Medicine & Health

Medical Facial Mask Cold Compress Production Construction Project of Changchun City

1. Introduction to the Project

1.1 Project background

1.1.1 Product introduction

Medical facial mask, also known as medical cold compress, is a kind of medical skin care product. Its main function is to replenish water and preserve moisture, remove pigmentation, improve skin firmness, lighten fine lines, and repair damaged skin. It is produced aseptically, with mild ingredients and no irritating substances. It can improve dry skin, inhibit pigment formation, promote metabolism, improve dullness, supplement nutrients, improve fine lines and wrinkles, and repair allergic skin.

The project is planned to be located in the Nong’an Industrial Concentration Zone, covering a total area of 30,000 square meters. After the project is put into production, the annual production scale of medical facial mask cold compress will be 5 million.

1.1.2 Market prospect

(1) Function and efficacy of medical facial mask cold compress

Medical facial mask cold compress is a medical-grade product specially designed for skin care. It can not only provide immediate soothing effect, but also improve the skin condition after long-term use. This kind of facial masks usually contain high concentration of active ingredients, such as hyaluronic acid, and collagen, etc., which can penetrate into the bottom layer of the skin, promote cell regeneration, and enhance the skin’s self-repairing ability.

In addition to basic moisturizing and repairing functions, the medical facial mask cold compress also has anti-inflammatory and sedative effects. For skin problems such as inflammation, acne and postoperative repair, etc., this kind of facial mask can effectively reduce redness and pain, and accelerate the healing process. In addition, due to its mild ingredients, it is suitable for various skin types, including sensitive skin.

With the progress of science and technology, the medical facial mask cold compress is also of constant innovation. For example, the facial masks added with nanotechnology can more accurately deliver the effective ingredients to the deep skin. In the future, with the deepening of research, medical facial mask cold compress is expected to play a greater role in the field of skin treatment and care.

(2) Market prospect analysis of medical facial mask cold compress

With the significant improvement of people’s living standards and the continuous enhancement of health awareness, medical facial mask cold compress, as an emerging skin care product, is gradually well received and sought after by the consumers. Its market potential is not only reflected in the unique efficacy of the product itself, but also closely related to current consumption trend and the development trend of the medical beauty industry.

Medical facial mask cold compress is characterized by quick repair of damaged skin and effective relief of skin discomfort, which can meet the urgent demands of modern people for immediate effects in fast-paced life. Secondly, with the vigorous development and growing popularity of the medical beauty industry, more and more consumers will choose to use medical facial masks to assist the skin recovery process after various cosmetic surgeries, which undoubtedly provides a huge growth potential and expansion space for the market of medical facial mask cold compress.

In addition, the market growth of medical facial mask cold compress also benefits from its scientific and safe ingredients. These facial masks usually contain strictly selected ingredients, such as hyaluronic acid, and collagen, etc. They can penetrate into the bottom layer of the skin, and promote cell regeneration, thus accelerating the healing process. Compared with traditional beauty products, the ingredients of medical facial mask cold compress are more streamlined, and reduce the risk of allergy and irritation, making them particularly popular among people with sensitive skin.

With the increasing attention of the consumers to the safety of personal care products, there is a broader market prospect of medical mask cold compress. The brand owners and manufacturers are also making constant innovation to introduce more special facial masks for different skin problems, such as acne, sunburn, and postoperative repair, etc. These products not only meet the consumers’ demand for immediate results, but also reflect the trend of personalized and professional skincare.

In the future, with the progress of science and technology and the diversification of consumer demands, medical facial mask cold compress is expected to achieve more breakthroughs in ingredients, functions and use experience. For example, improving the absorption efficiency of ingredients through nano-technology, or using intelligent materials to achieve temperature regulation to provide more comfortable user experience. These innovations will bring new growth points to the market of medical facial mask cold compress, and also bring more safe and effective skin care options to the consumers.

To sum up, medical facial mask cold compress has a very broad market prospect, but it is also facing fierce market competition and various challenges. Only by making constant innovation and optimizing market strategies can it occupy a favorable position in competition and achieve long-term sustainable development.

(3) The necessity of project construction and advantages of the project

First of all, as an efficient and safe skin care product, there is a broad development space for medical facial mask cold compress in the market. With the increasing requirements of the consumers for improvement of the quality and effect of skin care products, medical facial mask cold compress has gradually become the focus of attention in the market with its unique efficacy and advantages. The necessity of project construction is that through large-scale and professional production, it can meet the huge demand for high-quality medical facial mask cold compress in the market, and also help to improve the production level and product quality of the whole industry. Specifically, the medical facial mask cold compress not only performs well in the fields of post-operative repair and acne treatment, etc., but also can effectively alleviate skin problems such as sunburn and sensitivity, etc. It is well-received by the consumers due to its mild and non-irritating characteristics. Especially in the context of increasing skin problems caused by current environmental pollution and lifestyle changes, the market demand for medical facial mask cold compress shows a trend of rapid growth. Therefore, the construction of a project specializing in the production of medical facial mask cold compress can not only fill the gap in the market, but also promote the technological progress and innovation of the industry, providing the consumers with more high-quality options.

Secondly, the construction of the project has significant advantages. On the one hand, relying on advanced production technology and equipment, the project can achieve efficient and precise production, and guarantee the product quality and stability. By adopting the latest nano-technology and intelligent materials, the project can achieve significant breakthroughs in absorption efficiency of ingredients and user experience. For example, by refining the effective ingredients to the nano-level through nano-technology, the skin’s absorption rate can be greatly improved; Using intelligent materials to achieve temperature regulation can make the facial mask maintain a suitable temperature during use all the time, providing more comfortable use experience. On the other hand, the project has abundant market resources and sales channels, which can quickly push the product to the market and achieve good sales performance. By establishing close partnerships with major e-commerce platforms, professional beauty institutions, and medical institutions, etc., the project can quickly capture the market share and expand the brand influence. In addition, the project also has a perfect quality management system and after-sales service system, which can provide the consumers with all-around service guarantee. Every link is strictly controlled from the purchase of raw materials to the ex-factory of the finished products, to ensure that every facial mask meets the high-standard quality requirements; Meanwhile, professional customer service team is established to promptly address the consumers’ inquiries and feedback, and enhance the user experience. These comprehensive advantages will lay a solid foundation for the successful implementation and long-term development of the project.

1.1.3 Technical analysis

The project shows significant progressiveness in terms of technical level. First of all, the application of nano-technology enables the effective ingredients in the facial mask to be refined to the nano-level. This ultra-fine refinement not only greatly improves the absorption efficiency of the skin, but also guarantees that the nutrients can penetrate into the bottom layer of the skin and play a better role in nourishing and repairing. In addition, the introduction of intelligent materials has brought revolutionary improvement to the use experience of the facial masks. By intelligently adjusting the temperature of the facial mask, it can always maintain the most suitable temperature for the skin during use, thus further enhancing the comfort and effect of use. The application of these technologies not only reflects the profound strength of this project in technology research and development, but also lays a solid foundation for the market competitiveness and long-term development of the project.

Cold compress is a common first-aid item, and is usually used for emergency treatment such as relieving pain, reducing swelling, and stopping bleeding, etc; It can also be used for beauty and skincare, and has a good effect in relieving eye fatigue, and reducing dark circles, etc. The following is the production process of cold compress.

1. Preparation of raw materials

The main raw materials of cold compress include non-woven fabrics, transparent adhesive tapes, water and liquid gel, etc. Before production, it is necessary to inspect the raw materials to guarantee that they are qualified. Non-woven fabrics and transparent adhesive tapes need to be cut, and the size shall be adjusted according to the size of the required products.

2. Preparation of liquid gel

Liquid gel is an important part of the cold compress, and it is generally composed of many ingredients such as moisturizing agent, thickening agent, and antibacterial agent, etc. It is made by adding the raw materials of liquid gel into the mixer in a certain proportion, mixing them evenly, and then undergoing high-temperature sterilization, filling and other processes.

3. Printing

Cold compress is usually printed on non-woven fabrics to enhance its aesthetic appeal and brand image. Printing adopts silk-screen printing or flexographic printing, where the pattern to be printed is firstly made into a printing plate or silk-screen template, and then ink is applied to non-woven fabrics.

4. Stereotyping

The non-woven fabrics after printing need to undergo stereotyping treatment to guarantee that its shape remains unchanged. The stereotyping process is carried out by high-temperature baking, where the printed non-woven fabric is placed in a stereotyping oven and heated for a certain period of time to make it hard.

5. Plastic sealing

Non-woven fabric and transparent adhesive tape need to undergo plastic sealing to maintain the cleanliness and moisture resistance of the cold compress. Plastic sealing is achieved by heating non-woven fabric and transparent adhesive tape together in a heat-sealing machine to bond them together.

6. Cutting

After plastic sealing treatment, there will be a large piece of cold compress, which shall be cut into the required size. The cutting may be performed using either a die-cutting machine or a cutting-knife machine, which shall be selected depending on the product specifications.

7. Packaging

After the production of cold compress is completed, they need to be packaged for storage and sale. Common packaging methods include: individual packaging, multi-piece packaging, and boxed packaging, etc. Packaging is generally done using plastic bags, paper boxes, and outer packaging, etc.

8. Quality inspection

It needs to make quality inspection during the production process to guarantee that the product meets relevant standards and regulations. It mainly includes appearance inspection, dimension inspection, and liquid gel inspection, etc. Only the products that meet quality requirements can proceed to the next stage of packaging and sales.

1.1.4 Advantageous conditions of project construction

(1) Policy advantages

In the 14th Five-year Plan for Bioeconomy Development by the National Development and Reform Commission, it was mentioned that we should focus on drugs, vaccines, advanced diagnostic and treatment technologies and equipment, biomedical materials, precision medicine, inspection and testing, biological health and rehabilitation and other directions to enhance the original innovation capability and strengthen scientific research on drug regulation; With the goal of promoting breakthroughs in key technologies and the transformation and application of scientific and technological achievements, we should support the leading enterprises to take the lead in forming innovation consortia, undertake the construction of innovation platforms such as industrial innovation centers, engineering research centers, technology innovation centers, and manufacturing innovation centers, etc., encourage innovation and entrepreneurship in the field of biotechnology, and support the development of small and medium-sized enterprises.

In the Implementation Plan for Promoting the High-quality Development of Biomedical and High-performance Medical Device Industry in Jilin Province, it was mentioned that we should accelerate the development of medical devices. We should give full play to the research and development advantages of institutions such as the Changchun Institute of Optics, Fine Mechanics and Physics, Changchun Institute of Optics, and Jilin University, etc. in the fields of optoelectronic technology, medical implant materials, and molecular diagnostics, etc., with a focus on the research and development and industrialization of strongly innovative and high-value optoelectronic technology, absorbable implantable medical devices, in vitro diagnostic instrument, and matching reagent products.

(2) Talent advantages

Changchun is a well-known high intelligence intensive area in China, with more than ten key universities such as Jilin University, Northeast Normal University, and Changchun University of Science and Technology. It also has national and provincial (ministerial) scientific research institutions such as the Chinese Academy of Sciences, Changchun Branch, Changchun Institute of Optics, Fine Mechanics and Physics, Changchun Institute of Applied Chemistry, as well as scientific research institutions such as design institutes, computing and testing centers, and several key national open laboratories in Changchun. Changchun City has abundant human resources and price advantages. Higher education institutions and research institutions such as Jilin University, Northeast Normal University, Changchun University of Traditional Chinese Medicine, Changchun Institute of Optics, Fine Mechanics and Physics, and Changchun Institute of Applied Chemistry can provide senior management and technical personnel for the implementation of the project.

(3) Location advantages

The Nong’an Economic Development Zone is located on an important node of the Harbin-Changchun Megalopolis, it is the core area of Changchun’s half-hour economic circle, as well as the main channel for entry from the south and exit from the north. The development zone borders Changchun New District to the east and Kuancheng District and Lvyuan District to the south. Kaixuan Road and Qingnian Road extend to the town area, and there are four bus routes within the city that have access to the town. In addition, it is 680 kilometers away from Dalian Port, 58 kilometers away from Longjia International Airport, and 20 kilometers away from Changchun Land Port. There are transportation arteries such as G12, G302, S106 and the Changchun-Baicheng Railway, etc. running through the territory, having formed a three-dimensional transportation system surrounded by highways, expressways, and rail transit.

1.2 Contents and scale of project construction

1.2.1 Product scale of the project

After the project is put into production, the annual production scale of medical facial mask cold compress will be 5 million.

1.2.2 Contents of project construction

The project covers a total area of 30,000 square meters, with construction of new medical facial mask cold compress production workshop, purchase of 300 sets of new equipment, as well as construction of constant-temperature warehouse center, technology research and development laboratory, training center, staff dormitory and other supporting facilities.

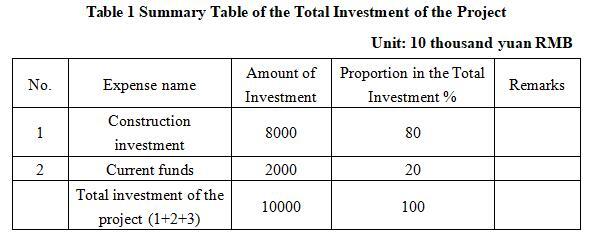

1.3 Total investment of the project and capital raising

1.4 Financial analysis and social evaluation

1.4.1 Main financial indexes

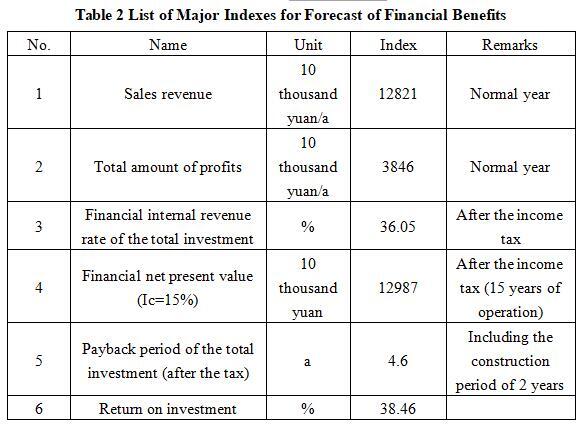

After the project reaches the production capacity, its annual sales income will be 128.21 million yuan, its profit will be 38.46 million yuan, its investment payback period will be 4.6 years (after the tax, including the construction period of 2 years), and its return on investment will be 38.46%.

Note: “10 thousand yuan” in the table is in RMB

1.4.2 Social evaluation

Implementing this project can provide a large number of job opportunities for the society, thereby helping to alleviate the employment pressure and provide job opportunities for more people. Meanwhile, the construction of the project will directly create significant economic value and contribute to the economic development of the region and even the country. In addition, the project will promote the aggregation of related industries, form an industrial chain, enhance the synergistic effect of the industries, and further promote the prosperity and development of the entire industry. Meanwhile, the project will continuously promote technological innovation during implementation, adopt advanced technology and management methods, improve production efficiency and product quality, and set new benchmarks for the industry. Due to these positive impacts, there is a very positive evaluation of the project in the society, and it is widely believed that it will bring long-term benefits to the society.

1.5 Project cooperation way

Joint venture, and other ways can be discussed in person.

1.6 What to be invested by the foreign party

Capital.

1.7 Construction site of the project

Nong’an Industrial Concentration Zone Management Committee

1.8 Progress of the project

The project is in planning phase

2. Introduction to the Partner

2.1 Basic information

Unit: Nong’an County Economic Cooperation Promotion Center

Address: Xinghua Road, Nong'an Town, Nong’an County, Jilin Province

2.2 Overview

Nong’an County is located in the hinterland of the Songliao Plain in the middle part of Jilin Province, covering an area of 5,400 square kilometers. It has jurisdiction over 22 townships, 4 sub-districts, and 377 villages, with a total population of 1.2 million. Nong’an County has 382,804 hectares of arable land and 353,782 hectares of basic farmland, making it the county with the largest arable land area and the largest population in Jilin Province.

Nong’an County is located in the core area of one of the world’s three largest golden corn belts, with abundant rainfall, fertile soil, sufficient sunshine, distinct four seasons, an average annual temperature of 4.7℃, a frost-free period of 145 days, an annual precipitation amount of 507.7 millimeters, and an effective accumulated temperature of 2,800℃. It is a “national-level” agricultural and pastoral county. Songhua River, Yitong River and Xinkai River pass through the county. The water area of the county is 22,000 hectares, with an average annual total water resources of 630 million cubic meters, including exploitable underground water of 310 million cubic meters, and daily natural mineral water inflow of 2,000 tons; There are 4 large and medium-sized reservoirs and 2 large wetlands (Shallow Basket Lake is a national wetland nature reserve, and Taipingchi Reservoir has been approved as a national wetland park). The proven industrial reserves of oil shale within the country are 38 billion tons; The industrial reserves of clay are 10 million tons, containing over 20% aluminum oxide (Al2O3); Proven industry reserves of natural gas are 760 billion cubic meters; The industrial reserves of carbon dioxide (CO2) gas are 9 billion cubic meters. It is rated as a National Ecological Construction Demonstration Zone, Top 100 Chinese New Energy Industry Counties, China Low-carbon Economy Demonstration County, and National Green Energy Demonstration County.

The county town is 60 kilometers away from Changchun City, and is located within the half-hour economic circle of Changchun. It is 110 kilometers away from Changchun Longjia Airport, and 700 kilometers away from Dalian Port; The Changchun-Baicheng Railway, G12 Expressway, C334 National Highway, and G302 National Highway run north-south within the county. The two trunk roads in Changchun, i.e., Kaixuan Road and Qingnian Road, have been extended to Nong’an, forming a strategic open pattern based in Changchun, connecting the surrounding areas, and linking with the Northeast China. As the first county in Changchun to have established a national-level health county, Nong’an County is a pilot county for “Empowering county rights for prosperity” in the province. It has successively won honors such as the China Top 100 County-level Investment Potential Counties, China County with the Most Investment and Business Value, National Social Governance Innovation Model County, and China Top 100 Counties with the Greatest Sense of Security, etc.

Changchun Nong’an Economic Development Zone Equipment Industrial Park focuses on the development of automobile equipment, mechanical processing, and passenger car supporting industries, etc., promoting the clustering of enterprises in the industrial park to play industrial agglomeration effect and driving radiation effect. It focuses on standardization of automobile and passenger car parts, the provision of big data, and communication technology, to promote the intelligence, personalization, networking, and service of the manufacturing industry.

2.3 Contact method

2.3.1 Contact method of cooperator

Contact unit: Nong’an County Economic Cooperation Promotion Center

Contact address: Xinghua Road, Nong’an Town, Nong’an County, Jilin Province

Tel: +86-431-89936018

2.3.2 Contact method of the city (prefecture) where the project is located:

Contact unit: Changchun Cooperation and Exchange Office

Contact person: Zhang Junjie

Tel: +86-15704317930

Fax: +86-431-82700590

E-mail: xmc82763933@163.com