New Material

Polylactic Acid Project of Changchun City

1. Introduction to the Project

1.1 Project background

1.1.1 Project introduction

Polylactic acid has good thermal stability, processing temperature of 170~230°C, good solvent resistance, and can be processed in a variety of ways, such as extrusion, spinning, biaxial stretching, injection blow molding. In addition to being biodegradable, products made of polylactic acid have good biocompatibility, gloss, transparency, hand feel and heat resistance.

Polylactic acid (PLA) is a new type of biodegradable material made from starch raw materials derived from renewable plant resources such as corn. Starch raw materials are saccharified to obtain glucose, and then fermented by glucose and certain strains to produce high-purity lactic acid, and then synthesized polylactic acid with a certain molecular weight through chemical synthesis. It has good biodegradability, can be completely degraded by microorganisms in nature after use, and finally generates carbon dioxide and water without polluting the environment, which is very beneficial to the protection of the environment, and is recognized as an environmentally friendly material.

1.1.2 Market prospect

(1) Plastic pollution hazards

With the development of the economy, consumption upgrading, and the rapid development of the express delivery industry and takeaway industries, plastics have become a necessity in our daily life, such as express packaging, takeaway packaging boxes, supermarket shopping bags, etc. In recent years, the consumption of plastics has been increasing, and the environmental pollution problem has become increasingly apparent, which has brought great harm to human health and the ecological environment. Currently, the main problem of environmental pollution is the decomposition of plastics, such as microplastics and chemical additives, many of which are known to be toxic and harmful to the health of humans and wildlife, as well as to ecosystems. The human body is susceptible to plastic contamination of water sources in several ways, which can lead to hormonal changes, developmental disorders, reproductive abnormalities, and cancer. Plastics are ingested through seafood, beverages, and even table salt; when plastics are suspended in the air, they are inhaled and penetrate the skin.

The treatment of plastic pollution should mainly start from four aspects: source reduction, recycling, substitution and cleanup, among which replacing traditional plastics with degradable plastics in the natural environment is an important part of the above treatment work. At present, countries around the world have introduced policies to encourage the use of degradable plastics, and China has also introduced a new version of the plastic ban in 2020 to support the promotion and use of degradable plastics.

According to incomplete statistics, at present, the European Union, North America, Japan, South Korea, Thailand, Pakistan and some countries in Africa have issued different degrees of plastic bans or plastic restrictions, and the data of some countries show that the use of disposable plastic products has declined. Countries around the world have accelerated plastic bans and restrictions.

(2) Application prospect of polylactic acid degradable materials

From the perspective of actual demand, with the support of the plastic restriction and plastic ban regulations of various national and regional governments, the actual global demand for degradable plastics has maintained a continuous growth trend. In terms of downstream applications, polylactic acid has been applied in many fields due to its unique biocompatibility and biodegradability, and the application scenarios are constantly expanding. At present, it has been widely used in food contact packaging and tableware, film bag packaging and other products and fields. For example, the agricultural mulch film made of polylactic acid can completely degrade and disappear after the crop is harvested, which will not reduce the moisture content and fertility of the soil, and can also exempt the additional labor and operation costs required to recycle the mulch film, which is the general trend of China's future plastic film development, and the future development space of the polylactic acid industry is huge.

In recent years, the market size of China's takeaway catering has developed rapidly, and the market size of China's takeaway industry was about 1,525.4 billion yuan in 2024, and it is expected to maintain a strong growth momentum in the next few years, and is expected to reach 1,956.7 billion yuan by 2027. Takeaway requires the consumption of a large number of plastic products, including plastic lunch boxes, plastic bowls, plastic soup spoons, plastic straws, etc. In addition, the “Opinions on Further Strengthening the Control of Plastic Pollution” issued by the state clearly mentions the orderly prohibition and restriction of the production, sale and use of non-degradable plastic bags and non-degradable disposable plastic tableware, and the active promotion of alternative products. It can be expected that the plastic products used in takeaway will be gradually replaced with degradable plastic products, so that the demand for polylactic acid will continue to increase.

Analysis of the market size of polylactic acid, from the perspective of the application field of polylactic acid, packaging materials are currently the largest consumer area, accounting for more than 65% of the total consumption. With the improvement of environmental awareness and the requirements of sustainable development, the application of polylactic acid in the packaging field is expected to further expand. At the same time, applications such as catering utensils, fiber/non-woven fabrics, and 3D printing materials also provide new growth points for the polylactic acid market. As a biodegradable material, polylactic acid has a good market development prospect, especially driven by factors such as environmental awareness improvement, technological improvement and policy support, the polylactic acid market is expected to usher in more development opportunities.

1.1.3 Technical analysis

Polylactic acid production is based on lactic acid as raw material, and most of the traditional lactic acid fermentation with starchy raw materials. At present, the United States, France, Japan and other countries have developed the use of agricultural and sideline products as raw materials to ferment lactic acid to produce lactic acid, and then produce polylactic acid. The preparation of polylactic acid can be divided into the following three methods.

1. Direct polycondensation method

The polycondensation method is the direct condensation of lactic acid monomers, also known as one-step polymerization. In the presence of a dehydrating agent, the hydroxyl and carboxyl groups in the lactic acid molecule are dehydrated by heat and directly condensed into oligomers. A catalyst is added, the temperature continues to rise, and the low relative molecular weight polylactic acid polymerizes into a higher relative molecular weight polylactic acid.

2. Two-step method

Lactic acid is used to form cyclic dimeric lactide, which is then opened and polycondensed into polylactic acid. This technology is relatively mature, and the main process is that the raw materials are fermented by microorganisms to obtain lactic acid, and then after refining, dehydration oligomerization, high-temperature cracking, it is finally polymerized into polylactic acid.

3. Reaction extrusion to prepare high molecular weight polylactic acid

The combination of batch stirring reactor and twin-screw extruder was used to carry out continuous melt polymerization experiments. Polylactic acid with a molecular weight of 150,000 can be obtained by continuous melt polycondensation. A twin-screw extruder is used to further polycondense the low molar mass of lactic acid prepolymer on the extruder to prepare a higher molar mass of polylactic acid. When the reaction temperature is 150°C, the catalyst dosage is 0.5%, and the screw speed is 75 r/min, the molar mass of polylactic acid can be quickly and effectively improved by twin-screw reaction extrusion polycondensation, and the dispersion coefficient of the reaction extrusion product is reduced and the uniformity is improved. Through the comparison of DSC curves, it was found that the crystallinity of polylactic acid prepared by reactive extrusion polycondensation method was reduced, which was beneficial to improve the brittleness of polylactic acid materials during use.

The project partner company, Donghua Tianye (a subsidiary of Donghua Technology Holdings), is vigorously expanding the industrial chain of degradable materials, is developing the production process of polylactic acid (PLA), and has overcome the production technology of PLA lactide products.

1.1.4 Advantageous conditions of project construction

(1) Policy advantages

The National Development and Reform Commission and the Ministry of Ecology and Environment (MEE) issued the “Opinions on Further Strengthening the Control of Plastic Pollution”, which proposes: The production, sale and use of non-degradable plastic bags, non-degradable disposable plastic tableware, hotels, hotel disposable plastic supplies and express plastic packaging shall be prohibited and restricted in an orderly manner, and alternative products shall be actively promoted. The promulgation of this regulation has clarified the specific timetable of “plastic restriction and ban”, which has played a great role in promoting the application of polylactic acid products in China.

The introduction of policies such as “Opinions on Accelerating the Prevention and Control of Agricultural Mulch Film Pollution”, “14th Five-Year Plan” for the Development of Circular Economy”, “Standard Conditions for Agricultural Film Industry (2017) ”, and “Classification of Strategic Emerging Industries (2018) ” have also brought market demand to polylactic acid. This is mainly due to the above-mentioned policies' strict constraints on the production and circulation and scale of agricultural mulch film and the, put forward higher requirements for the recycling level of traditional non-degradable agricultural film, and encourage enterprises to develop, produce and promote biodegradable agricultural film and other green products.

(2) Talent advantages

Changchun is a city located in a university, with 15 national key laboratories, 83 independent scientific research institutions in Changchun, such as the Changchun Institute of Optics, Fine Mechanics and Physics of the Chinese Academy of Sciences, the Institute of Applied Chemistry of the Chinese Academy of Sciences, and the Institute of Geographic Sciences and Natural Resources Research of the Chinese Academy of Sciences, and 49 colleges and universities such as Jilin University and Northeast Normal University, which can provide senior managers and technicians for the implementation of the project.

(3) Location advantages

Changchun New Area Fine Chemical Industrial Park is located in Changchun New Area, which is located in the geographical center of Northeast China and the core hinterland of Changchun-Jilin-Tumen Pilot Zone as a whole, and is an important node of the Harbin-Dalian Economic Belt and the China-Mongolia-Russia Economic Corridor. The park has a convenient transportation network, including air, rail, high-speed and light rail. In particular, Longjia International Airport, known as the “Northeast Asian air transportation hub”, enable people to reach 2/3 of China's cities in 1.5 hours and fly to major cities around the world in 5 hours.

(4) Advantages of the park

Changchun Fine Chemical New Material Industrial Park, relying on the National Sciences Institute of Innovation, the Institute of Applied Chemistry of the Chinese Academy of Sciences, Jilin University and leading enterprises in the domestic chemical industry, focuses on the development of high-performance luminescent materials, functional polymer materials, special fibers and their reinforced composite materials, chemical special additives, chemical raw materials and preparations, etc., and strives to build a new material industry development highland based in Jilin and radiating to Northeast China.

(5) Industrial advantages

At present, there are 104 new energy and new material enterprises, including 20 enterprises above the designated size, and their products include biomass materials, chemical raw materials manufacturing, pharmaceutical intermediates and other fields, with an output value of nearly 5 billion yuan. With a total investment of 17.5 billion yuan, the fine chemical new materials industrial park was started and constructed, which is the only chemical park in Changchun City that has passed the new certification, and is also a key project in Jilin Province to promote the development of the petrochemical industry during the “14th Five-Year Plan”, aiming to build a standardized factory area of high-quality “chemical APIs and preparations” and “application-oriented new materials”.

1.2 Contents and scale of project construction

With an area of 50,000 square meters and a raw material processing area, the project is planned to build a storage area, a product processing area, and a packaging area, equipped with fermenters, polymerization reactors, melting equipment, extruders, waste gas treatment, wastewater treatment and solid waste treatment systems.

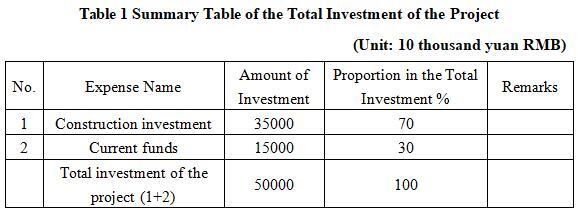

1.3. Total investment of the project and capital raising

The total investment of the project is 500 million yuan, including the construction investment of 350 million yuan

1.4 Financial analysis and social evaluation

1.4.1 Main financial indexes

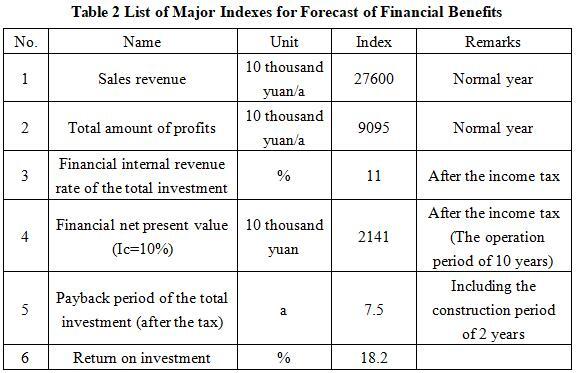

After the project reaches the production capacity, its annual sales income will be 276 million yuan, its profit will be 90.95 million yuan, its investment payback period will be 7.5 years (after the tax, including the construction period of 2 years) and its investment profit rate will be 18.2%.

Note: “10 thousand yuan” in the table is in RMB.

1.4.2 Social evaluation

After the completion of this project, it will be conducive to increasing the production capacity of polylactic acid material products, and strengthening the construction of supporting infrastructure, which will play a positive role in promoting the development of regional economy, increasing fiscal revenue, driving the development of local related industries and solving labor employment.

1.5 Cooperative way

Sole proprietorship, joint venture and cooperation, etc.

1.6 What to be invested by the foreign party

Funds and other ways can be negotiated face to face.

1.7 Construction site of the project

Changchun New Area Fine Chemical Industrial Park

1.8 Progress of the project

Project proposal has been prepared

2. Introduction to the Partner

2.1 Unit basic information

Name: Changchun New Area Management Committee

Address: No. 5799, Longhu Road, Beihu Science and Technology Development Zone, Changchun City

2.2 Unit overview

Changchun Beihu Fine Chemical New Materials Industry Demonstration Park was approved by the Jilin Provincial Government on April 30, 2021, and is the only chemical park in Changchun City that has passed the new certification, and it is also a key project in Jilin Province to promote the high-quality development of the petrochemical industry in the “14th Five-Year Plan”, which plays an important role in promoting the development of biomedicine, new materials, fine chemicals and other industries in the province and cities and Changchun New Area. The total investment of the park is about 11 billion yuan, and the planned area is 9 square kilometers. The planned construction land area of the first phase is 3.698 square kilometers; the planned construction land of the second phase covers an area of 5.3 square kilometers, and as an expansion area for the development of the future chemical park, the overall plan has been implemented simultaneously.

In accordance with the principle of “scientific planning, industrial agglomeration, spatial layout optimization, and sustainable development”, the park will focus on the development of four functional industrial parks, including special chemicals, synthetic materials, chemical raw materials and chemical preparations. Among them, the synthetic material manufacturing park mainly develops high-performance luminescent materials, high-performance composite fiber materials, high-performance engineering plastics, high-performance membrane materials, medical high-value consumables, high-performance adsorption materials, etc.; The special chemicals manufacturing park mainly develops high-performance environmental protection catalysts, functional composite additives, automotive environmental protection adhesives, electronic adhesives, functional compound surfactants, green multi-functional water treatment agents, new energy vehicle battery materials, etc.; The chemical API manufacturing park mainly develops biological reagent raw materials, characteristic APIs, patented APIs, pharmaceutical intermediates, tissue engineering materials, etc.; The chemical drug preparation manufacturing park mainly develops genetic engineering drugs, new vaccines, in vitro diagnostic reagents, antibody drugs, small molecule targeted drugs, nano preparations, microsphere preparations, sustained-release and sustained-control drugs, etc.

New fine chemical materials are important basic materials for strategic emerging industries such as new energy, high-end equipment, electronic information, navigation and aerospace, rail transit, etc., and are the main direction of transformation and upgrading of the petroleum and chemical industry to achieve high-quality development. It has the characteristics of many types of products, high added value, wide use, and large industrial relevance, and can directly serve many industries of the national economy and various fields of high-tech industries. The world's manufacturing powers have taken the development of fine chemical new materials industry as a key development strategy for the upgrading and adjustment of the traditional chemical industry structure. A number of national strategic plans have clearly pointed out that it is necessary to vigorously develop the fine chemical new material industry, enhance the support capacity of the fine chemical new material industry, and promote the coordinated development of the fine chemical new material industry and the automobile, high-speed rail, aviation, biomedicine, new energy and other industries.

Company Overview: It is subordinate to China National Chemical Engineering Group Co., Ltd., which is directly under the State-owned Assets Supervision and Administration Commission of the State Council of the People's Republic of ChinaEast China Engineering Science and Technology Co., Ltd. originated from the Third Design Institute of the former Ministry of Chemical Industry of China established in 1963, implemented the shareholding system reform in 2001, and was successfully listed on the Shenzhen Stock Exchange in 2007. It is a modern science and technology enterprise that has carried out joint-stock reform and listed on the stock market earlier in China's engineering survey and design industry. As one of the top 100 survey and design enterprises in China, the company has been awarded the titles of “AAA Credit Enterprise” and “National High-tech Enterprise” for consecutive years, and was rated as “National Civilized Unit” as early as 2005.

2.3 Contact method

Contact person: Qi Shan

Tel: +86-13504315193

E-mail: 80434980@qq.com

Postal code: 138000

Contact method of the city (prefecture) where the project is located:

Contact unit: Changchun Municipal Cooperation and Exchange Office

Contact person: Zhang Junjie

Tel: +86-15704317930

Fax: +86-431-82700590

E-mail: xmc82763933@163.com