow in scale, the competition pattern is diversified, the technological trend is towards lightweight, intelligent, and comfortable development, and the market prospects are optimistic in the next few years.

1.1.3 Technical analysis

The production technology of seats mainly includes the following key links:

Skeleton manufacturing: The seat frame is made of steel plates through stamping technology and is fixed at the designated position in the vehicle using a screw-welding process. The stamping technology ensures that the skeleton type perfectly matches the vehicle seat design, and all materials meet high-standard composite requirements.

Welding Technology: Welding is a key connection method in seat manufacturing, especially in positions such as seat frames, recliners, and support frames that bear relatively large stresses. The welding quality directly affects the safety and service life of the seat.

Finishing Process: The seat frame is painted using an automatic electrostatic powder spraying technology. The powder needs to be dried before entering the seat assembly stage to ensure that the coating is uniform, beautiful, and durable.

Sponge Foaming Treatment: The sponge foaming process for the backrest and seat cushion parts includes multiple links such as mold cleaning, release agent spraying, casting, curing heating, and mold opening for part removal, ensuring the stable and reliable quality of the sponge.

Fabric Treatment: The seat fabric usually adopts a sewing process, including steps such as laminating and cutting, single-piece sewing, overall sewing, inspection, and assembly, ensuring that the fabric quality complements the overall seat quality.

Assembly Process: The seat assembly involves placing the frame on the production line, clamping the slides and connecting the seat, unlocking the tooling and the backrest adjustment handle, and completing packaging before leaving the production line. The detailed processing of each link ensures that the seat assembly quality reaches the best level.

1.1.4 Advantageous conditions of project construction

(1) Policy advantage

To promote the technological progress of agricultural vehicles, the state encourages enterprises to increase R&D investment and develop new-type agricultural vehicles. By providing technical support, financial support, and other means, the innovative development of the agricultural vehicle industry is promoted.

Jilin Province has established a production-finance cooperation consultation mechanism among banks, enterprises, and insurers, relying on financial institutions to build a characteristic financial service platform, promoting financing guarantee services, and supporting the development of key projects of parts enterprises.

Siping City is committed to building a 100-billion-yuan automotive industry. Through the "South-Connecting and North-Integrating" strategy, it conducts economic and trade exchanges and cooperation with Changchun and Shenyang to promote the agglomeration of industrial clusters. Siping City regards accelerating the development of the automotive industry as a strategic measure for accelerating transformation, rapid growth, and full revitalization. Taking the park as the carrier, it develops characteristic economies and forms three major industrial chains of special-purpose vehicles, automotive parts, and coaches.

Siping City encourages enterprises to invest in automotive seat production projects through measures such as financial support and tax preferences. Specific policy details may include capital subsidies and tax exemptions for new-built or expanded projects.

These policies provide a good development environment and support for the automotive seat production project in Siping City, help attract more investors and enterprises to settle in, and promote the development of the local automotive industry.

(2) Industrial advantage

Siping is one of the two major equipment manufacturing industry bases in Jilin Province and the cradle of China's large-scale combine harvesters, large-scale high-temperature fans, refitted vehicles, and city buses. In recent years, the automotive parts industry in Jilin Province has developed rapidly. There are more than 400 automotive parts enterprises above designated size in the province, and there are more than 3,500 types of automotive parts supporting products. It covers various fields such as the power system, body system, chassis system, automotive electronics, and new energy, and has initially formed an industrial pattern with Changchun and Jilin as the core and multi-point coordinated development in Siping, Liaoyuan, Songyuan, etc.

(3) Location advantage

Siping City is located in the southwest of Jilin Province, in the central hinterland of the Songliao Plain. It is an important transportation hub and logistics node city in Northeast China, at the junction of Liaoning, Jilin, and Inner Mongolia. It is the only way for Jilin, Heilongjiang, and the eastern part of Inner Mongolia to reach coastal ports and the Bohai-Rim Economic Circle, with unique geographical advantages.

The transportation facilities are also very complete. As a transportation hub city, Siping has a convenient railway, highway, and aviation transportation network. In terms of railways, Siping is the intersection of the Harbin-Dalian Railway and the Changchun-Tumen Railway, connecting the main cities and ports in Northeast China. In terms of highways, Siping has multiple expressways and national highways, such as the Beijing-Harbin Expressway and the Changchun-Shenyang Expressway, which facilitate traffic connections with the surrounding areas. In addition, Siping City is also planning and constructing an airport to further enhance its air transportation capacity.

These transportation facilities and geographical location make Siping City an important logistics center and transportation hub in Northeast China, promoting the development of the regional economy and the convenient flow of people and logistics.

The Economic Development Zone of Siping City has convenient transportation. It is located in the eastern suburbs of Siping City. The Harbin-Dalian Expressway, National Highway 303, and National Highway 102 pass through the zone. The expressway entrance and exit, Siping East High-speed Railway Station, and East High-speed Passenger Transport Station are all located in the development zone. In addition, Siping City also has a military-civilian joint-use airport, which further improves its transportation convenience.

(4) Talent advantage

The provincial-level Siping Hongzui University Science and Technology Park, jointly established by Jilin Normal University and Hongkai District, is a powerful carrier for serving the economic development and construction of the zone. As a key university in Jilin Province, Jilin Normal University has signed long-term talent-cultivation cooperation agreements with Hongkai District, providing outstanding high-end talent resources for the development of our zone.

Hongkai District is home to four major technical secondary schools and is an important output place for professional technicians. Siping Vocational and Technical Education Center, Jilin Agricultural Engineering Vocational-Technical College, Jingong Technical School, etc. are constantly outputting outstanding talents with excellent professional skills to society. They have all signed long-term talent-cultivation cooperation agreements with Hongkai District and can provide professional technical talent guarantees for enterprises in the zone.

On the basis of meeting the needs of high-end talents and professional technical talents, Hongkai District has two administrative villages under its jurisdiction, storing a large number of ordinary workers. Compared with the economically developed southern regions, Hongkai District has sufficient labor force, low labor costs, and guaranteed talent resources, which can meet the large-scale ordinary labor needs of enterprises.

1.2 Contents and scale of project construction

The overall planned area of the project is 50,000㎡. New production workshops, R&D buildings, and supporting facilities will be built, and 150 sets of main and auxiliary production and R&D equipment such as automotive front and rear seat assembly production lines, welding robots, ring-shaped dual-robots, and vibration analyzers will be purchased. The production capacity of an annual output of 400,000 sets of agricultural vehicle and passenger car seats will be formed.

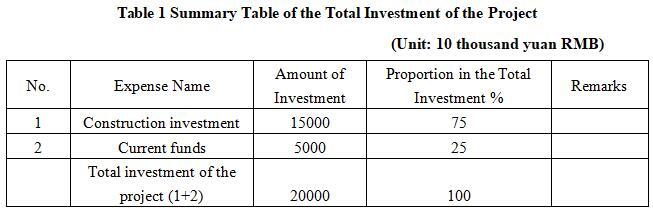

1.3 Total investment of the project and capital raising

The total investment of the project is 200 million yuan, including the construction investment of 150 million yuan.

1.4 Financial analysis and social evaluation

1.4.1 Main financial indexes

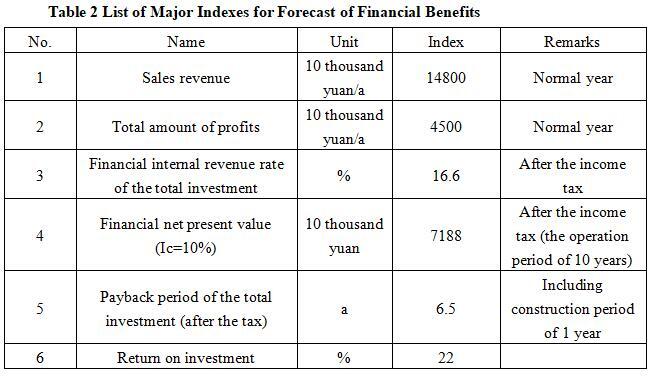

After the project reaches the production capacity, its annual sales income will be 148 million yuan, its profit will be 45 million yuan, its investment payback period will be 6.5 years (after the tax, including construction period of 1 year), and its return on investment will be 22%.

Note: “10 thousand yuan” in the table is in RMB.

1.4.2 Social evaluation

Boosting employment and economic development: The construction of the seat production project will directly create a large number of job opportunities in aspects such as production, assembly, and logistics. This helps alleviate local employment pressure and increase residents' income levels. Moreover, the development of related industrial chains will also drive the prosperity of the surrounding economy, contributing to the overall growth of the local economy.

Enhancing regional economic competitiveness: By building a project for producing agricultural vehicle and passenger car seats, it can promote the development of the local automotive parts industry and form an industrial cluster effect. This not only helps enhance the competitiveness of the regional economy but also attracts more investment and cooperation opportunities, further promoting the diversification and sustainable development of the local economy.

Propelling technological innovation and industrial upgrading: The construction of the seat production project will facilitate the research and development as well as the application of relevant technologies, driving technological innovation and upgrading of the industry. By introducing advanced equipment and technologies, production efficiency and product quality can be improved to meet the market demand for high-quality seats, thus enhancing the competitiveness of the entire industry.

1.5 Cooperative way

Sole proprietorship, joint venture or cooperation.

1.6 What to be invested by the foreign party

Capital, other ways can be discussed in person.

1.7 Construction site of the project

The planned construction site of the project is Siping Hongzui Economic and Technological Development Zone.

1.8 Progress of the project

The project proposal has been prepared.

2. Introduction to the Partner

2.1 Unit basic information

Name: Siping Hongzui Economic and Technological Development Zone

Address: No. 1, Xinghong Road, North Yingbin Street, Siping City, Jilin Province

2.2 Unit overview

Siping Hongzui Economic and Technological Development Zone was established in 2001, promoted to a provincial-level development zone in 2002, and upgraded to a national-level development zone with the approval of the State Council in 2010. It is located in the northwest of Siping urban area, Jilin Province, the central city of the Northeast Asia Economic Circle, with a total planned area of 21.35 square kilometers.

As the only national-level development zone in Siping City, Hongkai District gives full play to its leading and guiding role, taking the lead in piloting the agglomerated development of industries. In particular, centering around the important speeches and instructions of General Secretary Xi Jinping during his inspection of Jilin and Siping, Hongkai District has made great efforts in black-land protection, gradually emerging as a rising area for modern agricultural machinery industry in Siping City, a demonstration zone for innovation and transformation of foreign investment and foreign trade, a pilot zone for the integrated development of Siping and Lishu, and an agglomeration area for characteristic equipment manufacturing. It is a growth pole for Siping's north-ward development.

During the "14th Five-year Plan" period, guided by the "Siping City Industrial Layout Action Outline", and combining its original industrial foundation and future development direction, Hongkai District follows the overall concept of "intensive development, innovative development, efficient development, and green development". It focuses on developing three leading industries: equipment manufacturing, new building materials, and modern logistics, and emphasizes the layout of "one base and three parks". The "one base" refers to the Innovation and Demonstration Base for Agricultural Machinery Industry in China's Black-land Protection. With a planned area of 4.4 square kilometers and a total planned investment of 10.9 billion yuan, it aims to build a modern agricultural equipment industry base integrating high-end manufacturing, scientific research and innovation, and supporting services. The "three parks" include the Equipment Manufacturing Industrial Park, which focuses on heat exchange, environmental protection, packaging, safety equipment, agricultural machinery, construction machinery, rubber and plastic products, etc.; the Modern Logistics and Warehousing Industrial Park, which focuses on agricultural machinery warehousing and logistics, warehousing transactions, and bulk agricultural and sideline products business logistics; and the New Materials Industrial Park, which focuses on the transformation and upgrading and technological transformation of new wall materials, new waterproof and sealing materials, new thermal insulation materials, decoration materials, and non-ferrous metals, as well as the comprehensive utilization of construction waste and waste recycling. At the same time, Hongkai District accelerates the cultivation and development of emerging industries such as digital technology, healthy food, and medicine, striving to build itself into an agglomeration area for high-end industries, a leading area for taking the lead in development, and a bridgehead for transformation and upgrading in the whole city.

2.3 Contact method

Contact method of the county (city) where the project is located:

Contact unit: Siping Hongzui Economic and Technological Development Zone

Contact person: Zhang Xinghe

Tel: +86-15944407999

E-mail:

Contact method of the city (prefecture) where the project is located:1226160403@qq.com

Contact unit: Economic Cooperation Bureau of Siping City

Contact person: Wen Dacheng

Tel: +86-434-3260536

E-mail: spjhjjhk@163.com