Modern Service Industry

Express logistics Intelligent Distribution Center Construction Project of Siping City

1. Introduction to the Project

1.1 Project background

1.1.1 Product introduction

In the process of accelerating e-commerce logistics, sorting is a very important link. The traditional sorting method for express delivery generally involves mixing large and small items on a conveyor belt for sorting. The “intelligent sorting cabinet for express delivery” implements the separation of large and small goods to avoid damage to small goods caused by the mixing of large and small items, while reducing problems such as small goods getting stuck in the conveyor belt. At the same time, this intelligent device does not require manual memory of the destination station, achieving “brainless” sorting operations and greatly improving sorting efficiency. During the process of sorting personnel delivering parcels, the equipment will also provide prompts by lighting up, greatly reducing the rate of parcel mis-classification caused by mis-operation.

This product is located in Shuangliao City and aims to build an efficient, intelligent, and environmentally friendly logistics and express distribution center. Through the combination of manual and intelligent system technology, it realizes the distribution and transportation of local express packages and the delivery of rural agricultural e-commerce packages, providing various logistics enterprises with automated, information-based, and personalized professional warehousing services.

1.1.2 Market prospect

(1) The current development status of the automatic sorting industry

2023 is both a year full of opportunities and a year facing challenges for China’s intelligent logistics equipment market. With this, the logistics equipment industry has also entered a new stage of development. According to statistics, the scale of China’s intelligent logistics equipment market reached 100.39 billion yuan in 2023, an increase of about 21% compared to the previous year. Meanwhile, the complex macroeconomic environment has had multiple impacts on the automatic sorting market, posing new challenges for the development of enterprises. According to data, the market size of automatic sorting equipment in China reached approximately 32 billion yuan in 2023, with an annual growth rate of 10.3%.

The demand for automatic sorting equipment for express delivery is closely related to the quantity of express packages in China, as well as the amount of online shopping by consumers. From the perspective of consumer habits, there is still room for improvement in the penetration rate of Chinese e-commerce. According to statistics from the State Post Bureau, the cumulative volume of postal delivery services in China’s postal industry reached 162.48 billion in 2023, a year-on-year increase of 16.8%. Among them, the total volume of express delivery services (excluding postal group parcel services) reached 132.07 billion, a year-on-year increase of 19.4%. The cumulative revenue of express delivery business reached 1207.40 billion yuan, a year-on-year increase of 14.3%. The continuous growth in the number of express packages indicates that the development potential of automatic sorting equipment in the express delivery industry is still enormous.

As of the first half of 2023, the number of self-operated hub transfer centers in Zhongtong, Yuantong, Yunda, and Shentong is 87, 70, 75, and 70, respectively. Yunda’s hub transfer center has a direct operation rate of 100%, while Zhongtong’s rate is 91%. Yuantong and Shentong have already achieved a high degree of direct operation. After the self operation of the transfer center, the express headquarters, based on its own financial advantages and the need to reduce operating costs, has a strong desire for automation transformation of the transfer center to effectively improve its operational efficiency.

Overall, the automatic sorting industry has entered a cyclical adjustment period after experiencing rapid development. Industry enterprises are beginning to focus on lean production and management, honing their internal skills, and seeking their own unique tracks for differentiated development, in order to prepare for the next growth cycle.

(2) Prospect analysis of the automatic sorting industry

In the past two years, the field of conveying and sorting has undergone significant changes and upgrades, and the trend of transformation is very obvious. With the rise of new economic models such as e-commerce and new retail, customers’ expectations for logistics services are constantly increasing, and logistics services are gradually moving towards intelligence and intelligence. The market demand for high efficiency, flexibility, and reliability will further increase. The demand characteristics of the conveying and sorting industry can be summarized as follows:

Due to the significant differences in demand for automatic sorting equipment among different industries, future automatic sorting systems will develop towards more detailed directions based on customer needs and changes in business models. This includes two categories of small and large item sorting, and is developing towards two directions: automated sorting systems dominated by traditional conveyor sorting equipment and flexible sorting systems dominated by intelligent AGVs and robotic equipment.

With the decline of the demographic dividend and the increase in labor costs, various industries are gradually transitioning towards unmanned operations. The continuous advancement of emerging technologies such as artificial intelligence, robotics, wireless communication, big data cloud platforms, humanoid simulation, sensing technology, micro control technology, and 5G has given rise to the emergence of black light factories and unmanned warehouses. Breakthroughs in technologies such as automatic loading and unloading, multi piece separation, bagging and changing bags, automatic recognition of six sided high-speed item information, and supercapacitors, combined with low power consumption and maintenance free technology, have led to the overall development of unmanned warehouse distribution centers/sorting centers, including automatic sorting systems.

The continuous advancement of machine vision recognition, information technology, and deep learning technology has made it possible to intelligently and efficiently collect logistics system data, thereby achieving high-speed intelligent sorting. The emergence of cloud platform has promoted the development of big data, provided a foundation for “Internet+”, “smart+” and deep machine learning, significantly improved the operating efficiency of equipment, and laid a foundation for intelligent equipment. At the same time, the development of the Internet of Things and 5G technology has enabled remote monitoring and maintenance of logistics equipment systems, significantly improving the availability, utilization, and operational efficiency of automatic conveyor sorting systems.

After years of growth, especially after several express delivery companies went public in 2016, the automatic sorting industry has rapidly undergone automation upgrading, and the automatic sorting system equipment has accumulated a considerable stock market. According to preliminary statistics, the inventory of domestic cross belt sorting equipment has exceeded 4000 sets, some of which have exceeded their warranty period. With the continuous expansion of business scale, the demand for automatic sorting technology by express delivery companies has undergone significant changes since 2022, with an increase in the number of after-sales maintenance, equipment upgrades, relocation, and renovation projects. In 2023, the demand for aftermarket services will further increase, providing customers with after-sales service guarantees and creating new profit growth points through the aftermarket. The market prospect is very broad. In February, 2022, Qingpu Roundtable Conference was initiated, with the participation of major domestic manufacturers of automatic sorting equipment. Shanghai Duliangxing Equipment Installation and Maintenance Co., Ltd. was established, focusing on the post market service field and providing support for the development of the automatic sorting industry chain. At the same time, Qingpu Roundtable Conference cooperated with SGS to conduct group standard certification for the automatic sorting industry, and Jinfeng Group became the first enterprise to obtain SGS group standard certification qualification.

After nearly 7 years of rapid development, the express delivery industry has established a complete network of large-scale distribution centers with strong transit and distribution capabilities. However, the operational efficiency of end of pipe branches has become the main bottleneck for the “last kilometer” of express delivery services. With the increasing demand of consumers for the timeliness of express delivery, express delivery companies will also actively improve the automation level of their end outlets to comprehensively enhance their service level and overall competitiveness. In addition, starting from 2022, mature logistics automation technology will gradually “sink” to county, township, and even village level express delivery outlets with the promotion of the strategy of “express delivery to villages”, realizing the automation of branch operations and meeting the logistics and supply chain needs of rural areas.

With the rapid development of logistics, e-commerce, and manufacturing, the market prospect of the automatic sorting industry is very broad. With the booming development of global e-commerce, online shopping has become a part of people’s daily lives, which directly drives the demand for efficient and accurate automatic sorting systems. These systems are capable of handling massive orders, ensuring that goods can be quickly and accurately delivered to consumers. In addition, with the automation and intelligent transformation of the manufacturing industry, automatic sorting technology is playing an increasingly important role on the production line. It not only improves production efficiency, but also reduces labor costs and error rates. In this context, the automatic sorting industry is facing unprecedented development opportunities. It is expected that in the next few years, with the continuous progress of technology and the expansion of application fields, the industry will present a more prosperous scene.

1.1.3 Advantageous conditions of project construction

(1) Policy conditions

The Notice on Doing a Good Job in the Key Work of Cost Reduction in 2024 mentions the improvement of the modern logistics system. Steadily promote the construction of national logistics hubs and national backbone cold chain logistics bases, and promote the high-quality development of modern logistics. Add support for a group of cities to carry out national comprehensive freight hub chain supplementation and strengthening, promoting the integration of cross transportation modes. Continue to implement county-level commercial construction actions, support the construction and renovation of county-level logistics distribution centers and township express logistics stations, improve warehousing, transportation, distribution and other facilities, accelerate the filling of rural commercial facility shortcomings, and improve the county-level and rural logistics distribution system.

The Three-Year Action Plan for Data Element X (2024-2026) points out to promote internationalization, encourage e-commerce enterprises, modern circulation enterprises, and digital trade leading enterprises to integrate transaction, logistics, and payment data under the premise of security and compliance, and support the improvement of supply chain integrated services, cross-border identity authentication, global supply chain financing, and other capabilities.

(2) Project advantages

Relying on silica sand resources, the two major glass giants in China, Jinken Glass Co., Ltd. and Yingxin Glass Co., Ltd., have gathered in Shuangliao, becoming the only glass building materials characteristic park in Jilin Province, the largest glass building materials base in northern China, and a nationally planned northern siliceous raw material production base. Shuangliao is located in the world’s “Golden Corn Belt”, with a total cultivated land area of 2.8 million mu and a stable annual grain production of 3 billion jin. It is the largest livestock distribution center in Jilin Province, Liaoning Province, and Inner Mongolia. It has been successively named as a national grain producing county, a national commodity grain base county, a national sheep base county, a national lean meat pig base county, and a national ecological demonstration county.

During the 14th Five-Year Plan, Shuangliao City will make every effort to build a billion yuan level logistics base that radiates to Mongolia, Jilin, Heilongjiang, and Liaoning, and accelerate the construction of a provincial-level logistics layout city. Taking the logistics park as a platform, it vigorously develops smart logistics, bonded logistics, and cold chain logistics, and strives to build Shuangliao into a commodity gathering and distribution base serving the economic development of Northeast China, as well as a gathering center for logistics, passenger flow, information flow and other elements.

(3) Location advantages

Shuangliao has significant location advantages, located in the central area of Liaoning, Jilin, and eastern Inner Mongolia. In the Central Urban Agglomeration Plan of Jilin Province, Shuangliao has been positioned as the central city and gateway city of western Jilin Province. Shuangliao is a transportation hub in the western part of Northeast China and an important material distribution center in the region.

There are two railways passing through the area: Shuangliao to Dahushan and Siping to Qiqihar; Daqing to Guangzhou, Changchun to Shenzhen, Ji’an to Xilinhot, Nenjiang to Dandong, Shuangliao to Baicheng and other highways intersect in Shuangliao, making it the only city in Jilin Province with multiple highway nodes and 9 highway exits; there are two national trunk highways from Shenyang to Mingshui and from Ji’an to Xilinhot, with G231 Nenjiang-Shuangliao Railway running through the north and south; the provincial trunk road from Changchun to Shuangliao spans from east to west. Shuangliao is a 50 minute drive from Tongliao Airport, and a 150 minute drive from Changchun Longjia International Airport and Shenyang Taoxian International Airport. Shuangliao will integrate into the 1-hour economic circle of Changchun and the 2-hour economic circle of Shenyang.

1.2 Contents and scale of project construction

The total land area of the project is 58000 square meters, mainly consisting of five areas: intelligent warehousing area, robot sorting area, automated packaging area, distribution area, and comprehensive service center.

1.3 Total investment of the project and capital raising

1.3.1 Total investment of the project

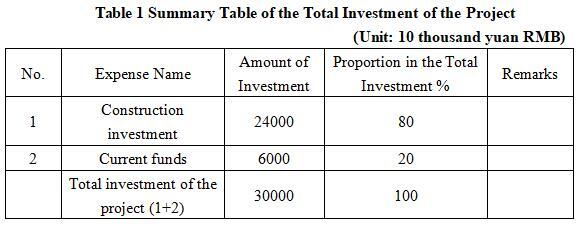

The total investment of the project is 300 million yuan, including the construction investment of 240 million yuan.

1.4 Financial analysis and social evaluation

1.4.1 Main financial indexes

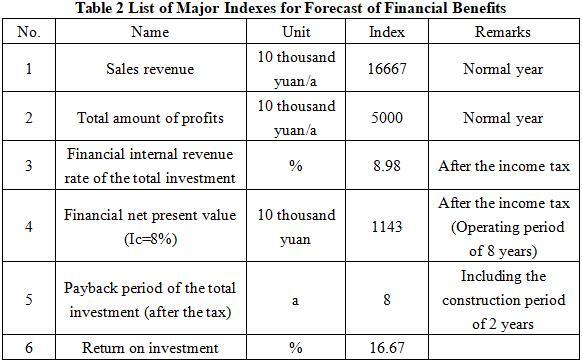

After the project reaches the production capacity, its annual sales revenue will be 166.67 million yuan, its profit will be 50 million yuan, its investment payback period will be 8 years (after the tax, including the construction period of 2 years) and its return on investment will be 16.67%.

Note: “10 thousand yuan” in the table is in RMB.

1.4.2 Social evaluation

In terms of social evaluation, the intelligent distribution center project for express logistics has received high praise. This project has significantly improved logistics efficiency, shortened delivery time, and made significant contributions in the fields of environmental protection and sustainable development. By applying advanced automation technology, the speed and accuracy of parcel sorting have been significantly improved, thus winning widespread recognition from the industry and consumers. The construction of intelligent distribution centers not only creates numerous employment opportunities for the local society, but also promotes the development of related industrial chains, thereby driving regional economic growth. In addition, the project has shown outstanding performance in energy conservation and emission reduction, effectively reducing carbon emissions by optimizing transportation routes and adopting clean energy, setting an example for environmental protection. Community residents hold a positive attitude towards the implementation of this project, as it not only improves the quality of logistics services, but also has a positive impact on their daily lives.

1.5 Cooperative way

Joint venture or cooperation

1.6 What to be invested by the foreign party

Funds, and other methods can be discussed in person.

1.7 Construction site of the project

Shuangliao City

1.8 Progress of the project

The project is in the planning phase.

2. Introduction to the Partner

2.1 Basic information

Name: Shuangliao Municipal People’s Government

Address: 1980 Liaohe Road, Shuangliao City, Siping City

2.2 Overview

Shuangliao City is located at the junction of Jilin Province, Liaoning Province, and Inner Mongolia, adjacent to the Songliao Plain and the Khorqin Grassland, and is known as the place where “chicken crowing is heard in three provinces”. The jurisdiction covers an area of 3121.2 square kilometers, with a permanent population of 320000. It has jurisdiction over 18 townships (streets) and 1 provincial-level economic development zone. There are 2 railways and 4 national and provincial trunk lines within the territory, making it the only node city in Jilin Province with 4 highways and 9 highway exits.

Shuangliao City, with the advantages of the “backyard” and “natural oxygen bar” in western Jilin Province, has integrated local characteristic cultures such as fishing and hunting culture, nomadic culture, agricultural culture, red culture, religious culture, and industrial culture into the construction of scenic spots, urban development, supporting facilities, and commodity development, and built a green ecological barrier in western Jilin. According to the overall plan for the development of comprehensive tourism in Shuangliao City, relying on the existing water system, wetlands, and grassland resources, two corridor style tourism belts will be formed, namely, the “Ecological Experience Tourism Belt” and the “Rural Leisure Tourism Belt”.

The booming tourism economy in Shuangliao City has created a green channel for two-way communication between urban and rural areas, online and offline, and physical and online. With the help of this new sales channel, the development of the ice and snow cultural tourism industry also needs to find a suitable “traffic entrance”, form an effective connection and undertaking platform, and stimulate more ice and snow cultural tourism products and services, becoming a dominant market entity in the industry chain.

2.3 Contact method

2.3.1 Contact method of the partner

Contact person: Huang Xibo

Tel: +86-13844438112

2.3.2 Contact method of the city (prefecture) where the project is located

Contact unit: Siping Bureau of Economic Cooperation

Contact person: Wen Dacheng

Tel: +86-434-3260536

E-mail: spjhjjhk@163.com