Petrochemical

15,000 Tons/Year Antioxidant DSP6168 Project of Jilin City

1. Introduction to the Project

1.1 Project background

1.1.1 Product introduction

The project relies on the foundation of Jilin’s petrochemical industry and plans to produce DSP6168 series antioxidants, which will be applied to materials such as polyethylene, polypropylene, polystyrene, polycarbonate, and polyamide to enhance product performance and increase the competitiveness of Jilin’s chemical industry.

DSP6168 is a series of high-performance composite antioxidants that integrates the functions of hindered phenolic main antioxidants and sulfur phosphorus auxiliary antioxidants, filling the gap in the domestic industry. The development of this product conforms to market trends, closely follows international trends, and can replace imported specialized, new, and high-performance antioxidant varieties.

1.1.2 Market prospect

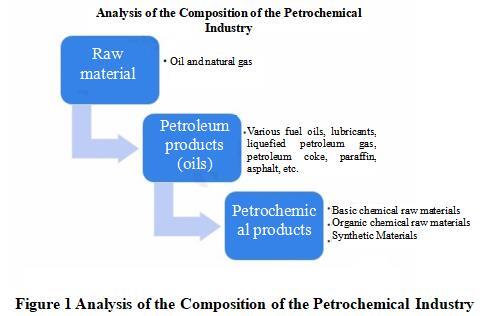

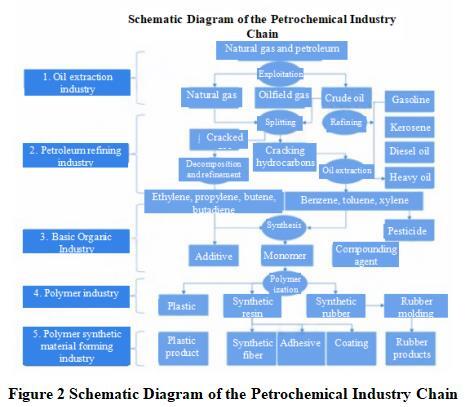

Petrochemical industry refers to the processing industry that uses petroleum and natural gas as raw materials to produce petroleum products and petrochemical products.

Petrochemical products are obtained by further chemical processing of raw oil provided by the refining process. The first step in producing petrochemical products is to crack the raw materials oil and gas (such as propane, gasoline, diesel, etc.) to produce basic chemical raw materials represented by ethylene, propylene, butadiene, benzene, toluene, and xylene. The second step is to produce various organic chemical raw materials (about 200 types) and synthetic materials (plastics, synthetic fibers, synthetic rubber) using basic chemical raw materials. The production of both products falls within the scope of petrochemicals.

The upstream of the petrochemical industry mainly includes the petroleum extraction and refining industry, including oil and gas extraction and transportation, refining, and petrochemical product processing and manufacturing processes. The midstream is the basic organic and polymer industry, and the downstream industry provides supporting and services for agriculture, energy, transportation, machinery, electronics, textiles, light industry, construction, building materials, and other industrial and agricultural sectors as well as people’s daily lives. It should be noted that in the petrochemical production process, chemical catalysts are added to promote refining and decomposition processes to improve processing efficiency.

China’s petrochemical industry has gone through four stages of continuous exploration and development: recovery and development stage, historic transformation stage, new rise stage, and new development stage. China has become the world’s second largest producer and consumer of petroleum and chemicals. The petrochemical industry is an important pillar industry of the national economy. In recent years, China has formulated relevant policies for the development and construction of the petrochemical industry, providing guarantees for the rapid development of China’s petrochemical industry.

Carbon neutrality may bring disruptive changes and opportunities to the petrochemical industry. To achieve carbon peak and carbon neutrality goals, industries such as steel, electricity, petrochemicals, and coal are accelerating their transformation. Many listed companies have developed carbon peak and carbon neutrality roadmaps. The goal of carbon peaking and carbon neutrality has brought significant pressure to the green and low-carbon transformation of petrochemical enterprises. However, in the process of transformation, it also nurtures new development opportunities, including opportunities to develop new energy, new materials, and new business models, promoting the shift from fossil energy dominated energy structure, industrial structure, and economic structure to renewable energy dominated. This process drives the industry to reconstruct its industrial chain and value chain, and requires more reliance on technological innovation to fundamentally change the structural form of the petrochemical industry in achieving carbon reduction targets.

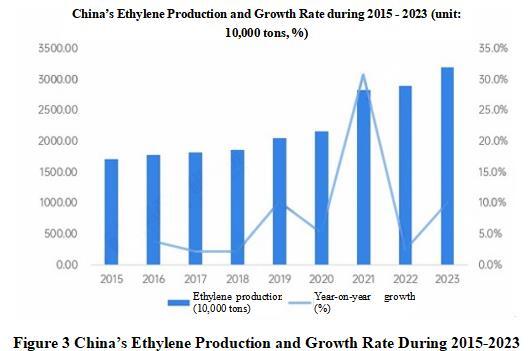

According to the latest data from the National Bureau of Statistics, China’s ethylene production in 2022 was 28.975 million tons, with a year-on-year increase of 2.5%; In 2023, the ethylene production was 31.898 million tons, with a year-on-year increase of 10.1%.

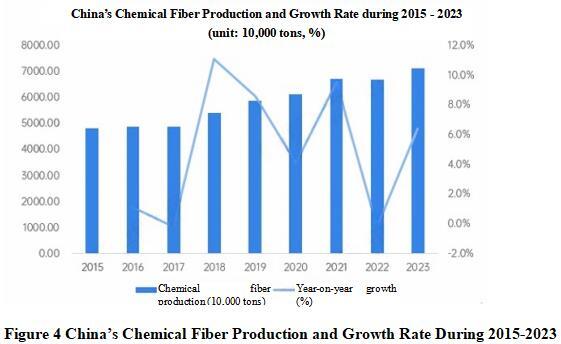

According to the latest data from the National Bureau of Statistics, the overall production of chemical fibers in China has shown an upward trend during 2015- 2023. In 2023, China’s chemical fiber production reached 71.27 million tons, with a year-on-year increase of 6.4%.

Currently, China’s petrochemical industry is undergoing industrial restructuring, with enterprises utilizing both international and domestic markets and resources to promote the adjustment and optimization of industrial structure, including economic structure. In recent years, the regional structure of China’s petrochemical industry has been continuously improving, outdated production capacity has been eliminated, innovation capabilities have been continuously enhanced, and the level of international operation has also been continuously improved. In terms of the number of enterprises in 2023, the top three are Shandong Province, Shaanxi Province, and Guangdong Province.

According to the 14th Five-Year Plan Guidelines for Petrochemical and Chemical Industry released by the China Petroleum and Chemical Industry Federation, the main task of the 14th Five-Year Plan is to promote the modernization of China’s petrochemical industry. Increase the richness and high-end level of chemical new material products, and open up the path of “improve weak links” and “filling gaps”; Intensify efforts to provide customized services for product applications.

With the recovery of the global economy and the rapid development of the Chinese economy, it is expected that the scale of China’s petrochemical market will continue to expand in the next five years. Meanwhile, the promotion of carbon peak and carbon neutrality goals will accelerate the transformation of the petrochemical industry towards green and low-carbon. Green and low-carbon transformation will nurture new development opportunities. Enterprises need to adopt more environmentally friendly production processes and technologies, reduce pollutant emissions, and improve resource utilization efficiency, which will also bring new development opportunities to the industry.

(2) Analysis of the Current Situation of Polyethylene Industry

During 2020- 2024, the global polyethylene production capacity continued to expand, with a compound annual growth rate of 4.49%. By the end of 2024, the global new production capacity reached 3.45 million tons, with a total production capacity exceeding 151,033,400 tons, with a year-on-year increase of 2.34%. The newly added production capacity is mainly concentrated in Northeast Asia, North America and Southeast Asia, with Northeast Asia accounting for 76.81% of the total. China is the main force behind the expansion in this region. The total production capacity of polyethylene in China reached 33.958 million tons in 2024, with a cumulative new production increase of 14.9 million tons within Five-Years, and a compound growth rate of 12.25%.

In terms of supply and demand, the supply-demand contradiction in the domestic HDPE market will intensify in 2024. The HDPE production significantly increased in the fourth quarter, leading to increased supply pressure. The total HDPE production in December reached 1.2127 million tons, an increase of nearly 17.58% compared with November. Despite the increase in supply, downstream demand is weak, operating rates have decreased, finished product inventory has accumulated significantly, and buyers’ purchasing willingness is low. The overall supply pressure in the market has increased, and price expectations will inevitably decline.

In terms of market trends, although global polyethylene production capacity continues to expand, market demand growth is weak. The global economic downturn has affected the cost profit margin, and HDPE costs are expected to decrease in the coming months. Market sentiment is supported by macroeconomic factors, but the increasing supply-demand imbalance has led to an inevitable price decline. The newly added production capacity is mainly concentrated in the North China region, and the regional allocation of production capacity is gradually rationalized, breaking the current situation of mismatch between production and demand regions.

(3) Analysis of the Current Status of the Antioxidant Industry

Antioxidants refer to a type of chemical substance that can delay the oxidation and aging of high polymers. The presence of only a small number of antioxidants can delay or inhibit the oxidation process of polymers, thereby preventing their aging and extending their lifespan. Antioxidants are mainly used in the fields of plastics and rubber.

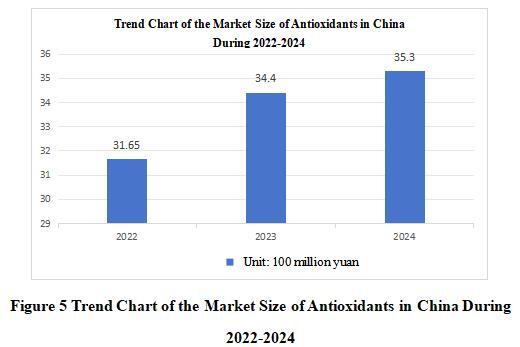

In recent years, with the sustained, stable, and rapid development of China’s economy, applications in fields such as automobiles, building materials, home appliances, and electronics have been continuously strengthened. The plastic products industry has shown a rapid development trend, with the total market demand constantly increasing, which has also driven the demand for antioxidants. In terms of changes in market size, in the past three years, mainly affected by the COVID-19, downstream demand fluctuated greatly, and the market size declined. It is expected that with the economic recovery in the future, the demand for downstream polymer materials will gradually rise, and the market size of the antioxidant industry will maintain a growth trend. The market size of antioxidants in China was 3.44 billion yuan in 2023.

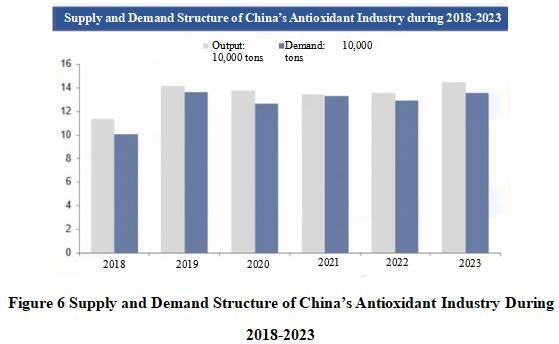

The reasons for the increase in production in China’s antioxidant industry mainly include the following aspects: increasing market demand, especially in the fields of food, medicine, cosmetics, rubber and plastics; The government has introduced a series of policies to support industry development, promoting industry standardization and technological progress; Technological innovation and production process improvement have improved production efficiency and product quality; And the export growth brought about by the expansion of international markets. These factors have collectively driven the sustained growth of China’s antioxidant industry production. In 2023, the output of China’s antioxidant industry was 144,700 tons, with a demand of 135,700 tons.

In the consumption structure of China’s antioxidant industry, hindered phenolic antioxidants account for the heaviest proportion, followed by organic phosphite antioxidants. Hindered phenolic antioxidants have become a major part of the market demand due to their efficient antioxidant properties and wide range of applications, and are widely used in industries such as plastics, rubber, and oil products; Organic phosphite antioxidants, due to their excellent antioxidant and stability properties, also have a significant market demand in fields such as plastics and resins.

There are many manufacturers of antioxidants in China, and most of them mainly produce hindered phenolic antioxidants, with a relatively single product range. The largest production scale is Linyi Sanfeng Chemical, accounting for about 23% of the market share; Lianlong holds a market share of about 17%. Linyi Sanfeng and Yingkou Fengguang mainly produce universal antioxidants and supply them to Sinopec and PetroChina systems, with a relatively stable market share; Lianlong used to focus on specialized antioxidants, but with the expansion of its Zhuhai base, the production capacity of general-purpose antioxidants will also be significantly increased.

By now, the antioxidant industry has entered a relatively stable stage of development. The use of antioxidants has widely penetrated into many fields, including food, medicine, chemical, plastic and other industries. The variety of antioxidant products is rich and diverse, with superior performance, and market competition is gradually becoming fierce. At this stage, technological innovation remains an important driving force for the development of the antioxidant industry. Enterprises will continuously improve their technology and conduct R&D to meet market demand and pursue higher quality products.

1.1.3 Technical analysis

The product of this project is a composite antioxidant, which can be obtained by adjusting the ratio of main and auxiliary antioxidants and granulation process to meet user requirements. The production process includes auxiliary antioxidant phenol phosphite system (auxiliary antioxidant 618), auxiliary antioxidant dilauryl thiodipropionate system (auxiliary antioxidant DLTP), main antioxidant CPL (p-cresol dicyclopentadiene butyl product) system, and mixed slice packaging system for related intermediates.

Phenol Phosphite System (Auxiliary Antioxidant 618): First, distilled phosphorus trioxide and pentaerythritol are used to synthesize pentaerythritol bis(phosphite chloride), which is then subjected to alcohol exchange reaction with octadecanoic acid vinegar to obtain auxiliary antioxidant 618 (O,O'-Dioctadecylpentaerythritol bis (phosphite)) under mutual transfer catalysis. After washing and filtering, it is sent to the intermediate 618 storage tank.

Dilauryl thiodipropionate system (auxiliary antioxidant DLTP): Sodium sulfide dissolved in water and acrylonitrile are condensed to obtain thiodipropionitrile powder with a water content of 20%. After acidification, washing, crystallization, and drying with 31% hydrochloric acid, thiodipropionic acid is obtained. Then, under the action of solid acid catalyst p-toluenesulfonic acid, it reacts with dodecanol to generate auxiliary antioxidant DLTP (dilauryl thiodipropionate).

CPL system: Raw materials such as methylphenol, dicyclopentadiene, and isobutene are condensed and alkylated in toluene solvent to produce crude products, which are then washed with water and subjected to toluene distillation to obtain the main antioxidant CPL.

Mixed slicing packaging system: The antioxidant DSP6168 product is prepared by mixing and slicing the main antioxidant CPL with auxiliary antioxidants 618 and DLTP.

1.1.4 Advantageous conditions of project construction

(1) Policy advantages

The Implementation Plan for Innovative Development of Fine Chemical Industry (2024-2027) clearly states that by 2027, positive progress will be made in the extension of fine chemical industry in the petrochemical industry. Focusing on the needs of economic and social development, we will tackle a number of key products and further enhance the supply chain guarantee capabilities of key industries; Breakthrough a batch of key technologies for greening, safety, and intelligence, significantly improve energy efficiency, significantly reduce total volatile organic compound emissions, and significantly improve intrinsic safety levels; Cultivate more than 5 world-class enterprises with strong innovation leadership and collaborative integration capabilities, cultivate more than 500 specialized, refined, and innovative “little giant” enterprises, create more than 20 chemical industrial parks dominated by fine chemicals and with strong competitive advantages, and form an innovative development system that integrates large, medium, and small enterprises and collaborates with upstream and downstream enterprises.

The Implementation Guide for Digital Transformation of Petrochemical and Chemical Industry proposes that by 2026, the digital networking level of petrochemical and chemical industry will be significantly improved, the integration of data and reality will continue to deepen, the intelligent manufacturing capacity of enterprises will be significantly enhanced, the platform services based on industrial Internet will make positive progress, and the artificial intelligence engine oriented to subdivided industries will be preliminarily formed, and the leading position in process industry will continue to be consolidated from “deepening application” to “reform leading”.

The Investment Promotion Policy of Jilin City clearly states that the investment projects of Jilin Industrial Investment Guidance Fund should comply with national and relevant industrial policies and development plans, with a focus on investing in tourism, medicine and health, aviation, information technology, new materials, advanced equipment manufacturing, biotechnology, energy conservation and environmental protection, new energy, cultural creativity, modern agriculture, modern service industry and other related industries in Jilin City’s “6411” industrial plan, as well as other areas supported by the municipal government for development with focus. In addition to setting up sub-funds through equity participation, the Guidance Fund can also adopt investment methods such as follow-up investment and direct investment; Newly introduced investment projects that meet the conditions shall enjoy tax reductions and exemptions in accordance with the current national and provincial tax policies. For projects with a significant contribution rate in Jilin City, in accordance with the spirit of the document Notice of the State Council on Relevant Matters Concerning Tax Preferential Policies (GF[2015] No. 25), relevant departments shall assist the enterprises in applying for tax exemptions and reductions in accordance with the law and regulations; Establish a special fund for the development of industrial enterprises, and encourage the introduction of major projects in traditional industries such as chemical, automobile, metallurgical, and agricultural product processing in the “6411” industrial system that comply with national industrial policies, have strong industrial support, and have a significant driving effect; Encourage the introduction of emerging industries such as medicine and health, new materials, advanced equipment manufacturing, and electronic information. Lay emphasis on the allocation of production factors, and give priority to recommend relevant national and provincial special funds for support.

(2) Resource advantages

Jilin City has great potential for resource development. The installed capacity of power sources in the city is 10 million KW, with an additional 3.279 million KW added during the 14th Five-year Plan period, an average annual growth rate of 8.3%. Among them, coal-fired power generation is 3.07 million KW, accounting for 30.7%; Gas power generation is 860,000 KW, accounting for 8.6%; Wind power is 1.54 million KW, accounting for 15.4%; PV power generation is 700,000 KW, accounting for 7%; hydropower generation is 3.5 million KW (conventional hydropower generation of 3.2 million KW and pumped storage is 300,000 KW), accounting for 35%; biomass power generation is 270,000 KW, accounting for 2.7%; waste generation is 58,000 KW, accounting for 0.6%; while the installed capacity of new and renewable energy accounts for 60.7% of the total installed capacity. It is expected that by 2025, the power generation will have reached 20.63 billion kWh, and the total transformer capacity of urban and rural power grids will have reached 4891.1 MVA.

The available land area in Jilin City is 853 hectares, including 74 hectares of commercial land, 500 hectares of industrial and mining storage land, 179 hectares of residential land (including guaranteed land for affordable housing), and 100 hectares of other land (including land for public management and public services, transportation, water bodies and water conservancy facilities, and special land). There is a large stock of exploitable land resources, and newly added and reserved land can meet the needs of new projects. Land prices are at a low level among 41 cities in Northeast China.

(3) Industrial advantages

Jilin City is an old industrial base city in Northeast China, known as the cradle of the national chemical industry, the first metallurgical industrial base, and the mother of hydropower in New China. During the “First Five-Year Plan” period, among the 156 key projects in the country, Jilin City achieved “7 and a half” (Jilin Dye Factory, Jilin Fertilizer Factory, Jilin Calcium Carbide Factory, Jilin Carbon Factory, Jilin Ferroalloy Factory, Jilin Thermal Power Plant, New China Sugar Factory construction and operation, and Fengman Power Plant expansion), contributing the first bag of fertilizer, the first barrel of dye, and the first furnace of calcium carbide to the country. In terms of the chemical industry, it has nearly a thousand sets of chemical industrial scale or above facilities, with 11 sets of facilities including methyl isobutyl ketone and methyl methacrylate ranking among the top three in China in terms of production capacity. The construction of Jilin Chemical’s 1.2-million-ton ethylene transformation and upgrading project, with a total investment of 33.9 billion yuan, is progressing in an orderly manner. This is the largest industrial project in Jilin Province since the establishment of the People’s Republic of China, and also the first chemical project of China Petroleum Group to fully use green electricity. After completion and operation, CPC Jilin Chemical Company will enter the world as a world-class enterprise. In terms of carbon fiber industry, it has the only “National-level Carbon Fiber High-tech Industrialization Base” approved by the Ministry of Science and Technology of the People’s Republic of China, forming the most complete carbon fiber industrial chain in China from “acrylonitrile to acrylonitrile-based raw silk to carbon fiber to downstream products”. The raw silk production capacity ranks first in the world, while the carbon fiber production capacity ranks first in China and second in the world. In terms of metallurgical industry, it has the largest metallurgical base in the province, and 2 national metallurgical technology centers. Jianlong Group has become the first steel production enterprise in the province. Antioxidants in Jilin City can be prioritized for supply to Jilin Petrochemical’s linear and ABS equipment.

(4) Talent advantages

Jilin City has universities such as Northeast Electric Power University, Jilin General Aviation Vocational and Technical College, Jilin Technology College of Electronic Information, Jilin Vocational College of Industry and Technology. These universities provide a continuous stream of talent support for enterprises. These talents not only possess rich practical experience, but also have high technical level and innovation ability. They are able to solve various technical problems in the production process, and improve the production efficiency and product quality. Meanwhile, these professional skilled talents can actively participate in the technological innovation and product research and development work of the enterprises, providing strong guarantees for the sustainable development of the enterprises.

Meanwhile, Jilin City has a large number of high-quality industrial workers. After training by enterprises and public welfare institutions, more than 10,000 skilled talents are sent to the society every year, and more than 20,000 people of various types are trained for the society every year. The advantage of labor resources is obvious, and the proportion of skilled workers is at a high level in the Northeast urban agglomeration. The labor force is in a dividend period, and the labor cost is relatively low, which can meet the needs of various enterprises.

(5) Location advantages

Jilin City is located in the central eastern part of Jilin Province, is adjacent to Yanbian Korean Autonomous Prefecture to the east, Changchun City and Siping City to the west, borders Harbin City, Heilongjiang Province to the north, and borders Baishan City, Tonghua City and Liaoyuan City to the south.

Jilin City is located at the geographical center of Northeast Asia, with various forms of transportation including railways, highways, water transportation, and aviation, etc. The artery traffics such as Jilin Longjia International Airport and Jilin Airport, Changchun-Hunchun and Shenyang-Harbin Expressways, Changchun-Hunchun Intercity Express Railway, and Shenyang-Harbin Double-track Railway form a convenient three-dimensional transportation network extending in all directions in Jilin City.

1.2 Contents and scale of project construction

1.2.1 Construction scale

After completion, the project can produce 15,000 tons of antioxidant DSP6168 annually.

1.2.2 Construction contents

The project is being constructed within the existing site area, with a total construction area of 18,000㎡. It mainly includes the construction of R&D plants, testing and inspection centers, production plants, etc., and the purchase of a production line capable of producing 15,000 tons of antioxidant DSP6168 annually.

1.3 Total investment of the project and capital raising

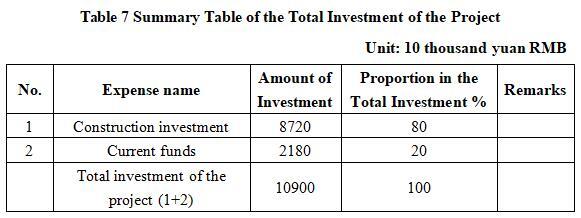

1.3.1Total investment of the project

The total investment of the project is 109 million yuan, including the construction investment of 87.2 million yuan, and current funds of 21.8 million yuan.

1.3.2 Capital raising

Raised by the enterprise itself.

1.4 Financial analysis and social evaluation

1.4.1 Main financial indexes

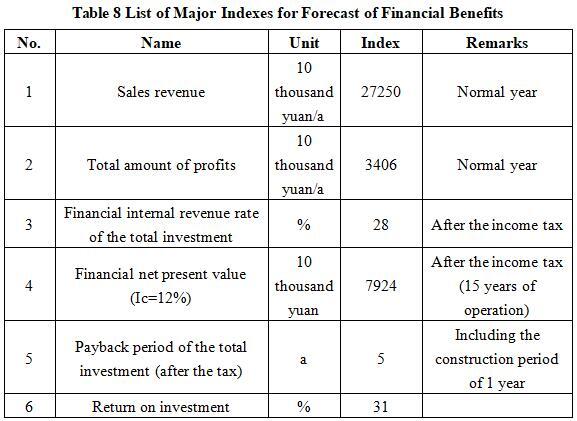

After the project reaches the production capacity, its annual sales revenue will be 272.5 million yuan, its profit will be 34.06 million yuan, its investment payback period will be 5 years (after the tax, including the construction period of 1 year) and its return on investment will be 31%.

Note: “10 thousand yuan” in the table is in RMB

1.4.2 Social evaluation

With the completion and operation of domestic olefin plants and the rapid growth of plastic production capacity, the production and consumption of antioxidants have also increased. The construction of the DSP6168 antioxidant project with an annual output of 15,000 tons in Jilin City will help meet the market’s demand for high-performance antioxidants and promote the sustainable development of the domestic antioxidant industry. Meanwhile, the implementation of this project will also help enhance the independent R&D capabilities and production scale of domestic antioxidant products, and narrow the gap with advanced production levels abroad.

In the production process of antioxidant DSP6168, advanced production technology and processes shall ensure the quality and stability of the product. Therefore, the construction of this project will help promote technological innovation and industrial upgrading, improve the production efficiency and product quality of the entire industry. Meanwhile, by introducing and digesting advanced foreign technologies, it can also promote technological progress and industrial upgrading in the domestic antioxidant industry.

1.5 Cooperative way

Joint venture or cooperation, other ways can be discussed in person.

1.6 What to be invested by the foreign party

Funds, other ways can be discussed in person.

1.7 Construction site of the project

Jilin Economic and Technological Development Zone.

1.8 Progress of the project

It is in planning phase.

2. Introduction to the Partner

2.1Basic information

Name: Jilin Economic and Technological Development Zone Management Committee

Address: Jilin Economic and Technological Development Zone

2.2 Overview

Established in 1998, Jilin Economic and Technological Development Zone is located in Northwest Suburb of Jilin City, with a distance of 85km from the provincial capital Changchun, and in April 2010, it was promoted to a national-level economic and technological development zone upon approval by the State Council, where, its administrative area is 93.06k㎡, and its national planning area is 20.4k㎡, and four boundaries of the planning area are as follows: Block 1: it extends to Songhuajiang River in the east, Jiuzhan Village of Jiuzhan Town in the south, Toutaizi Village of Jiuzhan Town in the west, and Tongxihe River in the north. Block 2: It extends to Jilin City Academy of Agricultural Sciences in the east, Jiulong Road of the Development Zone in the south, Changchun-Tumen Railway in the west, and Jiuxing Road of the Development Zone in the north. Block 3: It extends to Changchun-Tumen Railway in the east, Fanrong Village of Jiuzhan Town in the south, Koujia Village of Jiuzhan Town in the west, and Toutaizi Village of Jiuzhan Town in the north. It has passed ISO14001 Environmental Management System and ISO9001 Quality Management System Certifications, and is the core area of national-level carbon fiber high-tech industrial base in Jilin, as well as the most competitive fine chemical industry agglomeration area in Northeast China.

2.3 Contact method

Contact method of the unit where the project is located:

Contact unit: The Fourth Bureau of Investment Promotion of Jilin Economic and Technological Development Zone

Contact: Xiao Han

Tel: +86-432-66490867

E-mail: 523835785@qq.com

Contact method of the city (prefecture) where the project is located:

Contact unit: Investment Promotion Service Center, Bureau of Commerce of Jilin City

Contact person: Jiang Yuxiu

Tel: +86-432-62049694

+86-15804325460

E-mail: jlstzcjfwzx@163.com