Equipment Manufacturing

Ultra-high-end CNC Machine Tool Equipment Construction Project of Siping City

1. Introduction to the Project

1.1 Project background

1.1.1 Product introduction

With the continuous advancement of science and technology, more stringent requirements have been put forward for the quality and production efficiency of mechanical products, and the speed of product renewal and iteration is also accelerating. Therefore, the transformation of CNC machine tools has become particularly important. The design and transformation of CNC machine tools have become a key area in industrial development. Milling machines have a very wide range of applications and are mainly used for processing flat surfaces or formed surfaces. However, when it is necessary to process special-shaped planes such as arcs and cams on a vertical milling machine, machine tool accessories such as circular worktables and dividing heads must be used, and the overall adjustment of the machine tool is required. This usually leads to a reduction in processing accuracy and cumbersome basic adjustment work. Therefore, in order to improve the processing accuracy of workpieces, ensure product quality, and simplify the process of processing complex shapes such as arc surfaces and cam surfaces, it is particularly necessary to use CNC technology to transform the milling machine into a CNC milling machine.

1.1.2 Market prospect

(1) Current situation of CNC machine tool market

Machine tools, also known as machine-building machines or tools, are machines that manufacture machines and are usually classified into metal-cutting machine tools, forging machines, woodworking machine tools, etc. In modern mechanical manufacturing, in addition to cutting processing, there are also various processing methods such as casting, forging, welding, stamping, and extrusion. However, for parts with high precision requirements and fine surface roughness requirements, final processing is usually required on a machine tool through cutting methods.

CNC machine tools, that is, numerically controlled machine tools, are automated machine tools equipped with a program control system. This system can logically process programs with control codes or other symbolic instructions, decode them, and thus control the operation of the machine tool and process parts.

CNC machine tools perform outstandingly in solving the processing problems of complex, precise, small-batch, and multi-variety parts. They are flexible and high-performance automated machine tools, representing the development direction of modern machine tool control technology and being typical mechatronic products. There are a wide variety of CNC machine tools, which can be classified according to different classification methods. The most common ones include CNC lathes, CNC milling machines, CNC machining centers, CNC drilling machines, CNC grinding machines, CNC gear processing machine tools, etc. These machine tools are widely used in the metal-cutting field, from basic part processing to the manufacture of complex shapes, meeting the diverse needs of different industries.

From the perspective of application fields, high-end CNC machine tools are widely used in key pillar industries related to national security such as energy, aerospace, military, and shipbuilding. At the same time, the acceleration of industrial upgrading in downstream key industries such as automobiles, aerospace, and medical equipment has further increased the demand for high-end CNC machine tools. China's manufacturing industry is transforming from a "bug manufacturing country" to a "strong manufacturing country". In the future, the development trend of China's manufacturing industry is to replace "small profits but quick turnover" with "high-end and high-profit," and the proportion of demand for high-speed, high-precision, and high-value high-end CNC machine tools will also become higher and higher. At present, Western countries have strictly restricted the export of high-end CNC machine tools and technologies to China, resulting in China facing the "bottleneck" problem in the high-end CNC machine tool industry. The intensification of Sino-US trade frictions has further accelerated China's process of promoting the localization of high-end machine tools and achieving independent control of high-end products. In recent years, a number of private enterprises with certain core technologies have emerged in the domestic mid-high-end CNC machine tool market. In the future, they will follow the trend of domestic substitution and further expand their share in the high-end market.

Judging from the revenue scale of the CNC machine tool business of major enterprises in the CNC machine tool industry, in 2023, the CNC machine tool revenues of Chuangshi Technology and Haitian Precision Machinery reached 3.43 billion yuan and 3.27 billion yuan respectively, ranking leading; the CNC machine tool revenue of Yawei Co., Ltd. was 1.93 billion yuan, that of Qinchuan Machine Tool reached 1.78 billion yuan, and the revenue of Rifeng Precision Machinery was also over 1 billion yuan, showing certain competitive advantages.

(2) Market prospect of CNC machine tools

The Outline of the 14th Five-year Plan clearly states that it is necessary to promote the optimization and upgrading of the manufacturing industry, cultivate advanced manufacturing clusters, and promote the innovative development of industries such as integrated circuits, aerospace, ship and ocean engineering equipment, robots, advanced rail transit equipment, advanced power equipment, construction machinery, high-end CNC machine tools, medicine, and medical equipment; develop and strengthen strategic emerging industries, focus on seizing the opportunities of future industrial development, cultivate leading and pillar industries, and promote the integration, clustering, and ecological development of strategic emerging industries, with the added value of strategic emerging industries accounting for more than 17% of GDP. Related equipment such as automobiles, integrated circuits, aerospace, ships, and robots all need to use CNC machine tools for refined supporting production. Overall, with the continuous enrichment of the types of China's advanced manufacturing industries, the demand for the CNC machine tool industry in China is gradually increasing.

The "Made in China 2025" strategic program clearly states that "by 2025, the numerical control rate of key processes in China will be increased from the current 33% to 64%." Under the influence of factors such as policy encouragement, economic development, and industrial upgrading, the CNC machine tool industry in China will usher in broad development space in the future.

Driven by the wave of globalization and digitalization, machine tools, as the core equipment of the manufacturing industry, are experiencing unprecedented changes and development. As the "machine-building machine of industry," the accuracy, efficiency, and intelligence level of machine tools directly determine the overall competitiveness of the manufacturing industry. In recent years, with the gradual recovery of the global economy and the rise of emerging markets, the demand for the machine tool market has continued to grow. At the same time, with the rise of technologies such as intelligent manufacturing and industrial Internet, the machine tool industry has ushered in unprecedented growth opportunities, with the market scale continuing to expand and technological innovations emerging one after another. In 2023, the global machine tool sales revenue was approximately 52.717 billion US dollars. In the future, facing fierce market competition and rapidly changing market demands, machine tool enterprises will continue to innovate technologies, optimize product structures, and improve service quality, leading the machine tool industry to develop in the direction of high-end, intelligent, and green, and promoting the growth and development of the industry.

The market prospect of ultra-high-end CNC machine tool equipment is broad, especially the demand in the high-end manufacturing field will continue to grow. Foreign brands still dominate, but domestic enterprises are also constantly striving to improve their technical levels and market shares. In the future, intelligence and automation will become important trends in the development of ultra-high-end CNC machine tool equipment.

1.1.3 Technical analysis

The project plans to introduce technology enterprises with relatively mature technologies, which are leading scientific and technological enterprises specializing in the research, development, and manufacture of high-precision metal milling CNC machine tools and providing high-difficulty and high-precision metal milling processing. The project can draw on the mature technologies of Shenyang Sigma and Beijing Beiyi CNC Machine Tool Company.

Liaoning Sigma CNC Machine Tool Co., Ltd. is a scientific and technological company dedicated to the research, development, production, sales, and service of high-precision CNC machine tools. The company has more than 120 sets of advanced production and testing equipment such as CNC gantry machining centers, CNC gantry guideway grinders, CNC lathes, CNC milling machines, coordinate measuring machines, and laser interferometers. The company's leading products include several series such as the CT series horizontal lathes, VT series vertical lathes, QT series turning and milling compound centers, VMT series five-axis turning and milling compound machining centers, and special CNC machine tools, with more than 20 models of different specifications. The company's main products serve the production and processing of parts in industries such as automobiles, electric vehicles, construction machinery, rail transit, aerospace, and agricultural machinery.

In recent years, the enterprise has implemented an innovation strategy and plan and achieved breakthroughs in several technical fields of CNC processing equipment. The enterprise has 14 independently developed patented technologies, including 12 invention patents and 2 utility model patents, laying a solid foundation for the enterprise's technological innovation and continuously improving its market competitiveness.

Honors obtained by the enterprise: a national-level "specialized, refined, characteristic, and innovative" little giant enterprise, a national advanced employment unit, a national worker pioneer, a national high-tech enterprise, a national intellectual property advantage enterprise, a provincial gazelle enterprise, a provincial patent demonstration enterprise, a provincial enterprise technology center, a provincial professional technology innovation center, a provincial innovative small and medium-sized enterprise, and a "top 100 enterprise" in the city. The "Sigma" brand CNC machine tool has won the famous trademark of Liaoning Province. In 2008, the enterprise passed the ISO9001 quality system certification, and in 2023, the enterprise passed the ISO14001 environmental system and ISO45001 occupational health and safety management system certifications.

Beijing Beiyi CNC Machine Tool Co., Ltd. is a wholly-owned subsidiary of Beijing Beiyi Group Co., Ltd. It is a sales base for precision CNC machine tools and complex process production lines in China, a key enterprise in the Chinese machine tool industry, with a glorious history and has contributed to the development of industrial infrastructure construction. The Chinese machine tool industry has gone through the efforts of several generations and has completed the process that took two centuries in developed countries in the world in 60 years. Now it has a pivotal voice and industrial status in the international community and is realizing the transformation from "Made in China" to "Created in China."

The main products sold by Beiyi CNC include: CNC gantry boring and milling machines, CNC floor boring machines, CNC vertical lathes, and guideway grinders for heavy machine tool products; CNC milling machines, CNC grinders, CNC lathes, machining centers, turning and milling compound machines, laser engraving machines, drilling centers, five-axis linkage blade/impeller machining centers, CNC honing machines, high-precision cylindrical grinders, CNC grinders, ordinary cylindrical grinders, special grinders, superfinishing machines, automatic production lines, ordinary milling machines, complete sets of equipment, and functional components for medium-sized machine tool products. The products are widely used in industries such as automobiles, aerospace, ships, power generation, rail transit, molds, and machinery.

1.1.4 Advantageous conditions of project construction

(1) Policy advantage

The "Catalogue for the Guidance of Industrial Structure Adjustment (2024 Edition)": clearly lists high-end CNC machine tools as encouraged industries.

The "Implementation Plan for Promoting Equipment Updating in the Industrial Field": proposes that by 2027, the equipment investment scale in the industrial field will increase by more than 25% compared with 2023, and promote the update and upgrading of industrial equipment such as CNC machine tools.

The Department of Industry and Information Technology and the Department of Finance of Jilin Province jointly issued relevant notices to support the intelligent transformation and digital transformation of the manufacturing industry. The policy support scope includes projects constructed with loans or self-owned funds. The discount standard is 100% of the actual loan interest rate. The annual discount scale for a single enterprise does not exceed 5 million yuan, and the discount period does not exceed two years.

Siping promotes large-scale equipment updates and the replacement of consumer goods with new ones, aiming to promote the high-end, intelligent, and green development of industries. By 2027, the equipment investment scale in fields such as industry, agriculture, construction, transportation, education, culture and tourism, and medical care will increase by more than 25% compared with 2023. The policy focuses on supporting equipment update and transformation in the industrial field, promotes intelligent manufacturing equipment, advances "intelligent transformation and digital transformation," and implements green equipment upgrades to promote the green transformation of key industries.

The Science and Technology Bureau of Siping City solicits project guideline suggestions from enterprises in the industrial high-tech field, focusing on supporting the research, development, and application of key technologies such as new manufacturing, new materials, new optoelectronics, and the new generation of information technology.

(2) Industrial advantage

Siping has a complete industrial chain and supporting system. After years of development, the characteristic equipment industry in Siping has formed four pillar industries mainly including heat exchangers, auto parts (special vehicles), agricultural machinery, and machining, and has established a relatively complete industrial chain and supporting system. This complete industrial chain and supporting system provide strong support for the production of CNC machine tool equipment.

Siping also has significant advantages in technological innovation. Siping Machinery, a well-known domestic machinery manufacturing enterprise, has been committed to the research and development and application of CNC technology, and has a professional CNC technology team and advanced CNC machine tool equipment. The enterprise has core technologies with independent intellectual property rights in CNC systems, servo drives, precision processing, etc., providing strong technical support for the sustainable development of the enterprise.

(3) Location advantage

Siping is located in the southwest of Jilin Province, in the central hinterland of the Songliao Plain. It is an important transportation hub and logistics node city in Northeast China. It is at the junction of Liaoning, Jilin, and Inner Mongolia, and is the only way for Jilin, Heilongjiang, and the eastern part of Inner Mongolia to reach coastal ports and the Bohai Rim Economic Circle, enjoying unique geographical advantages.

The transportation facilities are also very complete. As a transportation hub city, Siping has a convenient railway, highway, and air transportation network. In terms of railways, Siping is the intersection of the Harbin-Dalian Railway and the Changchun-Tumen Railway, connecting the main cities and ports in Northeast China. In terms of highways, Siping has several expressways and national roads, such as the Beijing-Harbin Expressway and the Shenyang-Changchun Expressway, facilitating traffic connections with surrounding areas. In addition, Siping is planning to build an airport to further enhance its air transportation capacity.

These transportation facilities and geographical location make Siping an important logistics center and transportation hub in Northeast China, promoting the development of the regional economy and the convenient circulation of people and goods.

(4) Talent advantage

Siping has many universities such as Jilin Normal University, Boda College of Jilin Normal University, Jilin Agricultural Engineering Vocational and Technical College, Siping Vocational University, the Hongzui Vocational and Technical College being established, Siping Medical College of Jilin University, and Siping Radio and Television University. Among them, Jilin Normal University is a key university in Jilin Province, with 16,302 full-time undergraduate students, 1,844 postgraduate students, 336 international students, and 15,131 adult education students. It can cultivate thousands of high-level talents for the society every year. Surrounding cities such as Changchun, Harbin, and Daqing have many universities, which can provide more than 500,000 high-level talents annually. These talents can provide technical support for the project construction.

The Economic Development Zone of Siping has a rich talent reserve and good talent introduction policies. In recent years, Siping has adhered to the development concept that "talents are the primary resource." Through the implementation of the "Talent Attack Plan" and the "Ten Thousand College Students Staying in Siping Plan," it has successfully introduced more than 500 master's and doctoral talents and more than 11,200 college graduates. The Economic Development Zone of Siping also attaches importance to school-enterprise cooperation and realizes the seamless connection between the talent training achievements of colleges and universities and the talent needs of enterprises through "targeted" employment precise connection.

1.2 Contents and scale of project construction

The project covers an area of 30,000㎡. CNC machine tool production base and vortex disc processing center will be constructed.

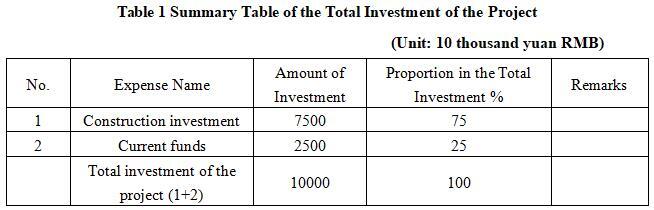

1.3 Total investment of the project and capital raising

The total investment of the project is 100 million yuan, including the construction investment of 75 million yuan.

1.4 Financial analysis and social evaluation

1.4.1 Main financial indexes

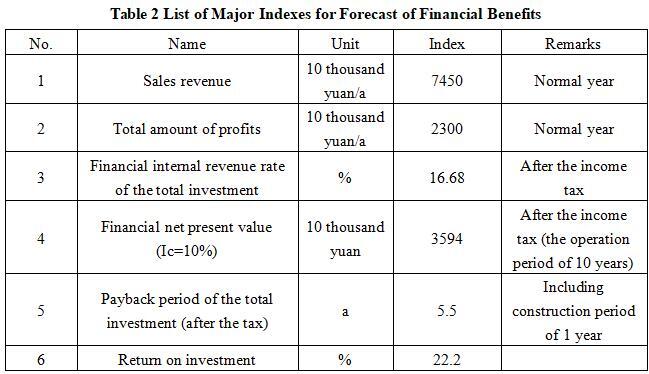

After the project reaches the production capacity, its annual sales income will be 74.5 million yuan, its profit will be 23 million yuan, its investment payback period will be 5.5 years (after the tax, including construction period of 1 year), and its return on investment will be 22.2%.

Note: “10 thousand yuan” in the table is in RMB.

1.4.2 Social evaluation

Facilitate the structural adjustment and upgrading of the manufacturing industry: The application of CNC machine tools promotes the production of products with high technological content and high added value, facilitates the structural adjustment and upgrading of the manufacturing industry, and improves the overall technological level and product quality of the manufacturing industry.

Enhance product quality and production efficiency: Ultra-high-end CNC machine tool equipment has the advantages of high production capacity and low production costs, which can significantly improve product quality and production efficiency, meeting the needs of high-end manufacturing.

Reduce environmental pollution: The popularization and application of CNC machine tools contribute to reducing environmental pollution. The efficient production process reduces energy consumption and waste emissions, which is in line with the requirements of sustainable development.

Improve the skill level of workers: The use of CNC machine tools requires highly skilled labor, which promotes the improvement of workers' skills, increases employment opportunities, and raises workers' income levels and quality of life.

1.5 Cooperative way

Sole proprietorship, joint venture or cooperation.

1.6 What to be invested by the foreign party

Capital, other ways can be discussed in person.

1.7 Construction site of the project

Siping Economic Development Zone

1.8 Progress of the project

The project proposal has been prepared.

2. Introduction to the Partner

2.1 Unit basic information

Name: Management Committee of Siping Economic Development Zone

Address: No. 1699, Kaifa Road, Siping Economic Development Zone

2.2 Unit overview

Siping Economic Development Zone covers an area of 71.41 square kilometers. It mainly cultivates three leading industries: medical and health green food (big health), automobiles and equipment manufacturing, and modern services. There are currently 951 industrial and commercial registered enterprises in the zone. The economic development zone has 12 high-tech enterprises, 10 provincial-level specialized, refined, characteristic, and innovative enterprises, 12 provincial-level technology research and development centers, and 6 provincial-level science and technology small giant enterprises. It has 3 well-known trademarks in China, 5 provincial-level famous trademarks, 7 provincial-level famous brand products, and has obtained more than 100 invention patents.

The development zone enjoys superior transportation and geographical location, as well as a solid industrial foundation. As one of the old industrial bases in Northeast China, Siping has a solid industrial foundation in medical food, automobiles and equipment manufacturing, and modern services. Well-known domestic enterprises such as AVIC, Junlebao, Dayao, and Baixiang have invested in the zone. The infrastructure is complete. Investment elements such as water, electricity, gas, heating, heat, and communication are abundantly supplied and are at a low-price standard in the whole province. There is an ample talent reserve. Two institutions of higher learning within the jurisdiction can provide talent reserves for the development of enterprises, and various vocational schools can provide customized talent training for enterprises, ensuring the sustainable development of enterprises.

Siping Economic Development Zone has always adhered to high-starting-point planning and high-standard construction, forming a “12345” industrial spatial layout with clear positioning, distinct characteristics, division of labor, cooperation, and staggered development. It is committed to creating a leading area for high-end services in Siping, a core area for new industries, a pioneer area for kinetic energy conversion, and an important carrier area for comprehensive opening up, and becoming an eastern business and logistics economic center of Siping urban area and an eastern growth pole of the central urban area of Siping.

“One-Core Driving”: Taking areas such as Development Zone Avenue, Ziqi Avenue, Kaiyun Street, and Wanda Business Circle as the core, modern service industries such as commerce, finance, maker, and headquarters are arranged to create a central business core area and an urban appearance display area of Siping.

“Two-Wing Agglomeration”: On the south side, taking the Siping-Changchun jointly-built automobile industrial park as the carrier, the automobile and equipment manufacturing industry is arranged; on the north side, taking the medical and green food incubator as the carrier, the medical and health green food industry is arranged, achieving the coordinated development of the two wings.

“Three Major Plates”: Every effort is made to build three development plates of automobile and equipment manufacturing, medical and health green food, and modern service industries, building the “backbone” of the development of the economic development zone.

“Four-Zone Linkage”: Adhering to the integration and linkage concept of “establishing the zone with industry, revitalizing the zone with commerce, activating the zone with reform, and strengthening the zone with science and technology”, it strongly promotes economic construction to enter the “fast lane” of development.

“Five-Park Support”: The five parks, namely, the medical and health green food industrial park with a planned area of 11.16 square kilometers, the automobile and equipment manufacturing industrial park with a planned area of 21.43 square kilometers, the industry-city integration park with a planned area of 16.54 square kilometers, the municipal facilities supporting park with a planned area of 5.11 square kilometers, and the industry-education-health-care demonstration park with a planned area of 2.49 square kilometers, serve as the carriers of the industrial chain. At the same time, there are three incubation platforms for the medical industry, green food industry, and automobile and parts industry to undertake the landing of projects.

Adhering to the principles of “industrial supporting, complete facilities, policy support, and service-oriented”, and starting from the project needs, the development zone gives full play to the carrier function of project construction and meets the actual investment needs of enterprises in three ways. First, self-investment and self-construction. Obtain the land use right through transfer and form fixed-asset investment. Second, light-asset investment. Enter the incubation platform through lease to meet the needs of enterprises for rapid production and efficiency. Third, enclave economy. Through regional economic cooperation, transfer funds, technology, and projects to achieve complementary resources and tax sharing.

2.3 Contact method

Contact person of the project unit: Hu Jing

Tel: +86-13844400042

Contact method of the city (prefecture) where the project is located:

Contact unit: Economic Cooperation Bureau of Siping City

Contact person: Wen Dacheng

Tel: +86-434-3260536

E-mail: spjhjjhk@163.com