New Material

An Annual Output of 80,000 Tons of Plastic Alloy Project of Changchun City

1. Introduction to the Project

1.1 Project background

1.1.1 Project introduction

Plastic alloy is a new class of high-performance, functionalized and specialized materials obtained by physical blending or chemical grafting. Plastic alloy products can be widely used in automobiles, electronics, precision instruments, office equipment, packaging materials, building materials and other fields. It can improve or enhance the performance of existing plastics and reduce costs, and has become one of the most active varieties in the plastics industry, with very rapid growth.

1.1.2 Market prospect

(1) Classification of plastic alloy varieties

Plastic alloy is a plastic variety with better performance by fusing two or more plastics. For example, the most common PC/ABS alloy is a fusion of PC and ABS. There are many types of plastic alloys, but it does not mean that any two plastics can be fused together to make plastic alloys. Plastic alloys are also divided into two types: general plastic alloys and engineering plastic alloys. The raw materials of general plastic alloys are: PVC (polyvinyl chloride), PE (polyethylene), PP (polypropylene), and PS (polystyrene) engineering plastic alloys refer to the blends of engineering plastics (resins), mainly including PC, PBT, PA, POM (Polyoxymethylene), PPO, PTFE (polytetrafluoroethylene) and other engineering plastics as the main body of the blending system, as well as ABS resin modified materials.

(2) Plastic alloy market prospects

In recent years, the plastic alloy industry has had a profound impact on people's lives, from the market situation, industry services, service conditions, market size and other aspects to all aspects of life. The market growth is driven by:

Technological advancements: With the development of science and technology, the manufacturing technology of plastic alloys has been continuously improved, which has improved the quality and performance of products.

Emergence of new application areas: The growing applications of plastic alloys in the automotive industry, electronics industry, aerospace and other industries drive the growth of the market.

Environmental Friendliness: Compared with traditional metal materials, plastic alloys are more environmentally friendly and can reduce energy consumption and carbon dioxide emissions, which has attracted more and more attention and adoption by enterprises.

It is expected that in the next few years, the plastic alloy market will continue to maintain a rapid growth trend. However, competition in the market will also gradually intensify, and companies need to constantly innovate and improve product quality and performance to remain competitive.

The data shows that: In the market structure of service types in China's plastic alloy industry, service packaging ranks first, accounting for 28.3%, raw material processing ranks second, accounting for 25.2%, product research and development ranks third, accounting for 13.2%, and installation and construction ranks fourth, accounting for 10.3%.

To sum up, the plastic alloy market prospect is very broad. With the continuous progress of technology and policy support, the plastic alloy industry will usher in more development opportunities and challenges.

1.1.3 Technical analysis

The process of producing plastic alloys mainly includes:

(1) Preparation of raw materials: Choose the right raw materials, such as polycarbonate (PC) and acrylonitrile-butadiene-styrene copolymer (ABS). High molecular weight resin should be selected for PC to improve the mechanical properties and thermal stability of the alloy, and resin with good processing performance and impact resistance should be selected for ABS.

(2) Ingredient mixing: Add PC, ABS resin and necessary additives to the high-speed mixer in a certain proportion and stir well. The mixing time is usually controlled at 5-10 minutes to ensure that the components are fully dispersed and mixed.

(3) Melt blending: The mixed raw material is added to the twin-screw extruder for melt blending. The temperature, rotational speed and feed speed of the extruder in this process need to be controlled in the process to ensure that the components are fully melted, mixed and dispersed. At the same time, the gas in the molten material is removed through the vacuum degassing device to reduce the bubbles and voids in the product.

(4) Granulation: The melt blended material is cooled and pelletized to obtain plastic alloy particles. During the pelletizing process, the appropriate pelletizing speed and cooling water temperature should be maintained to ensure that the particle shape is regular and the particle size is uniform.

(5) Quality inspection: The quality inspection of the produced plastic alloy particles, including the appearance, particle size distribution, mechanical properties, thermal stability, etc., to ensure that the products meet the relevant standards and customer requirements.

(6) Packing and warehousing: The plastic alloy particles that pass the inspection will be packaged and marked with the product name, specification, production date and other information. After the packaging is completed, the product is put into the inventory and waiting for delivery.

1.1.4 Advantageous conditions of project construction

(1) Policy advantages

The central government issued the “14th Five-Year Plan for the Development of the Plastic Alloy Industry”, which clearly requires the alloy industry to increase by 55%, local policies have been introduced in various aspects to improve the penetration rate of the industry, and the government report of the State Council pointed out that the plastic alloy industry is conducive to improving the quality of life of the people.

The “14th Five-Year Plan for Scientific and Technological Innovation Guiding Opinions of the Plastics Processing Industry” proposes that during the “14th Five-Year Plan” period, the plastics processing industry should focus on the “five modernizations” to provide support for the high-quality development of the plastics processing industry, with specific development goals: 1) Improve the construction of innovation system; 2) Promote collaborative innovation in the industrial chain; 3) Breakthroughs in key common technologies; 4) Promote the modernization of industrial and supply chains; 5) Strengthen the supporting role of standards; 6) Promote green and sustainable development; 7) Accelerate digital transformation and improve the level of intelligence; 8) Strengthen civil-military integration.

The Yushu Municipal Government attaches great importance to the work of attracting investment, and has formulated a series of relevant policies to attract foreign investment, mainly giving preferential treatment in terms of tax collection, land transfer, and high-quality services, and maintaining the continuity and stability of policies, and specially issued the “Yushu City Incentive Measures for Promoting the Sustainable Development of the Real Economy (Revised Draft) ” (Yufa [2021] No. 18), which gives greater preferential treatment and support in terms of land and taxation.

(2) Talent advantages

Changchun is a city located in a university, with 15 national key laboratories, 83 independent scientific research institutions in Changchun, such as the Changchun Institute of Optics, Fine Mechanics and Physics of the Chinese Academy of Sciences, the Institute of Applied Chemistry of the Chinese Academy of Sciences, and the Institute of Geographic Sciences and Natural Resources Research of the Chinese Academy of Sciences, and 49 colleges and universities such as Jilin University and Northeast Normal University, which can provide senior managers and technicians for the implementation of the project.

(3) Resource advantages

Yushu City fully implements the spatial development layout of the park, relies on the existing industrial base, expands the development space, and attracts more pharmaceutical production and logistics projects such as Chinese patent medicine processing, biopharmaceuticals, and pharmaceutical intermediates to enter the park with more preferential policies, forming an agglomeration effect and driving the rapid development of the entire industry.

1.2 Contents and scale of project construction

1.2.1 Product scale

An annual output of 80,000 tons of plastic alloys.

1.2.2 Contents of Construction

Construction of plastic alloy production workshops, production lines, warehouses, administrative office buildings, etc., and purchase of a set of shopping equipment and ancillary facilities, with a capacity of 200 people.

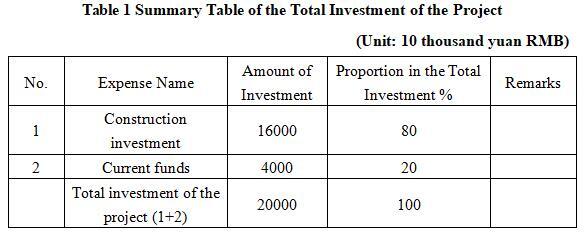

1.3. Total investment of the project and capital raising

The total investment of the project is 200 million yuan, including construction investment of 160 million yuan

1.4 Financial analysis and social evaluation

1.4.1 Main financial indexes

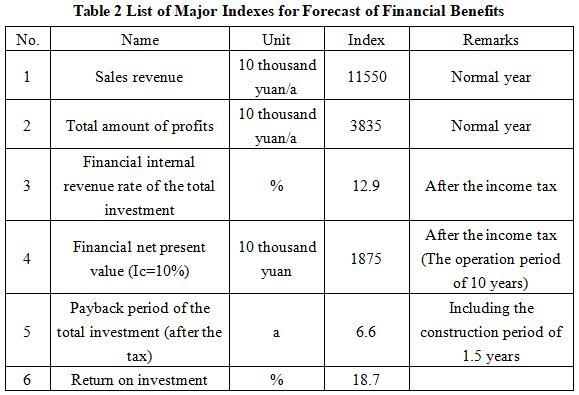

After the project reaches the production capacity, its annual sales income will be 115.5 million yuan, its profit will be 38.35 million yuan, its investment payback period will be 6.6 years (after the tax, including the construction period of 1.5 years) and its investment profit rate will be 18.7%.

Note: “10 thousand yuan” in the table is in RMB.

1.4.2 Social evaluation

By using plastic alloy materials instead of traditional materials, we reduce our dependence on resources such as wood and metal, and help conserve resources. Plastic alloy materials are usually recyclable and can be recycled and reused after multiple uses, which reduces the generation of waste, reduces environmental pollution, and has good social benefits for project construction.

1.5 Cooperative way

Sole proprietorship, joint venture and cooperation, etc.

1.6 What to be invested by the foreign party

Funds and other ways can be negotiated face to face.

1.7 Construction site of the project

Changchun Wukeshu Economic Development Zone

1.8 Progress of the project

Project proposal has been prepared

2. Introduction to the Partner

2.1 Unit basic information

Name: Changchun Wukeshu Economic Development Zone

Address: Changchun Wukeshu Economic Development Zone (31 kilometers from Yutao Highway)

2.2 Unit overview

Changchun Wukeshu Economic Development Zone is a provincial-level development zone approved by the Jilin Provincial Government on July 15, 2003, located 3 kilometers west of Yushu City. It covers an area of 804 square kilometers, with a planned core area of 45.55 square kilometers and a total population of 319,000.

In recent years, the park has successively introduced a number of well-known enterprises at home and abroad, such as COFCO Biochemical, SDIC Biotech, Thailand CP Group, American Centrient, Jindong Group, Beijing Capital Agribusiness & Foods Group, Dalian Shide Group, Sihai Group, Tongwei Group, Dalian Winning, Jilin Dadi Environmental Protection, Jilin Haichuan, Fenglin Food, etc. Up to now, there are more than 300 enterprises of all kinds stationed in the development zone, including 31 enterprises above designated size. There are 5 Fortune global 500 companies and 5 Fortune China 500 enterprises. The enterprises settled in the district solve the annual employment of 25,000 laborers. The corn biochemical park represented by COFCO Biochemical Energy (Yushu) Co., Ltd. has been preliminarily formed; The biomedical industrial park represented by Centrient Biochem Intermediate (Changchun) Limited Corporation; The Livestock and poultry products processing industrial park represented by Thailand CP Group; The liquor industry demonstration park represented by Yushuqian Liquor and 138 liquors; Characteristic industrial parks such as mass entrepreneurship and innovation industries represented by Shengkailun Mass Entrepreneurship and Innovation Base, and the infrastructure construction of Wukeshu Chemical Industry Park are improving day by day.

Wukeshu Development Zone has been successively rated as “National Agricultural Products Processing Industry Demonstration Base” by the Ministry of Agriculture, “Provincial Agricultural Products Processing Industry Demonstration Zone” by Jilin Provincial Government, and “National Top 100 Scientific Development Demonstration Parks” by the National Development and Reform Commission.

2.3 Contact method

Contact person: Li Lingang

Tel: +86-431-83060888

E-mail: yshzjl5021@163.com

Postal code: 130400

Contact method of the city (prefecture) where the project is located:

Contact unit: Changchun Municipal Cooperation and Exchange Office

Contact person: Zhang Junjie

Tel: +86-15704317930

Fax: +86-431-82700590

E-mail: xmc82763933@163.com