Carbon Fibre

Carbon Fiber Robotic Arm Construction Project of Jilin City

1. Introduction to the Project

1.1 Project background

1.1.1 Product introduction

A robotic arm is a fixed or mobile machine, typically composed of a series of interconnected or relatively sliding parts. Its working mode mainly involves linear motion along the X, Y, and Z axes to reach the target position, so as to achieve the object grasp or move, to achieve automatic control, repeatable programming, multi-degree of freedom (axis). The use of carbon fiber composite material as the overall material of the robotic arm not only makes the strength of the robotic arm higher, but also realizes the overall lightweight of the robotic arm, which plays a great role in completing tasks with high precision.

The project relies on Jilin City's advantages in the output, technology and price of the carbon fiber full product chain to build a carbon fiber robotic arm production line, and give full play to the advantages of high precision, high stability and high reliability of carbon fiber lightweight robotic arms.

1.1.2 Market prospect

1. Current development of robotic arm industry

(1) Market size

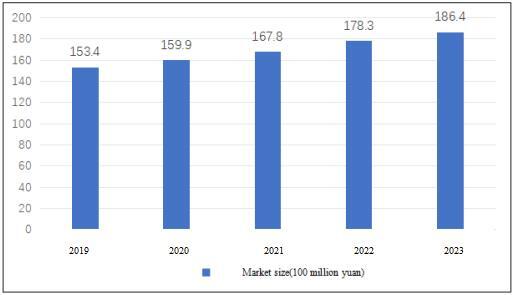

China's robotic arm market has shown a significant growth trend in recent years. Data shows that in 2022, China's robotic arm market size is close to 17.83 billion yuan, a year-on-year increase of 6.26%, and the market size will increase to 18.64 billion yuan in 2023. With the promotion of global manufacturing upgrading and automation demand, the application of robotic arms in automotive manufacturing, electronic manufacturing, logistics and warehousing will continue to expand.

Figure 1 Forecast chart of China's robotic arm market size trend from 2019 to 2024

(2) The number of patent applications for robotic arms

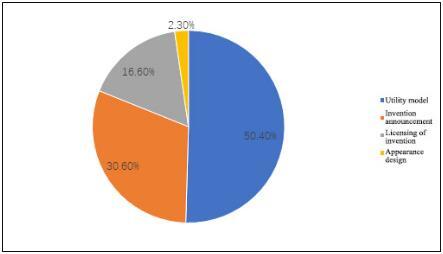

Compared with foreign countries, China's robotic arm technology started late, after 2012, gradually reached a technological breakthrough in the field of robotic arms, resulting in a rapid increase in the number of annual patent applications, marking a period of rapid development. In recent years, the number of domestic patent applications has increased year by year, from 1,955 in 2016 to 11,387 in 2020. According to incomplete statistics, at present, utility model patents account for 50.4% of the total number of robotic arm patents, invention published patents account for 30.6%, invention authorized patents account for 16.6%, and design patents account for 2.3%.

Figure 2 Patent structure of robotic arm in China

(3) Competition pattern

The competitive pattern of the domestic robotic arm industry has gradually formed. At present, the domestic robotic arm market is mainly competed by local enterprises and well-known international enterprises. Local enterprises, including ABB, Kawasaki Heavy Industries, Demage, etc., have certain advantages in technology research and development, product quality and after-sales service. Well-known international enterprises, including Yaskawa Electric of Japan and Kuka of Germany, have great advantages in technological innovation and brand influence. In addition, some emerging companies are also emerging, seeking to stand out in the market competition through technological innovation and differentiated market positioning.

2 Development prospects of robotic arm industry

With the continuous development of sensing technology, vision system and artificial intelligence, the level of intelligence and automation of robotic arms has been significantly improved. This enables the robotic arm to adapt to more complex and precise production tasks, and improves production efficiency and quality. In addition, the flexibility of the robotic arm also enables it to cope with diversified production needs and meet the needs of manufacturing transformation and upgrading. Meanwhile, it benefits from the increase of labor cost, labor shortage and the urgent need of enterprises to improve production efficiency and reduce costs. As an ideal automation equipment, robotic arm is being favored by more and more enterprises, which has great potential market demand and will bring great development potential to the industry.

3. Application of carbon fiber composite materials in robotic arms

Robotic arm has a wide range of applications in China. Firstly, in the manufacturing industry, robotic arms can be applied to industries such as automotive manufacturing, electronic manufacturing, and metal processing to achieve automation and flexibility of production lines. Secondly, in the field of logistics, the robotic arm can be applied to warehousing, sorting, loading and unloading and other links to improve logistics efficiency and accuracy. In addition, the robotic arm can also be applied to medical, agriculture, aerospace and other fields to provide intelligent solutions for all walks of life.

In recent years, with the continuous development of robot technology in China, the improvement of robot performance such as high speed, high precision and high load weight ratio has attracted the attention of industry and aerospace fields. Due to the increase of the flexible effect of joint and connecting rod during the movement of the manipulator arm of the traditional metal robot, the structure is deformed and the precision of task execution is reduced. Therefore, the structural flexibility characteristics of the robotic arm must be considered to achieve high-precision and effective control of the flexible arm, and the overall material characteristics of the robotic arm must also be considered. Therefore, choosing the right material for the robotic arm is crucial.

Since its birth, carbon fiber has been known for its high strength, corrosion resistance, impact resistance and light weight. The carbon fiber robotic arm is the lightest of the different materials of the robotic arm, which not only reduces the weight of the robotic arm, but also ensures that the robotic arm can better achieve static and dynamic performance. In addition to lightweight, the mechanical properties of the carbon fiber robotic arm are also very excellent, with good load bearing performance and no fracture and strain. Carbon fiber robotic arm has good fatigue resistance, can maintain good toughness and elasticity in long-term operation, compared with traditional metal materials, there will be no creep phenomenon, can maintain the working accuracy of the robotic arm, ensure product quality, and reduce rework rate. Therefore, carbon fiber robotic arm has a wide range of application prospects in the high-end manufacturing field.

1.1.3 Technical analysis

This project optimizes the laying design of carbon fiber prepreg through the molding process, which can achieve the thermal deformation effect of approximately "0", which can significantly reduce the deformation rate of carbon fiber robotic arm and improve the overall performance.

1.1.4 Advantageous conditions of project construction

(1) Policy advantages

The Implementation Opinions of Seven Departments of the Ministry of Industry and Information Technology on Promoting Future Industrial Innovation and Development proposes to break through core technologies such as robot high-torque density servo motors, high-dynamic motion planning and control, bionic perception and cognition, intelligent dexterity hands, and electronic skin, focusing on the development and application of products in intelligent manufacturing, home services, special environmental operations and other fields.

The "Robot +" Application Action Implementation Plan of the Ministry of Industry and Information Technology proposes that by 2025, the density of robots in the manufacturing industry will double compared with that in 2020, and the application depth and breadth of service robots and special robots industries will be significantly improved.

The seven departments of the Ministry of Industry and Information Technology and the Implementation Plan for Promoting Equipment Renewal in the Industrial Field propose to focus on the transformation of production operations, warehousing and logistics, quality control and other links, and promote the renewal of general intelligent manufacturing equipment such as CNC machine tools and basic manufacturing equipment, additive manufacturing equipment, industrial robot industrial control equipment, intelligent logistics equipment, sensing and testing equipment. The electric bicycle industry updates automatic welding robots, automatic spraying and drying equipment, electric or pneumatic assembly equipment, insulation voltage testers, cyclic charge and discharge testers, etc.

The Action Plan for Carbon Peak before 2030 proposes to accelerate the research and development of basic materials such as carbon fiber, aerogel, and special steel, and fill in the shortcomings of key parts, components, and software.

The 14th Five-Year Plan of the National Economic and Social Development of the People's Republic of China and the Outline of the 2035 Vision Goals propose to strengthen the research and development and application of high-performance fibers such as carbon fiber and their composites, which provides a good policy environment for the technological progress of the carbon fiber industry in the future.

Jilin Provincial Government issued the Several Measures on Promoting the High-quality Development of Carbon Fiber and Composite Materials Industry (version 2.0) (JLZBF[2023] No.8), from increasing the cultivation of enterprise main body, promoting the development of industrial clusters, highlighting the leadership of scientific and technological innovation and other six aspects to support.

Jilin City issued the Preferential Policy for the Introduction of Carbon Fiber Composite Materials and Products Project in Jilin City, giving policy support to the whole industrial chain of carbon fiber from the aspects of prioritizing land supply, raw material supply, supporting docking cooperation, investment awards and subsidies, and talent introduction.

(2) Resource advantages

CNPC Jilin Petrochemical Company Acrylonitrile Plant is currently one of the large acrylonitrile production bases in China, with a commercial volume of 300,000 tons/year. After the transformation and upgrading of the 1.2 million tons per year ethylene project put into operation, it is expected to increase the commercial volume of acrylonitrile by 260,000 tons, fully meeting the production needs of carbon fiber. And the pipeline transportation between Jilin Chemical Fiber Group helps to reduce raw material procurement costs. At the same time, the production capacity of carbon fiber precursor and carbon fiber in the region rank first in China, with the most complete specifications and steadily improving quality. Jilin Chemical Fiber Group can provide raw materials for major customers to invest in carbon fiber enterprises in the region, and the production line can be adjusted according to the individual needs of different products to meet the market demand of different composite fields.

Jilin City has abundant hydropower, developed thermal power and sufficient power supply. At present, the average price of large industrial is 0.6 yuan per degree, after the completion of “Jilin Wind and Solar Three Gorges” project, Jilin Economic Development Zone carbon fiber industry will be a large number of green electricity produced in Songyuan, Baicheng and other places, the price can be controlled within the average 0.4 yuan per degree, further reducing the cost of enterprise electricity. The surface water resources are 7.855 billion cubic meters, and the groundwater resources are 1.842 billion cubic meters. At the end of the year, the total storage capacity of large and medium-sized reservoirs in the city was 11.35 billion cubic meters.

(3) Industrial advantages

Jilin City is the cradle of China's carbon fiber industry, engaged in carbon fiber research and production since the 1970s. In January 2010, the base was identified by the Ministry of Science and Technology as the only "national carbon fiber high-tech industrialization base" in China. In March 2020, it was approved by the Ministry of Industry and Information Technology as the "national new industrialization demonstration base of carbon fiber and composite materials"; In September 2021, it was awarded the "R&D and production base of large tow carbon fiber and products" by China Chemical Fiber Industry Association. At present, it has formed the most complete carbon fiber industrial chain in China from "acrylonitrile - acrylonitrile based precursor - carbon filament - downstream products", with the world's first filament production capacity, the country's first carbon filament production capacity and the world's second. In the metallurgical industry, with the province's largest metallurgical base, two national metallurgical technology centers, Jianlong Group has become the province's first steel production enterprises.

There are Jilin Chemical Fiber Group, Carbon Valley Carbon Fiber Co., LTD., Guoxing Carbon Fiber Co., LTD., Guoxing Composite Co., LTD., Jiyan High-tech Fiber Co., LTD and a number of well-known domestic carbon fiber backbone enterprises in Jilin City, with the raw wire production capacity of 160,000 tons, carbon fiber production capacity of 49,000 tons, the specifications cover 1K-50K, the small tow products stable performance of T700, and the large tow products of the world's best quality; The first phase of the T800 and T1000 high-performance carbon fiber projects of Carbon Valley Carbon Fiber Company has started trial operation; Woven fabrics, prepregs, pultruded plates, carbon fiber felt and other downstream composites and products have formed large-scale production capacity.

Jilin Economic and Technological Development Zone raised funds from various sources to build and construct the specialized parks such as China Jilin National Carbon Fiber Industrial Park and China Jilin High Performance Fiber Composite New Material Industrial Park, focusing on enhancing the industrial carrying capacity. China Carbon Valley Carbon/Carbon Composite Materials Industrial Park, Carbon Fiber Industrial Park, Carbon Fiber Products Industrial Park, Carbon Fiber Raw and Auxiliary Materials Industrial Park, covering a total area of 185 hectares, has been dedicated to provide customized services for carbon fiber and its downstream application projects.

(4) Talent advantages

There are 9 universities and colleges in Jilin City. There are nearly 100,000 full-time students in the university, and more than 30,000 graduates from colleges and universities every year. The city has about 61,000 professional and technical personnel and 496,000 skilled personnel, including 144000 high skilled talents.

Jilin City is the cradle of new China's chemical industry and the training and output base of carbon fiber industry talents. Relying on the training and transportation of colleges and universities in the region, especially the experience of large and medium-sized state-owned enterprises such as CNPC Jilin Petrochemical and Chemical Fiber Group, Jilin City has cultivated a large number of high-quality professional and technical talents and industrial workers in chemical industry and chemical fiber production, with a significantly lower labor cost than that of developed areas.

(5) Location advantages

Jilin City is located in the core area of Changchun-Jilin-Tumen in Northeast Asia, adjacent to Yanbian seas to the east, Harbin, Changchun, Shenyang and Dalian to the west, the expressway to Dandong to the south, and Sanjiang Plain to the north. The road transportation is convenient, with distances of 64.5 kilometers from Longjia Airport, 117 kilometers from Changchun, 397 kilometers from Shenyang, 355 kilometers from Harbin, 780 kilometers from Dalian Port, and 1020 kilometers from Tianjin Port. It can connect with the Beijing Tianjin Hebei region, radiate to Northeast Asia, and has obvious geographical development advantages. The expressway forms a "radiating rill" road network, while the railway forms a cross shaped support. It has intercity railways such as Changchun-Hunchun, Changchun-Tumen, Jilin-Shulan, and Shenyang-Jinlin, as well as dedicated and connecting lines for railways such as Jiujiang line, Jiuqi line, and Xiha line. The railway in Jilin region sent 26.706 million tons of freight and received 28.17 million tons of freight.

Jilin Economic and Technological Development Zone is located in the northeast transportation hub, only 60 kilometers away from Changchun Longjia International Airport; The main arterial highway Changchun-Hunchun Expressway has an exit in Jilin Economic Development Zone; There are two intermediate railway stations, the Shuangji Railway Station has been put into operation; The Ertaizi Airport is ready to resume operation. In addition, there is the only B-type bonded logistics center Jilin Bonded Logistics Center in Jilin province.

1.2 Contents and scale of project construction

1.2.1 Scale of project construction

After the completion of the project, the annual output of robotic arms will be 5,000 sets.

1.2.2 Contents of project construction

The project covers an area of 10000 square meters with a building area of 12000 square meters. It will purchase carbon fiber robotic arm production line equipment and construct supporting facilities such as production workshops, warehouses, logistics centers, and comprehensive buildings.

1.3 Total investment of the project and capital raising

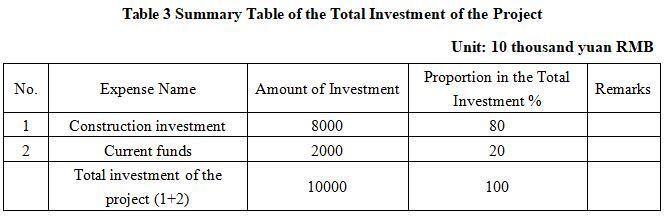

1.3.1 Total investment of the project

The total investment of this project is 100 million yuan, including construction investment of 80 million yuan and working capital of 20 million yuan.

1.3.2 Fundraising

Fundraising by enterprises independently.

1.4 Financial analysis and social evaluation

1.4.1 Main financial indexes

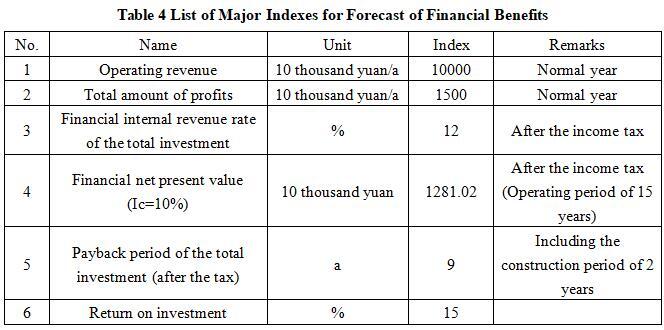

After the project reaches the production capacity, its annual sales income will be 100 million yuan, its profit will be 15 million yuan, its investment payback period will be 9 years (after the tax, including the construction period of 2 years) and its investment profit rate will be 15%.

Note: “10 thousand yuan” in the table is in RMB.

1.4.2 Social evaluation

The construction of the project is conducive to improving the production technology of China's domestic robotic arm and enhancing the competitiveness and influence of domestic robotic arm in the international market. In the future, with the continuous development of the manufacturing industry and the continuous improvement of the level of automation, China's robotic arm industry will continue to maintain a rapid development trend, providing strong support for the transformation and upgrading of the global manufacturing industry and high-quality development.

1.5 Cooperative way

Joint venture, cooperation, sole proprietorship, other ways can be discussed offline.

1.6 What to be invested by the foreign party

Funds, other means can be discussed offline.

1.7 Construction site of the project

Jilin Economic and Technological Development Zone

1.8 Progress of the project

This project is in the stage of external investment promotion.

2. Introduction to the Partner

2.1 Basic information

Name: Jilin Economic and Technological Development Zone Management Committee

Address: No. 499 Jiujiang Road, Jiuzhan Street, Jilin City

2.2 Overview

Jilin Economic and Technological Development Zone is located in the northwest suburb of Jilin City. It was established in 1998 and promoted to the national economic and technological development zone in 2010. It covers an administrative area of 93 square kilometers and a built-up area of 20.4 square kilometers. The leading industries include new materials, fine chemicals, biology, medicine, etc. It is a national high-tech industrialization base of carbon fiber recognized by the Ministry of Science and Technology, a national science and technology enterprise incubator of new chemical materials based on carbon fiber, a demonstration base of new industrialization of carbon fiber and composite materials recognized by the Ministry of Industry and Information Technology, a national patent industrialization pilot base recognized by the Intellectual Property Office, the first batch of national general aviation industry comprehensive demonstration zones approved by the National Development and Reform Commission, a research and production base for large fiber bundles of carbon fiber and products recognized by the Chemical Fiber Association, and the most competitive fine chemical industry cluster in Northeast China.

The power supply, heating, gas supply, water supply, drainage, communication, sewage treatment and other facilities in the area are complete, with complete functions such as research and development testing and enterprise incubation. In the development of the new area, specialized parks such as china Jilin national carbon fiber industrial park and high-performance fiber composite new material industrial park have been built to enhance the industrial carrying capacity. In this year, a new carbon fiber "zero carbon" products industrial park has been planned to further enhance the comprehensive supporting functions and industrial carrying capacity of the park, which can provide complete public works and factor guarantee services for projects entering the park.

2.3 Contact method

Postal code: 132000

Contact person: Sun Zhenda

Tel: +86-432-66490969 +86-13944245509

E-mail: jkkj07@163.com

Contact method of the city (prefecture) where the project is located:

Contact unit: Jilin City Cooperation and Exchange Office investment promotion Service Center

Contact person: Wang Yanchao

Tel: +86-15843218881