New Material

Soft Magnetic Material Industrial Park Construction Project of Tonghua City

1 Introduction to the Project

1.1 Project background

1.1.1 Product introduction

Magnetic materials are important functional materials with wide applications and a wide variety of applications, which can be divided into soft magnetic, permanent magnet and other materials according to the type of application. Among them, soft magnetic materials are special materials with high permeability, low coercivity and low hysteresis loss, which are not only easy to be magnetized by the applied magnetic field, but also easy to demagnetize, and its main role is to realize the conversion of magnetic permeability and electromagnetic energy and signal processing. Soft magnetic materials are widely used in transformers, inductors, sensors, motors (generators, motors) and other power conversion equipment, and are important materials in the era of electronic power.

The project is planned to build a soft magnetic material industrial park in Huinan Economic Development Zone, which is divided into two parts: a soft magnetic material industrial park and a soft magnetic material product production project. The soft magnetic material industrial park attracts soft magnetic material production enterprises involved in the field of science and technology to settle in, and the soft magnetic material product production project produces 3,000 tons of soft magnetic materials annually. The construction of the project can promote the development of the new material industry in Tonghua area.

1.1.2 Market prospect

(1) The current situation of the soft magnetic materials market

Soft magnetic materials are magnetic materials with low coercivity and high permeability, which means that when magnetization occurs in Hc is not more than 1,000A/m, such materials are called soft magnets. A typical soft magnetic material can achieve maximum magnetization with a minimum external magnetic field.

There are many kinds of soft magnetic materials, which can be mainly divided into ferrite soft magnetic materials, metal soft magnetic materials and other soft magnetic materials, among which ferrite soft magnetic materials can be divided into manganese-zinc ferrite materials, nickel-zinc ferrite materials, and other ferrite materials; Metal soft magnetic materials can be divided into industrial pure iron and traditional alloys, amorphous and nanocrystalline alloys and metal magnetic powder cores, of which metal magnetic powder cores can be divided into iron powder cores, iron-silicon magnetic powder cores, iron-silicon aluminum magnetic powder cores, iron-nickel magnetic powder cores and permalloy magnetic powder cores.

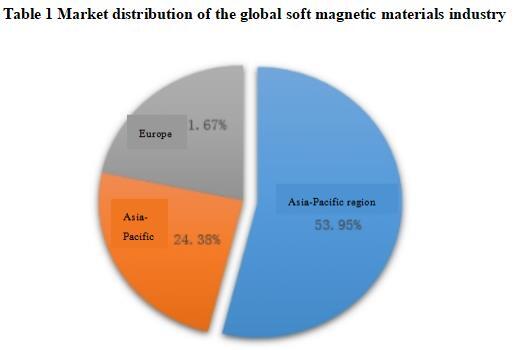

Soft magnetic materials are widely used in power electronics, communication electronics, computers, photovoltaic inverters, new energy vehicles and other fields, and with the development of these industries, the market size of the global soft magnetic materials industry is also growing. From the perspective of market distribution, the highest market share of the global soft magnetic materials industry is in the Asia-Pacific region, accounting for 53.95%; Followed by North America, with a market share of 24.38%; the third is the European region, accounting for 21.67%.

With the implementation of the global dual-carbon strategy and the rapid development of downstream industries such as new energy and new energy vehicles, clean, environmentally friendly, low-carbon, and efficient new energy applications have brought new needs for high efficiency and high power density in power energy conversion, coupled with the continuous expansion and penetration of soft magnetic materials in emerging application markets, the market size of soft magnetic materials continues to grow, and the global market size was about 200 billion yuan in 2022.

China is the global production center and main consumer market of magnetic materials, and the magnetic material industry has a broad space. There are more than 1,000 magnetic material manufacturers in China, including supporting equipment and auxiliary raw material manufacturers. At present, China has built a complete range of magnetic material industry, and the output of various types of magnetic materials ranks first in the world, and has established the status of the world's largest producer of magnetic materials and the center of the magnetic material industry.

(2) The current situation of the ferrite soft magnetic materials market

As an important part of basic functional magnetic materials, soft magnetic ferrite has been widely used in many fields, and its main component is ferromagnetic oxide of ferric oxide, which is usually produced by advanced powder metallurgy process. These ferrites are favored for their excellent characteristics of high permeability, high resistivity, and low losses at high frequencies, as well as ease of mass production, good performance stability, excellent machinability, and relatively low manufacturing costs.

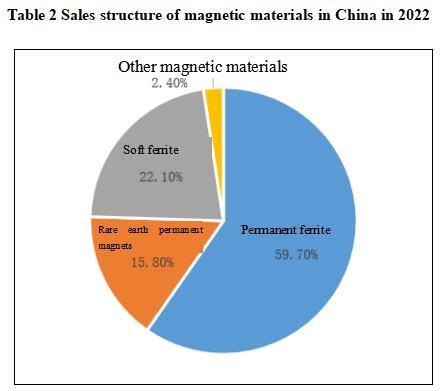

Soft magnetic materials are a kind of magnetic materials, and from the perspective of sales proportion, in 2022, the sales volume of soft ferrite in the overall sales of magnetic materials in China accounted for 22.1%, ranking second in the sales volume of magnetic materials in the whole market.

The upstream of the ferrite soft magnetic industry chain mainly involves the steel industry, chemical raw materials and chemical products manufacturing industry, and the main raw materials for production include iron oxide, manganese oxide and zinc oxide. The downstream of ferrite soft magnetism is mainly the core manufacturer, which is mainly used to process different types of electronic transformers, inductors and other electronic magnetic components in the power supply circuit. It is mainly used in household appliances, photovoltaic power generation, consumer electronics, etc.

The production of ferrite soft magnetism in China started in the 50s and 60s of the 20th century. Benefiting from the drive of the home appliance industry chain, the industrial production of ferrite soft magnetism in China has developed rapidly from the 80s to the 90s of the 20th century, the number of enterprises has been increasing, and the scale of output has expanded rapidly. Well-known foreign magnetic material manufacturers have gradually increased their investment and construction efforts in China, driving the improvement of China's magnetic material production scale, production technology and product performance.

With the vigorous development of photovoltaics, wind energy, new energy vehicles and 5G communications in China, the market demand for key materials such as soft ferrite is also rising. Thanks to the strong support and guidance of the Chinese government, the ferrite soft magnetic material industry is gradually moving towards the development path of standardization, high performance and order, and at the same time strengthens the close connection with the main bodies of the upstream and downstream links of the industrial chain, and is committed to creating a magnetic material industry cluster with strong competitiveness.

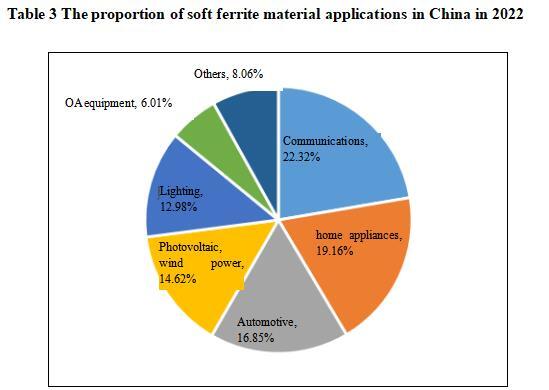

Soft ferrite materials are widely used in the downstream of the industrial chain, among which communications, home appliances and automobiles are the three main application fields of ferrite soft magnetic materials in China, accounting for 22.32%, 19.16% and16.85% of the total demand, respectively. In the field of communication, it is mainly used in magnetic antennas, electromagnetic containers, power switches and filters such as mobile phones, chargers, base stations, and programmable switches. With the accelerated deployment of 5G technology, the demand in this field is expected to increase further. According to the survey, the proportion of soft ferrite material applications in China in 2022 is as follows:

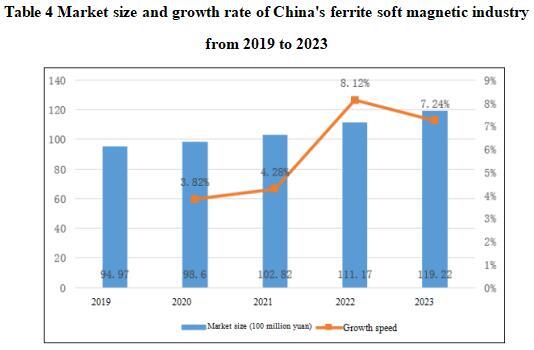

In 2023, the sales volume of ferrite soft magnetic in China was about 510,000 tons, a year-on-year increase of 5.8%. In 2019, the market size of China's ferrite soft magnetic industry was 9.497 billion yuan, and in 2023, the market size of China's ferrite soft magnetic industry was 11.922 billion yuan. The compound annual growth rate is about 5.87%.

At present, the main manufacturers of soft ferrite materials in China include Ningbo Yunsheng Gaoke Magnetics Co., Ltd., Jiangxi Yingtai Magnetoelectric Co., Ltd., Hengdian Group Dmegc Magnetics Co., Ltd., Tiantong Holding Co., Ltd., and Beijing Zhongke Sanhuan High-tech Co., Ltd. These businesses can be broadly divided into two categories: Large enterprises and small and medium-sized enterprises. Among them, large enterprises include Ningbo Yunsheng Gaoke Magnetics Co., Ltd., Jiangxi Yingtai Magnetoelectric Co., Ltd. and Hengdian Group Dmegc Magnetics Co., Ltd., which are larger in scale, have strong technical strength and brand advantages, and have a large market share. Small and medium-sized enterprises include Tiantong Holding Co., Ltd. and Beijing Zhongke Sanhuan High-tech Co., Ltd., which are small in scale but also have a certain competitiveness in some areas.

At present, the global manufacturing industry is undergoing profound changes in the direction of digitalization, informatization and intelligence. Modern information technology is gradually being combined with the traditional production of soft ferrite. At present, soft ferrite enterprises are generally facing the problems of low added value and rising labor costs. Promoting intelligent manufacturing production can effectively improve product consistency, reduce production costs, improve production efficiency, realize industrial transformation and upgrading, and improve enterprise efficiency. Large production enterprises in the industry are improving the application level of production line automation.

(3) The current situation of the metal soft magnetic powder core market

Metal soft magnetic is widely used, with an annual output of more than one million tons in the world, and can continue to be subdivided into pure iron, silicon steel, permalloy, metal soft magnetic powder core and other categories, among which metal soft magnetic powder core has excellent performance and is widely used in photovoltaic, energy storage, new energy vehicles and other sectors.

Metal soft magnetic powder core is a soft magnetic material pressed by magnetic powder coated with insulating medium, and it is the soft magnetic material with the best comprehensive performance in the field of soft magnetic materials today. The soft magnetic powder core combine its magnetic properties with the advantages of metal soft magnetic materials and soft ferrite. Its powder is made of ferromagnetic particles, so the saturation magnetic induction intensity is high, and because of the existence of an insulating layer, its resistivity is also high. In terms of molding process, it is more mature than amorphous soft magnetic and has strong plasticity. The soft magnetic powder core can meet the needs of high frequency (KHz~MHz) use and volume miniaturization at the same time, and can be processed into ring, E-type, U-shaped, etc., to meet different applications.

With the development of various electronic products in the direction of micromation and miniaturization, metal soft magnetic powder cores can better meet the requirements of high efficiency, high power density and high frequency of power conversion equipment by virtue of their excellent characteristics such as good temperature characteristics, low loss and high saturation flux density, and the market prospect is particularly prominent in recent years. Metal soft magnetic powder cores are closely related to the new energy industry, and can be widely used in photovoltaic power generation, new energy vehicles and charging piles, data centers, energy storage, inverter air conditioning, consumer electronics, power quality remediation and other fields.

In recent years, with the continuous development of science and technology and the advancement of industrial transformation and upgrading, superimposed on the changes in people's living standards and methods, the demand for new energy vehicles, mobile phones, computers and other new products has gradually increased, which has led to the continuous rise in the demand for metal soft magnetic materials, prompting the emergence of a large number of metal soft magnetic material manufacturers in China, and the development trend of the industry is relatively good. By the end of 2023, there will be 7,886 enterprises related to metal soft magnetic materials in China, a year-on-year increase of 45.96%. At present, the key enterprises in China's metal soft magnetic powder core industry mainly include Boke New Materials.

At present, the demand for metal soft magnetic powder cores for photovoltaics, energy storage, new energy vehicles and charging piles is in a stage of rapid growth. With the continuous upgrading of electronic devices and the emergence of new applications, the metal soft magnetic powder core market has huge growth potential.

1.1.3 Advantageous conditions of project construction

(1) Policy advantages

In January 2017, the “New Materials Industry Guide” proposed to focus on the new generation of information technology industry, high-end equipment manufacturing industry, etc., focusing on rare earth functional materials such as high-performance permanent magnets, high-efficiency luminescence, and high-end catalysis to achieve industrialization and large-scale application.

In February 2017, the “Guiding Catalogue of Key Products and Services in Strategic Emerging Industries” clearly included “high-end special materials such as magnetic materials, functional metal powder materials, and soft magnetic composite materials” in the guiding catalogue.

In April 2019, the “Guidance Catalogue for Industrial Structure Adjustment” proposed to encourage the development of high-quality rare earth magnetic materials and high-end applications.

In March 2021, the “Outline of the 14th Five-Year Plan for National Economic and Social Development of the People's Republic of China and the Long-Range Objectives Through the Year 2035” proposed to focus on strategic emerging industries such as new materials, accelerate the innovation and application of key core technologies, enhance the ability to guarantee factors, and cultivate and expand new momentum for industrial development.

In December 2021, the “14th Five-Year Plan for the Development of Raw Material Industry” proposed to strictly control the total production capacity of magnetic materials to prevent them from growing too quickly, avoid the imbalance between market supply and demand and vicious competition caused by excessive growth in production capacity, focus on the reform of the industry's supply-side structure, continuously optimize the industry's production capacity and product structure, and increase effective supply.

In August 2022, the Ministry of Industry and Information Technology and other departments issued the “Implementation Plan for Carbon Peaking in the Industrial Sector”, proposing to vigorously promote the improvement of production processes such as monocrystalline silicon, electrode foil, magnetic materials, lithium battery materials, electronic ceramics, electronic glass, optical fibers and optical fiber preforms.

In March 2023, the National Development and Reform Commission agreed to set up a demonstration zone for undertaking industrial transfer in southwest Jilin, focusing on improving industrial undertaking capacity, optimizing the business environment, deepening open cooperation, effectively undertaking domestic and foreign industrial transfer, promoting industrial transformation and upgrading in the process of undertaking, and striving to build the demonstration zone into a characteristic manufacturing base in Northeast China, a pilot area for green and low-carbon transformation, a new highland for regional cooperation and development, and an important processing base for special agricultural products in China. The scope of the demonstration area includes the three cities of Siping, Liaoyuan and Tonghua.

(2) Industrial advantages

Huinan Economic Development Zone has planned four functional zones, namely a comprehensive industrial development zone, a residential and living supporting zone, a trade and logistics development zone, and an office and industrial innovation zone. In addition, Huinan Economic Development Zone has also planned four industrial bases, namely the small and medium-sized enterprise incubation base, the Northeast pharmaceutical packaging industry base, the Northeast steel products deep processing industry base and the Northeast agricultural products deep processing industry base.

Jilin Huaxing Powder Metallurgy Technology Co., Ltd. is an excellent powder metallurgy enterprise in China, located in Huinan Economic Development Zone, which is a high-tech enterprise integrating production, research and development and sales of ultra-pure reduced powder. The company has iron ore reserves of 5.6 million tons, an annual production of 200,000 tons of high-quality iron ore powder, an annual casting capacity of more than 5,000 tons, and an annual production of 10,000 tons of ultra-fine reduced iron powder. It is a company specializing in the production of high-precision, high-strength, high-density and high-performance iron-based metallurgical powder products. At present, the company has passed the ISO-2008 quality system certification, obtained the national high-tech enterprise certification, has a number of invention and utility model patents, and won the title of Jilin R&D Center in 2014; In 2016, it was awarded the title of high-tech enterprise. The technical indicators of the company are better than the national standards, and the sales customers are all over Jiangsu, Guangdong, Zhejiang, Fujian and exported to South Korea, Japan, Taiwan and other countries and regions. From 2013 to 2014, high-pressure water atomized ferrosilicon powder and iron-silicon-aluminum powder self-developed by the company were successfully put into the market and applied to high-end soft magnetic product manufacturers. Among them, there are only 3 domestic enterprises that can produce ferrosilicon soft magnetic products, and the quality of Huaxing's products is far ahead in China. The company can provide sufficient raw materials for related enterprises.

(3) Location advantages

Huinan County is backed by the treasure house of resources in the Changbai Mountains, facing the rich granary of the Songliao Plain, which is the transition zone between the Changbai Mountains and the Songliao Plain, and has always been the western gateway to the Changbai Mountains. Huinan County is located in the hinterland of the Asia-Pacific Economic Circle, and is the gathering point of Changchun, Jilin and Tumen development and opening up pilot areas and Tonghua, Dandong and Dalian economic belt. The unique location advantage provides a superior platform for the economic development of Huinan County.

Huinan County is located in the center of Shenyang, Changchun, Fushun, Siping, Jilin, Tonghua and other large and medium-sized cities, with convenient highways and railways in all directions, and convenient transportation by sea and air. With the convenient transportation environment, Huinan County has been included into the one-hour economic circle of Changchun, Jilin, Tonghua and Baishan, the two-hour economic circle of Shenyang, Siping and Fushun, and the five-hour economic circle of Dalian, Dandong and Tumen. It is easy to accept the economic radiation of Shenyang, Changchun, Dalian, Jilin and other large cities, so as to become a regional industrial and commercial center.

(4) Talent advantages

At present, Tonghua City has 3 national key secondary vocational schools, 3 provincial key secondary vocational schools, and the county-level vocational education centers have all passed the acceptance of the provincial key schools and entered the ranks of the top 100 schools in the province, which is the first region in the province with all county-level vocational education centers entering the ranks of provincial key schools. In recent years, through scientific layout, we have continuously promoted the structural adjustment and resource integration of vocational education, explored new paths for diversified schooling, and continuously improved the construction of modern vocational education network system, the local characteristics of vocational education have begun to take shape, and the ability to serve economic and social development has been gradually improved.

Tonghua Municipal Government has signed scientific and technological strategic cooperation agreements with Northeast Normal University, Jilin Agricultural University, Changchun Institute of Applied Chemistry, Chinese Academy of Sciences, Tonghua Normal University and other universities in the province, providing scientific and technological support for the development of enterprises. Tonghua City continues to help enterprises in talent cultivation and other aspects, vigorously implements the “Plan for 10,000 Students Rejuvenating Enterprises” and “Plan for 1,000 Students Returning”, and continues to attract college graduates for enterprises.

1.2 Contents and scale of project construction

1.2.1 Product scale

The construction of the project is divided into two parts: the soft magnetic material industrial park and the soft magnetic material product production project.

The enterprises settled in the soft magnetic materials industrial park cover production enterprises in the fields of communication equipment, automation control, new energy vehicles and charging piles, 5G base stations, aerospace and other scientific and technological fields involved in soft magnetic materials.

After the completion of the soft magnetic material product production project, the annual production of soft magnetic materials will be 3,000 tons.

1.2.2 Contents of project construction

With an area of 100,000 square meters and a construction area of 120,000 square meters, the soft magnetic material industrial park is planned to build R&D centers, office buildings, production workshops, warehouses and supporting facilities to attract soft magnetic material enterprises to settle in.

With an area of 40,000 square meters and a construction area of 40,000 square meters, the soft magnetic material product production project is planned to construct office buildings, production workshops, warehouses and supporting facilities, and purchase soft magnetic material production lines to produce soft magnetic materials.

1.3 Total investment of the project and capital raising

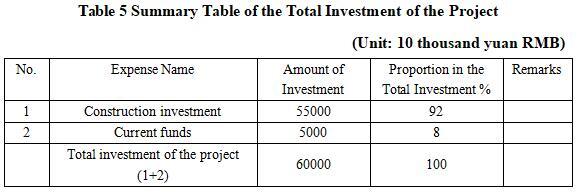

1.3.1 Total investment of the project

The total investment of the project is 600 million yuan, including construction investment of 550 million yuan and current funds of 50 million yuan.

1.3.2 Capital raising

Self-funded by enterprises.

1.4 Financial analysis and social evaluation

1.4.1 Main financial indexes

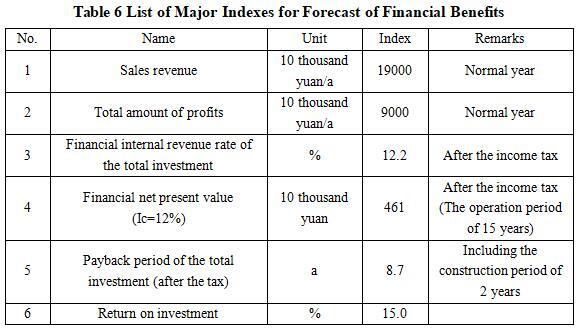

After the project reaches the production capacity, its annual sales income will be 190 million yuan, its profit will be 90 million yuan, its investment payback period will be 8.7 years (after the tax, including the construction period of 2 years) and its investment profit rate will be 15.0%.

Note: “10 thousand yuan” in the table is in RMB.

1.4.2 Social evaluation

As an important form of spatial agglomeration for regional economic development, the soft magnetic material industrial park can drive the development of related industries and form industrial clusters. This kind of cluster effect can not only promote the growth of the local economy, but also attract more investment and talents, and further promote regional economic development and industrial upgrading.

1.5 Cooperative way

Joint ventures, cooperation, and other ways are negotiable.

1.6 What to be invested by the foreign party

Funds, equipment and technology.

1.7 Construction site of the project

Huinan Economic Development Zone.

1.8 Progress of the project

The project proposal has been prepared.

2 Introduction to the Partner

2.1 Basic information

Name: Huinan County Bureau of Commerce

Address: No. 100, Chaoyang Street, Chaoyang Town, Huinan County

2.2 Overview

Huinan is the land of booming in Longgang Longwan and the hometown of fish and rice in Huinan, with an area of 2,275 square kilometers, an urban planned area of 17.75 square kilometers, a built-up area of 11.85 square kilometers, a population of 320,000, a permanent population of 237,000, 31 ethnic groups, 10 towns and 1 township, 3 streets and 1 provincial economic development zone, 143 administrative villages, 1.21 million mu of cultivated land, and a stable annual grain output of more than 1 billion catties. Known as “Six Towns and Five Counties”, in recent years, it has successively won the honorary titles of National Ecological Civilization Construction Demonstration Zone, National “Lucid Water and Lush Mountains are Invaluable Assets” Practice and Innovation Base, National Rural Revitalization Demonstration County, National Key County of Leisure Agriculture, National Demonstration County of “Four Good Rural Roads”, one of the Third Batch of National Demonstration Counties for Urban and Rural Transportation Integration, National Science Popularization Demonstration County, National Demonstration County for the Protection of Minors, one of the Fifth Batch of Water-saving Social Construction Standard Counties, and “Safe Jilin” Construction Advanced County. In 2022, it ranked second in the province in the performance assessment of the rural revitalization strategy, and ranked eighth in the province in the comprehensive evaluation of county-level economic revitalization and development.

In 2023, the county's gross domestic product (GDP) reached 10.27 billion yuan, an increase of 6.0% over the previous year. Among them, the added value of the primary industry was 2.47 billion yuan, an increase of 4.5%; the added value of the secondary industry was 2.42 billion yuan, an increase of 7.4%; The added value of the tertiary industry was 5.37 billion yuan, an increase of 6.1%. The proportion of the three industries is 24.1: 23.6: 52.3.

2.3 Contact method

2.3.1 Contact method of cooperator

Contact unit: Huinan County Bureau of Commerce

Contact person: Liu Qi

Tel: +86-435-8222071

E-mail: hnjh2071@163.com

2.3.2 Contact method of the city (prefecture) where the project is located

Contact unit: Tonghua Municipal Bureau of Commerce

Contact person: Wang Liangchen

Tel: +86-435-3199017

+86-18643036783

E-mail: thsswjtck@126.com