New Material

Light Aluminum Alloy Intelligent Manufacturing Project of Yanbian Prefecture

1. Introduction to the Project

1.1 Project background

1.1.1 Project introduction

Light aluminum alloy is an alloy made with aluminum as the main element by adding other alloying elements such as copper, magnesium, zinc, etc. Light aluminum alloy has multiple advantages such as light weight, high strength, corrosion resistance, strong thermal conductivity and heat dissipation, and high machinability, and is widely used in various fields.

The upstream raw materials of light alloys mainly include aluminum, magnesium, sodium, potassium, calcium, strontium, barium and other metal elements, which are alloyed to form materials with special physical and chemical properties. Due to its lightweight, high strength, corrosion resistance and other characteristics, light alloys are widely used in aerospace, automobile manufacturing, building structures, electronic appliances and other fields. In the aerospace field, light alloys are used to make key components such as aircraft fuselages and engine parts to improve the performance of aircraft and reduce energy consumption; In automotive manufacturing, light alloys are used to reduce vehicle weight and improve fuel economy and safety; In building structures, light alloys can be used to make support structures and curtain wall systems for high-rise buildings to improve the stability and aesthetics of buildings; In the field of electronic appliances, light alloys are often used in the manufacture of portable electronic products such as mobile phone shells and laptops to meet consumers' needs for lightweight, thin and portable products. In short, light alloy, as a high-performance and multi-functional metal material, has become one of the important pillars of modern industrial and technological development.

1.1.2 Market prospect

(1) Characteristics and applications of light aluminum alloys

Characteristics:

① Lightweight: Lightweight aluminum alloys are less dense than traditional materials such as steel and copper, so they are lightweight. For example, the density of aluminum-magnesium alloy (Al-Mg) is only 2.68 g/cm³, while the density of ordinary carbon steel is 7.85 g/cm³.

② High strength: For different application scenarios, different elements are added to light aluminum alloy to adjust its mechanical performance index, so that it has different strength and toughness.

③ Excellent electrical and thermal conductivity: Aluminum is a good conductive and thermally conductive material, so light aluminum alloy also has good electrical and thermal conductivity.

④ Corrosion resistance: Aluminum has the advantage of corrosion resistance, so light aluminum alloys also have this feature.

Applications of light aluminum alloys:

①Aviation: Aerospace components need to have the characteristics of high strength, lightness and corrosion resistance, so light aluminum alloys are widely used in the aviation field, such as fuselage, wheels, aircraft engine parts, etc.

②Automotive: The automobile manufacturing industry is also an important application field for light aluminum alloys. A large number of aluminum alloy materials are used in automobile bodies, engine covers, wheel hubs, frames, suspension systems, braking systems, etc.

③ Electronics: The conductivity of aluminum alloy materials is significantly better than that of steel and plastic materials, so it is widely used in the field of electronics, such as electronic shells, electronic shells, etc.

In other fields, light aluminum alloy also has some application scenarios, such as sports equipment, shipbuilding, construction, etc.

(2) Analysis of the development status and prospect of the aluminum alloy building formwork industry

In recent years, the market scale of the aluminum alloy formwork industry has achieved rapid growth, and it has continued to penetrate into the field of housing construction and grassroots construction. With the continuous advancement of urbanization and the continuous development of the construction industry, the market demand for aluminum alloy formwork continues to expand, and the operating efficiency continues to improve. However, affected by the downturn in the real estate market, the number of aluminum alloy formwork in the national construction market in the middle of 2024 was 61.47 million square meters, a decrease of 6.3% from the same period in 2023. As of mid-2024, there are more than 200 aluminum alloy formwork-related enterprises in China, compared with about 350 to 500 by the end of 2023. However, with the gradual introduction of national and local policies, the real estate market has gradually recovered, and the “three major projects” such as affordable housing construction, “level-emergency dual-use” public infrastructure construction, and urban village transformation have been actively promoted, providing new development opportunities for the aluminum alloy formwork industry.

In the second half of 2024, the scale of the aluminum alloy market is currently quite large. It is an important material not only widely used in aerospace, automobile manufacturing, construction engineering and other fields, but also widely used in many consumer products such as electronic products and household goods. With the continuous innovation of technology and the acceleration of industrialization, the potential of the aluminum alloy market is gradually emerging. In the future, with the deepening of global economic integration and the increase in people's demand for lightweight materials, the scale of the aluminum alloy market is expected to show a more considerable growth trend.

1.1.3 Technical analysis

The aluminum alloy manufacturing process mainly includes the following steps:

Melting & Casting: This is the first step in the manufacture of aluminum alloys, where the raw material is melted in a high-temperature melting furnace to form a liquid alloy. The liquid alloy is then poured into a mold and cooled to form a preliminary aluminum alloy casting.

Extrusion: Extrusion is the process of shaping aluminum alloy castings through an extruder. In this process, the casting is subjected to pressure at high temperatures to obtain the desired shape and size.

Heat treatment: Heat treatment is an indispensable part of aluminum alloy processing; Through heat treatment, the internal structure of aluminum alloy materials can be changed, and its strength and hardness can be improved to meet different application needs.

Machining: This step includes cutting, grinding and other operations on the aluminum alloy material to further refine the aluminum alloy material to meet the accuracy requirements of the finished or semi-finished product.

Surface treatment: Through polishing, spraying and other operations, the appearance quality and corrosion resistance of aluminum alloy materials are improved.

Quality Inspection: Conduct quality inspection on aluminum alloy materials and finished products to ensure that they meet quality requirements and ensure performance and reliability.

1.1.4 Advantageous conditions of project construction

(1) Policy advantages

In November 2024, the Ministry of Finance and the State Administration of Taxation of The People's Republic of China issued the Announcement on Adjusting the Export Tax Rebate Policy: From December 1, 2024, the export tax rebate for aluminum products (including 24 tariff codes such as aluminum strips, aluminum foils, aluminum tubes, aluminum tube accessories and some aluminum bar profiles) will be cancelled. This policy adjustment aims to guide the high-quality development of domestic aluminum enterprises and promote China's transformation from a major aluminum industry country to an aluminum industry power.

(2) Location advantages

Longjing is the frontier of the Changchun-Jilin-Tumen development and opening up pilot area, and is also the core of the Tumen River regional international cooperation and Yanji-Longjing-Tumen integration construction, 18 kilometers away from Yanji City, the capital of the autonomous prefecture, 13.5 kilometers away from Yanji Airport, an important international airport in the east of Jilin Province, 110 kilometers away from Hunchun City, the starting point of the new route from Hunchun to Zarubino, and the Longjing border line is 142.5 kilometers long, with two national land ports of Sanhe and Kaishantun, and Sanhe Port is 86 kilometers away from the Qingjin Port of North Korea. It is about 1,000 kilometers away from the port of Niigata in Japan, and is an ideal passage for China to enter the Sea of Japan through Korea.

(3) Advantages of investment services

As the frontier of the development and opening up of Yanbian and an important part of the integration of Yanji-Longjing-Tumen, Longjing City enjoys the preferential policies for the revitalization of the old industrial base in Northeast China, the policy of large-scale development of the western region, the policy of key counties in the national poverty alleviation and development work, the policy of ethnic minorities in the border areas, the policy of ethnic trade, and the support of the national action project to rejuvenate the border and enrich the people. These preferential policies provide a superior external environment and a strong external driving force for the further development of Longjing. At the same time, with the help of the advantages of Sanhe and Kaishantun ports, we will make every effort to promote the construction of cross-border cooperation zones, inter-market trade zones and cargo channels, so as to gradually build Longjing into an open city with “interconnection, domestic trade and foreign transportation”.

Focusing on strengthening services for foreign investment, we will fully rely on the government affairs hall to implement one-stop services and provide special personnel to handle the whole process of investment projects, and give priority to ensuring all comprehensive services required by foreign-invested enterprises in construction, production and life. Implement the system of one-stop office and completion time limit commitment system, and handle various pre-project approval, approval and other procedures for projects that reach a certain investment amount to ensure that the project starts as scheduled.

1.2 Contents and scale of project construction

The project covers a total area of 100,000 square meters, and the first and second phases cover an area of 50,000 square meters each. The project is planned to build an all-aluminum-based alloy standard workshop, with a construction area of 20,000 square meters in the first phase and 30,000 square meters in the second phase. It is planned to build all-aluminum alloy standard workshops, offices and ancillary buildings. Purchase equipment of 15 production lines, including automated intelligent welding line, automatic assembly parts production line, automatic extrusion production line, etc.

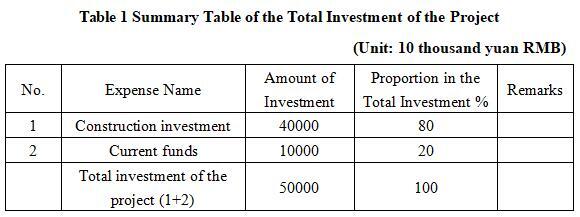

1.3. Total investment of the project and capital raising

The total investment of the project is 500 million yuan, including the construction investment of 400 million yuan

1.4 Financial analysis and social evaluation

1.4.1 Main financial indexes

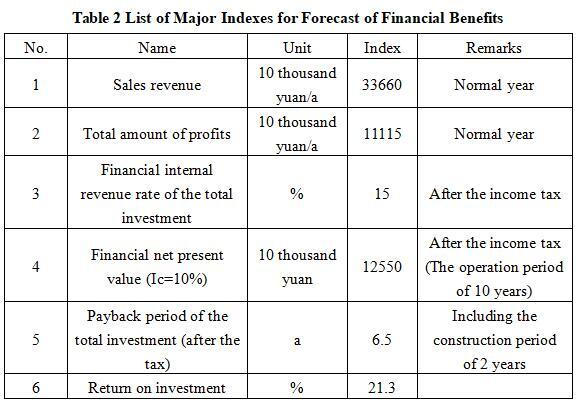

After the project reaches the production capacity, its annual sales income will be 336.6 million yuan, its profit will be 111.15 million yuan, its investment payback period will be 6.5 years (after the tax, including the construction period of 2 years) and its investment profit rate will be 21.3%.

Note: “10 thousand yuan” in the table is in RMB.

1.4.2 Social evaluation

The aluminum alloy industry will develop in the direction of intelligence, environmental protection and high-end. On the one hand, with the continuous progress of science and technology and consumers' pursuit of high-quality life, the application of aluminum alloy in high-end fields will continue to expand. On the other hand, with the improvement of global awareness of energy conservation, emission reduction and environmental protection, the aluminum alloy industry will pay more attention to green development and innovation of environmental protection technology. In addition, the introduction of intelligent production technology will also improve the production efficiency and product quality of the aluminum alloy industry, and the project construction is very necessary and has good social benefits.

1.5 Cooperative way

Sole proprietorship, joint venture and cooperation, etc.

1.6 What to be invested by the foreign party

Funds and other ways can be negotiated face to face.

1.7 Construction site of the project

Longjing City

1.8 Progress of the project

Project proposal has been prepared

2. Introduction to the Partner

2.1 Unit basic information

Name: Longjing Municipal Bureau of Commerce

Address: No. 626, Dongshan Street, Longjing City

2.2 Unit overview

Longjing City, Jilin Province is the birthplace of Korean folk culture in China, and is the area with the highest concentration of Korean people living in China and the most complete preservation of Korean folk culture. In the long course of development, the Korean nationality in China has worked hard, strived hard and prospered, nurtured a brilliant national culture, and created a unique national brand. With its unique natural resources and folk advantages, Longjing is striving to build a Chinese Korean folk culture city. Longjing City, which is located in the eastern part of Jilin Province, the southeast of Yanbian Korean Autonomous Prefecture, and at the eastern foot of Changbai Mountain, is the frontier of the Changchun-Jilin-Tumen development and opening up pilot area, an important part of the international cooperation in the Tumen River region and the integration of Yanji-Longjing-Tumen. He city covers an area of 2,208 square kilometers, with a forest coverage rate of 71.5% and a total population of 167,000, of which 110,800 are Koreans, accounting for 66.4% of the total population. It governs 5 towns, 2 townships and 1 community management committee.

With the steady advancement of the “Yanji-Longjing-Tumen” integration strategy and the in-depth implementation of the “Changchun-Jilin-Tumen Plan Outline”, the economic and social development of Longjing City is full of vitality, and its potential advantages such as ecological livability, characteristic folk customs, port location, resources and products are increasingly highlighted, and the development prospects are broad.

2.3 Contact method

Contact unit: Longjing Municipal Bureau of Commerce

Contact Person: Yang Rui

Tel: +86-15584632868

E-mail: lj_zhaoshang@163.com

Contact method of the city (prefecture) where the project is located:

Contact unit: Yanbian Prefecture Bureau of Commerce

Contact person: Li Jingyu

Tel: +86-13596515933