New Material

High-end NdFeB Permanent Magnet Material Project of Siping City

1. Introduction to the Project

1.1 Project background

1.1.1 Product introduction

Neodymium magnets, also known as neodymium-iron-boron magnets, are tetragonal crystals formed by neodymium, iron, and boron. The magnetic energy product of this magnet is greater than that of samarium cobalt magnets, and it was the substance with the largest magnetic energy product in the world at that time. This permanent magnet is the second most magnetic magnet in absolute zero to holmium magnets today, and it is also the most commonly used rare earth magnet. NdFeB magnets are widely used in electronic products such as hard drives, mobile phones, headphones, and battery-powered tools.

This product is located in Siping Economic Development Zone to build a high-end NdFeB permanent magnet material project, enhance local industrial strength, accelerate economic growth, respond to market demand for high-end materials, and promote technological progress.

1.1.2 Market prospect

(1) The development status of high-end NdFeB permanent magnet materials

In recent years, China has made remarkable progress in the field of high-end NdFeB permanent magnet materials, becoming the world's largest production and application market. Domestic enterprises have shown strong competitiveness in terms of technology, output and market share. Specifically, the technology research and development capabilities have been significantly improved, and some technologies have reached the international leading level. Production continues to grow, accounting for a major share of the global market. It has a wide range of applications, promoting the development of new energy, electronics, automobiles, medical and other industries. The industrial chain has been gradually improved, and a relatively complete industrial system has been formed.

Despite this, China's high-end NdFeB permanent magnet material industry is still facing challenges. The R&D capabilities of high-end products need to be further strengthened, the stability of raw material supply needs to be improved, and environmental protection measures need to be strengthened. In order to meet these challenges, China needs to increase R&D investment, promote technological innovation, strengthen environmental protection measures, and ensure the sustainable development of the industry. Through these efforts, China's high-end NdFeB permanent magnet material industry is expected to achieve more brilliant achievements.

At the technical level, China's R&D team has overcome a series of technical problems through unremitting efforts, so that the product performance has been continuously improved, and some technologies have reached or exceeded the international advanced level. This achievement is due to China's great attention to and continuous investment in the new material industry. In terms of output, the annual output of China's high-end NdFeB permanent magnet materials continues to grow, and has occupied more than 70% of the global market. This achievement is inseparable from the efforts and innovation of many domestic enterprises. These enterprises have not only achieved expansion in production scale, but also significantly improved product quality and stability, meeting the demand for high-end permanent magnet materials in domestic and foreign markets.

Although China has made remarkable achievements in the field of high-end NdFeB permanent magnet materials, it still faces some challenges. For example, the R&D capabilities of high-end products need to be further improved, the stability of raw material supply needs to be strengthened, and the impact on the environment in the production process needs to be improved. In order to meet these challenges, China needs to continue to increase R&D investment, promote technological innovation, and strengthen environmental protection measures to ensure the sustainable development of the industry.

(2) Prospect analysis of high-end NdFeB permanent magnet materials

With the growing global demand for clean energy and efficient energy conversion technology, the application field of high-end NdFeB permanent magnet materials is rapidly expanding. In addition to playing a key role in traditional fields such as wind power, electric vehicles, and hard disk drives, their use in emerging technologies such as magnetic resonance imaging (MRI) equipment, precision instruments, and robotics is also showing significant growth.

However, with the expansion of application fields, the performance requirements for NdFeB permanent magnet materials are also increasing. This includes not only higher energy product and better temperature stability, but also environmental friendliness and sustainability of the material. Therefore, the research and development of new, more environmentally friendly production technologies, as well as the search for alternative materials to reduce dependence on rare earth elements, have become the new direction of the industry's development.

In addition, the stability of the global supply chain and the volatility of raw material prices have also had an important impact on the market outlook of NdFeB permanent magnet materials. To reduce risk, manufacturers and end-users are looking to diversify their sources of supply and explore technologies to recycle old magnets to reduce the need for new resources.

To sum up, the market prospect of high-end NdFeB permanent magnet materials is still optimistic, but it also faces many challenges. Only through the combination of technological innovation, supply chain management and environmental sustainability strategies can we ensure a stable supply of this critical material in the long term and promote the sustainable development of related industries.

1.1.3 Advantageous conditions of project construction

(1) Policy conditions

The national “14th Five-Year Plan” for the development of raw material industry points out that the key directions of technological innovation: high-performance rare earth permanent magnet materials, selective precise penetration and other technologies; New materials focus on breakthroughs in varieties, high-performance rare earth permanent magnet materials, create a number of rare earth industrial clusters, expand and strengthen rare earth enterprise groups, and strengthen the upstream and downstream cooperation mechanism of rare earth permanent magnet materials for new energy vehicle drive motors. The performance requirements for high-performance neodymium ferromagnet permanent magnets are specified in the “Catalogue of Guidance for the First Batch of Application of Key New Materials”.

(2) Advantages of industrial base

At the beginning of the founding of the People's Republic of China, a number of ministries and commissions of the state have successively built harvesters, blowers, loaders, buses and combined, oily and other enterprises in Siping, the first combine harvester in New China was born in Siping, and Baishan brand buses are all over the country. After the reform and opening up, after years of development, a new industrial system has been built, and three key industries have been formed currently: Equipment manufacturing industry led by special-purpose vehicles, buses, construction machinery, heat exchangers, and automotive parts. New energy industry led by petroleum, natural gas, thermal power, wind power, biomass power generation and solar power generation; Agricultural products deep processing industry led by deep processing of grains and livestock products. Among them, the special-purpose vehicle industry is the most crucial industry to be established by Siping, which has a good development prospect and broad development space.

(3) Location advantages

Siping is the core of the entire Northeast Asia region and is the city with the shortest transportation radius. Overlooking the 17.28 million square kilometers of Northeast Asia, the geometric center point is in Siping, reaching the Bohai Economic Circle in the south, Russia in the north, the Korean Peninsula in the east, and Mongolia in the west. Siping is located at the junction of Liaoning, Jilin and Inner Mongolia provinces, in the center of the Northeast Automobile Industry Belt, with access to Heilongjiang, Jilin, Liaoning and Inner Mongolia Eastern Four Leagues. It is the nearest city and the only way for Jilin, Heilongjiang and eastern Inner Mongolia to lead to the coastal ports and the Bohai Economic Circle, with a land area of 1.24 million square kilometers, accounting for 12.9% of the total land area in China, and a total population of 107 million. With convenient transportation extending in all directions and crossing railway and highway network, Siping is an important node city on the Harbin-Dalian traffic artery; Beijing-Harbin Railway, Harbin-Dalian High-speed Railway, Harbin-Sanya Expressway, Changchun-Shenzhen Expressway, Daqing-Guangzhou Expressway, National Highway 102 and so on intersect in Siping.

1.2 Contents and scale of project construction

With a total area of 14 acres, the project is planned to build major production plants such as smelting workshop, milling workshop, sintering workshop, machining workshop, etc., as well as auxiliary projects and public works such as power distribution room and cooling pool; Purchase and install major production equipment such as vacuum strip throwing furnaces, hydrogen blasting furnaces, jet mills, forming presses and vacuum sintering furnaces, and life auxiliary equipment such as power distribution systems, heating systems, and transportation systems.

1.3 Total investment of the project and capital raising

1.3.1 Total investment of the project

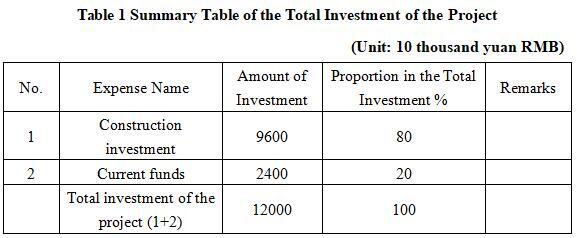

The total investment of the project is 120 million yuan, including the construction investment of 96 million yuan

1.4 Financial analysis and social evaluation

1.4.1 Main financial indexes

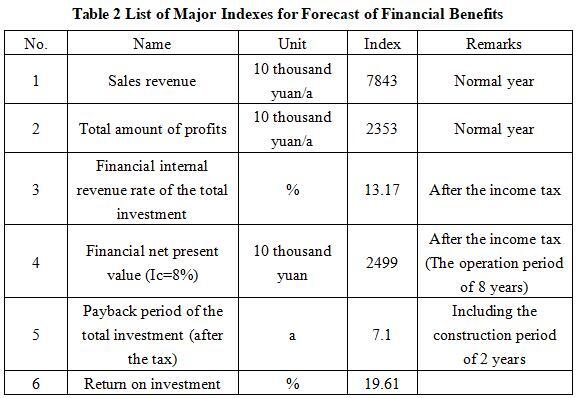

After the project reaches the production capacity, its annual sales income will be 78.43 million yuan, its profit will be 23.53 million yuan, its investment payback period will be 7.1 years (after the tax, including the construction period of 2 years) and its investment profit rate will be 19.61%.

Note: “10 thousand yuan” in the table is in RMB.

1.4.2 Social evaluation

The implementation of the project has played a significant role in promoting local economic prosperity, bringing new economic growth points to the local area and attracting investment from many related industries, thus forming a dynamic industrial cluster. With the expansion of the industrial scale, a large number of jobs have been created, providing abundant employment opportunities for local residents, effectively alleviating employment pressure and improving the living standards of residents. In addition, the promotion of the project has also led to the construction and improvement of the surrounding infrastructure, improved the overall development level of the region, and laid a solid foundation for the long-term stability and harmony of the society.

1.5 Cooperative way

Joint venture and cooperation.

1.6 What to be invested by the foreign party

Funds and other ways can be negotiated face to face.

1.7 Selected project site

Siping Economic Development Zone.

1.8 Progress of the project

Project planning stage.

2. Introduction to the Partner

2.1 Unit basic information

Name: Siping Economic Development Zone Administrative Committee

Address: No. 1699, Kaifa Road, Economic Development Zone, Siping City

2.2 Overview

Siping Economic Development Zone is located at the southernmost end of Jilin Province, bordering Liaoning, between Shenyang City of Liaoning Province and Changchun City of Jilin Province, 180 kilometers from Shenyang (45 minutes of high-speed railway) and 100 kilometers (27 minutes of high-speed railway) from Changchun. It is the main traffic throat of the four provinces of Heilongjiang, Jilin, Liaoning and Inner Mongolia. The total planning area is 71.41 square kilometers, with automotive parts, medicine and food and modern service industry as the leading industries.

One 220kV substation in the zone: The substation capacity is 240,000 KVA, and the total capacity of the three 66 KV substations is 133,000 KVA. Can realize double-circuit power supply and enjoy the preferential policy of directly purchasing electricity, thereby reducing the production cost of enterprises. The wastewater discharge pipeline network in the Economic Development Zone is fully connected to the municipal pipeline network of the main urban area, with a daily treatment capacity of 180,000 tons, meeting the wastewater treatment needs of enterprises. Currently, the industrial steam pipeline with a total length of 8 kilometers has been put into use, and the pipeline has been laid close to the red line of the park, which can meet the needs of enterprises. Guided by a series of national strategy for revitalization of old industrial base in Northeast China, and supported by the implementation opinions of Jilin Provincial People's Government on promoting the reform and innovative development of the Development Zone, in combination with the “Preferential Policy for Investment Promotion in Siping City”, the “Preferential Policy for Investment Promotion in Siping Economic Development Zone” is formulated. For the projects with large investment volume and strong industrial driving capacity, “one project, one discussion” is implemented to support the projects with greater preferential policies to enhance the confidence of enterprises to invest in the Zone.

2.3 Contact method

2.3.1 Contact method of cooperator

Project Unit: Investment Promotion Bureau of Siping Economic Development Zone

Contact Person: Hu Jing

Tel: +86-13844400042

2.3.2 Contact method of the city (prefecture) where the project is located

Contact unit: Siping City Economic Cooperation Bureau

Contact person: Wen Dacheng

Tel: +86-434-3260536

E-mail: spjhjjhk@163.com