Petrochemical

Aviation Fuel Preparation and High-value Chemical Co-production from Straw Biomass Project of Changchun City

1. Introduction to the Project

1.1 Project background

1.1.1 Product introduction

The technology of preparing aviation fuel from straws has innovatively introduced a unique new process for the synthesis of aviation bio-fuel by aqueous-phase catalysis of biomass. This process is known for its advantages of short reaction steps, high efficiency, and comprehensive utilization of all components. As a highly innovative technology in the field of aviation bio-fuel, it has become a key technological reserve in the national energy strategy and has profound social significance.

By now, this technology has become a revolutionary technology in the comprehensive utilization of agricultural and forestry fiber resources in China, opening up new avenues for the high-value utilization of straw-based agricultural and forestry wastes. More critically, the project is in line with the national energy development strategy and belongs to the key industry category encouraged and supported by the state, with significant national strategic significance.

1.1.2 Market prospect

(1) Current market situation

The production technology of biomass aviation fuel covers multiple links such as biomass conversion, catalytic cracking, and synthesis. Firstly, through the process of biomass conversion, biomass raw materials are converted into combustible gases or liquid fuels. Next, catalytic cracking technology is used to further convert these raw materials to prepare fuel. Ultimately, combustible gases or liquid fuels are converted into biomass aviation fuel that meets aviation fuel standards through synthesis technology.

Compared to traditional petroleum fuel, biomass aviation fuel provides strong power during flight, with no difference in effectiveness compared to traditional aviation fuel, while significantly reducing the overall carbon intensity of the fuel. This indicates that, the use of biomass aviation fuel can effectively reduce the impact of the aviation industry on global climate change. In addition, the production process of biomass aviation fuel can help reduce reliance on petroleum resources, lower energy consumption, and reduce air pollution emissions in the aviation industry, improve air quality, and reduce potential harm to human health.

The annual usage of aviation fuel in China has exceeded 33 million tons and is increasing at an average annual rate of 10%. It is expected that by 2025, the maximum usage of aviation fuel will reach 50 million tons. According to the “carbon neutrality” goal, carbon dioxide (CO2) emissions need to reach the peak before 2030, and carbon neutrality needs to be achieved before 2060. According to the national dual-carbon policy, the carbon emission reduction task of the aviation industry is particularly urgent. At present, there are two main ways to achieve carbon emission reduction in aviation: one is through the development of new engines, fuselage optimization, air traffic control optimization and other fuselage modification technologies, and the other is through mixed combustion of aviation bio-fuel to achieve carbon emission reduction. However, limited by the technological monopoly of the Western aviation manufacturing industry, it is more difficult to implement the former, while the latter is a key part of China’s energy strategic planning.

In 2023, the aviation bio-fuel market size reached 519.519 billion yuan RMB in the globe, and reached 163.7 billion yuan in China It is expected that by 2029, the global aviation bio-fuel market size will reach 761.472 billion yuan, with an expected compound annual growth rate of 6.57% during this period.

The Biomass Energy Industry Promotion Association predicts that, the utilization of biomass energy in China will increase from less than 500 million tons in 2023 to 700 million tons in 2030, and further increase to 1.7 billion tons by 2060. This reflects an important direction for the utilization of aviation bio-fuels as biomass energy, and their utilization will also increase accordingly.

Compared with traditional aviation kerosene, aviation bio-fuel can achieve CO2 emission reduction from 55% to 92%. This significant emission reduction effect makes aviation bio-fuel play a crucial role in addressing climate change and reducing the environmental impact of the aviation industry.

Given the huge demand for aviation kerosene in China and the difficulty of replacement by alternative energy sources such as hydrogen and electricity, the aviation bio-fuel that is mainly composed of corn straws can achieve effective replacement, thereby ensuring energy security. Aviation bio-fuel plays an irreplaceable role in ensuring aviation energy security and achieving aviation carbon emission reduction.

(2) Project prospect

After continuous experiments and analysis, China has successfully developed an innovative three-element separation technology using solvent method, achieving step-by-step separation of hemicellulose, cellulose, and lignin. Based on the structural differences of these three components, a new route for aviation fuel extraction technology has been explored. In this technical route, the levulinic acid produced from hydrolysis of cellulose and the furfural obtained from gas stripping of hemicellulose can be converted into sustainable aviation bio-fuel through condensation and refining. Furfural, like lignin, can also be used as a raw material for specialty fuels. The use of three-element separation technology to extract aviation bio-fuel results in extremely high carbon utilization efficiency and little waste of raw materials throughout the entire process. The oil components produced by this technological route are extremely similar to petroleum-based aviation fuel, with almost identical physical and chemical properties. In addition, the direct cost of this technology is only 40% of the currently popular bio-fuels of animal and vegetable fats and oils. The new path of oil refining from straws has completely independent intellectual property rights, and has better carbon emission reduction effect. It can be said that this new sustainable bio-fuel is an ideal alternative to aviation fuel.

It is predicted that the consumption of aviation kerosene in China will reach 60 million tons by 2030. If sustainable aviation bio-fuel is blended at a ratio of 10%, the demand for sustainable aviation bio-fuel will reach 6 million tons, with an output value of up to 120 billion yuan, having a very broad market prospect. The new era of sustainable aviation bio-fuel is to come, and we look forward to that it can become an important force in promoting the sustainable development of the global aviation industry.

In this context, the development of the technology of preparing aviation fuel from biomass is particularly important. Preparing aviation fuel from biomass, i.e., converting biomass resources (such as corn straws and saw-dusts) into aviation fuel, can not only reduce the reliance on traditional fossil fuels but also effectively lower carbon emissions from aviation transportation. By now, China has made certain progress in the field of preparing aviation fuel from biomass, but compared with the international advanced level, there are still technical bottlenecks and cost issues.

In order to promote further development of the technology of preparing aviation fuel from biomass, the Chinese government and related enterprises are increasing investment in research and development, optimizing production process, and improving conversion efficiency. Meanwhile, through policy guidance and market incentives, more scientific research institutions and enterprises are encouraged to participate in the development and application of biomass energy. In addition, China is actively exploring international cooperation, introducing advanced foreign technologies and management experience, in order to achieve leapfrog development in the field of preparing aviation fuel from biomass.

By now, the global aviation industry has gradually begun to adopt biomass aviation fuel to reduce carbon emission. In the future, with the continuous advancement of technology and the reduction of production cost, biomass aviation fuel will become more popular and become one of the main means for the aviation industry to reduce carbon emission.

Biomass aviation fuel is a green and environment-friendly choice that can not only reduce carbon emissions, but also reduce reliance on petroleum resources and improve the air quality.

In the future, with the continuous maturity of technology and further cost reduction, preparing aviation fuel from biomass is expected to become an important part of the aviation fuel market. This will not only help China achieve its carbon emission reduction target in the aviation industry, but also provide Chinese solutions and Chinese wisdom for the sustainable development of the global aviation industry. There is a broad application prospect for biomass aviation fuel.

1.1.3 Technical analysis

At present, there are 5 technical routes internationally. Firstly, extraction from traditional petrochemical oil. Secondly, extraction from oils and fats (swill-cooked dirty oil) upon hydrogenation. Thirdly, Fischer-Tropsch synthesis (biological waste + synthetic gas). Fourthly, oligomerization of alcohol and olefin (carbohydrate + hydrogen). Fifthly, the technical route of lignocellulose (lignocellulose - hydropyrolysis process - recarburization and isomerization - hydrodeoxygenation - kerosene).

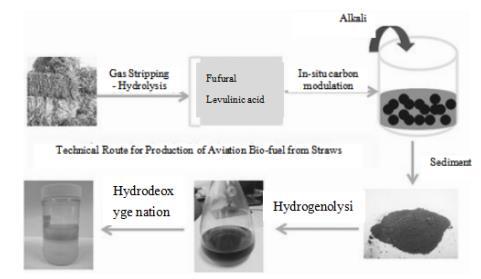

Technical route for preparing aviation fuel from lignocellulosic biomass:

Raw materials (corn straw, corn cob) - acid soaking - reaction tank - gas stripping, hydrolysis - furfural solution - catalysis in reaction tank - condensation and filtration - solid-liquid separation - condensation product (project product, aviation kerosene precursor) - catalytic reaction - hydrodeoxygenation - aviation oil product.

Figure 1 Technical Route for Production of Aviation Bio-fuel from Straws

The use of straw as raw material has a significant emission reduction effect throughout the entire industrial chain. The technology can not only control non-point source pollution from the source, but also achieve the ‘dual reduction' goal of low-carbon emission reduction in the use terminal.

1.1.4 Advantageous conditions of project construction

(1) Policy advantages

In the China Renewable Energy Development Report, it was pointed out that we should actively develop biomass energy clean heating, accelerate the development of biomass natural gas, and vigorously develop non-grain biomass liquid fuels.

In the Action Plan for Promoting Large-scale Equipment Renewal and Trade-in of Old Consumer Goods issued by the State Council in 2024, it was proposed to actively and orderly develop biomass liquid fuels mainly composed of waste oil and non-grain biomass, vigorously support the development of new energy powered ships, improve the supporting infrastructure and standard specifications for new energy powered ships, and gradually expand the application scope of ships with new energy such as bio-diesel power.

In the notice by the National Energy Administration of issuing the Action Plan to Standardize Carbon Peaking and Carbon Neutrality in Energy, it was pointed out that we should promote the conversion and utilization of biomass energy (including biomass power generation, bio-gas production, cellulose fuel ethanol, bio-diesel, bio-aviation kerosene, bio-briquette fuel, etc.).

(2) Industrial advantages

Yushu City has abundant corn resources and is located on the world's golden corn belt. It is rich in corn, soybeans, rice, and other crops, and its total grain output has ranked first among counties and cities in China for many years. It is known as the “No. 1 Granary in the World” and has been rated as a “Good Corn Production Base in China” by the state. Its annual grain output is 7 billion jin (equaling to 3.5 billion kilograms).

(3) Location advantages

The Wukeshu Economic Development Zone is located in Yushu, Changchun City, Jilin Province, and specifically, it is 50 meters west of Yushu-Taolaizhao Highway. The transportation in Wukeshu Economic Development Zone is very convenient, with railways, highways, and waterways extending in all directions. Specifically, the Changchun-Yushu and Harbin-Yushu Railways pass through the zone, with two stations: Wukeshu Station and Liujia Station. Highways: Yushu-Taolaizhao first-class highway runs through the whole territory, connecting with National Highway 102, and the urban area is only 16 kilometers away from Beijing-Harbin Expressway. Waterway: The Second Songhua River flows along the border, and water transportation can go up to Jilin City, down to Harbin, until the border port. Aviation: Yushu City is approximately 166 kilometers away from Longjia Airport, and it only takes about two hours to drive there, providing great convenience for the rapid transportation of goods and the convenient travel of personnel. In addition, as an important aviation hub in China, Longjia Airport has abundant domestic and international route resources, further expanding the connection channels between Wukeshu Economic Development Zone with domestic and foreign markets, which is conducive to attracting foreign investment, promoting trade exchanges, and driving regional economic development. These geographical locations make the Development Zone not only have convenient transportation, but also easy to connect and communicate with surrounding cities.

(4) Talent advantages

Changchun is a well-known high intelligence intensive area in China, with more than ten key universities such as Jilin University, Northeast Normal University, and Changchun University of Science and Technology. It also has national and provincial (ministerial) scientific research institutions such as the Chinese Academy of Sciences, Changchun Branch, Changchun Institute of Optics, Fine Mechanics and Physics, Changchun Institute of Applied Chemistry, as well as scientific research institutions such as design institutes, computing and testing centers, and several key national open laboratories in Changchun. Changchun City has abundant human resources and price advantages. Higher education institutions and research institutions such as Jilin University, Northeast Normal University, Changchun University of Traditional Chinese Medicine, Changchun Institute of Optics, Fine Mechanics and Physics, and Changchun Institute of Applied Chemistry can provide senior management and technical personnel for the implementation of the project.

1.2 Contents and scale of project construction

The project covers an area of 200,000 ㎡ and a construction area of 100,000 ㎡. It has an annual processing capacity of 60,000 tons of aviation kerosene precursor, 500,000 tons of biomass such as corn straws and corn cobs, co-production of 2.55 million kilograms of levulinic acid, and 400,000 tons of organic fertilizer.

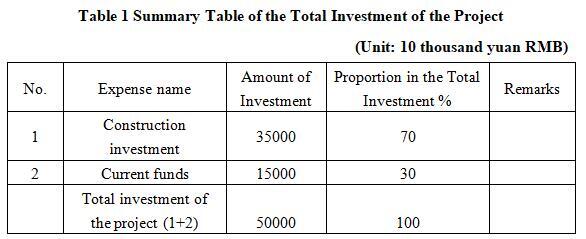

1.3 Total investment of the project and capital raising

The total investment of the project is 500 million yuan, including the construction investment of 350 million yuan.

1.4 Financial analysis and social evaluation

1.4.1 Main financial indexes

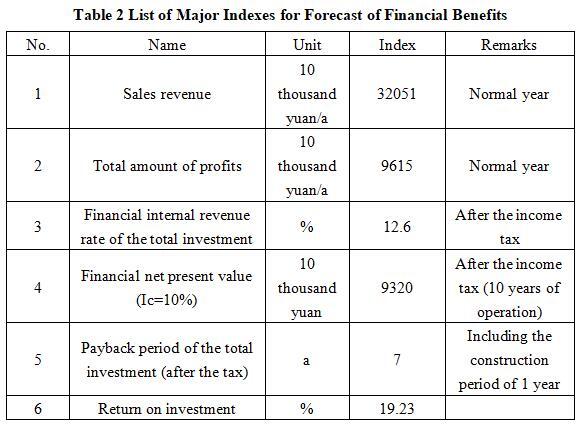

After the project reaches the production capacity, its annual sales income will be 320.51 million yuan, its profit will be 96.15 million yuan, its investment payback period will be 7 years (after the tax, including the construction period of 1 year) and its investment profit rate will be 19.23%.

Note: “10 thousand yuan” in the table is in RMB

1.4.2 Social evaluation

Energy-saving benefits: Biomass energy is a low-cost and stable source of clean energy. Using biomass energy to replace fossil energy can avoid the risk of price fluctuation of fossil energy and achieve structural energy-saving benefits.

Consumption reduction benefits: The greenhouse gas emissions from biomass energy combustion are equivalent to the CO2 absorbed during its growth process, and it replaces fossil energy, achieving “zero” emission. In addition, biomass fuel has extremely low sulfur, nitrogen, and ash content, and does not require desulfurization or denitrification measures during combustion to meet national environment-friendly requirements. There is no generation of “three wastes” (wastewater, exhaust gas, and waste residue) during production and use, achieving clean production.

Environment-friendly benefits: There is no generation of “three wastes” (wastewater, exhaust gas, and waste residue) during production and use of biomass energy, and there is no pollution such as scattered dust during storage and transportation. It meets the requirements of clean fuel indicators and does not require high investment and operating costs for desulfurization and denitrification equipment.

Economic benefits: The production and use of aviation bio-fuel can reduce reliance on imported oil and lower the energy cost. In addition, high-value chemicals such as levulinic acid can be co-produced during production of aviation bio-fuel, further increasing the economic benefits.

Social employment: The construction and operation of the project of preparing aviation fuel from biomass require a large amount of human resources, including raw material collection, processing, transportation, and other links, thereby creating a large number of employment opportunities and promoting local economic development.

1.5 Cooperative way

Sole proprietorship, joint venture and cooperation.

1.6 What to be invested by the foreign party

Funds, other ways can be discussed in person.

1.7 Construction site of the project

Changchun Wukeshu Economic Development Zone (31 kilometers away from Yushu-Taolaizhao Highway)

1.8 Progress of the project

The project proposal has been prepared

2. Introduction to the Partner

2.1 Basic information of unit

Name: Changchun Wukeshu Economic Development Zone

Address: Changchun Wukeshu Economic Development Zone (31 kilometers away from Yushu-Taolaizhao Highway)

2.2 Overview of unit

Changchun Wukeshu Economic Development Zone is a provincial-level development zone approved by Jilin Provincial Government on July 15, 2003, and it is located 3 kilometers west of Yushu City. The area covers 804 square kilometers, with a planned core area of 45.55 square kilometers and a total population of 319,000.

In recent years, the park has successively introduced many well-known domestic and foreign enterprises such as COFCO Bio-chemical, SDIC Biotech, CP Group (Thailand), Centrient (USA), Jindong Group, Beijing Capital Agribusiness Group, Dalian Shide, Sihai Group, Tongwei Company, Dalian Huinon, Jilin Dadi Environmental Protection, Jilin Haichuan, and Fenglin Food, etc. So far, more than 300 enterprises of various types have entered and been stationed in the development zone, including 31 enterprises above designated size. There are 5 Fortune 500 companies and 5 domestic Fortune 500 companies. The enterprises stationed in the zone can provide employment opportunities for 25,000 laborers annually. It has initially formed characteristic industrial parks such as the corn bio-chemical industrial park represented by COFCO Bio-chemical Energy (Yushu) Co., Ltd.; the bio-pharmaceutical industry park represented by Centrient Bio-chemical Intermediates (Changchun) Co., Ltd; the livestock and poultry product processing industrial park represented by CP Group (Thailand); the liquor industry demonstration park represented by Yushuqian Liquor Industry and 138 liquor companies; and the “entrepreneurship and innovation” industrial park represented by Stkailun Entrepreneurship and Innovation Base. The infrastructure construction in the Wukeshu Chemical Industrial Park is becoming increasingly perfect.

The Wukeshu Development Zone has been successively rated as the “National Agricultural Product Processing Industry Demonstration Base” by the Ministry of Agriculture, “Provincial Agricultural Product Processing Industry Demonstration Zone” by the Jilin Provincial People’s Government, and “National Top 100 Scientific Development Demonstration Park” by the National Development and Reform Commission.

2.3 Contact method

Contact person: Li Lingang

Tel: +86-431-83060888

E-mail: yshzjl5021@163.com

Contact method of the city (prefecture) where the project is located:

Contact unit: Changchun Cooperation and Exchange Office

Contact person: Zhang Junjie

Tel: +86-15704317930

Fax: +86-431-82700590

E-mail: xmc82763933@163.com