Petrochemical

1,600 Tons/Year Polypropylene Thermoplastic Elastomer Project of Siping City

1. Introduction to the Project

1.1 Project background

1.1.1 Product introduction

Product Name: Chlorinated Polypropylene (CPP). Product specifications: Produced by aqueous phase method, presenting white or slightly yellow granules, with a chlorine content ranging from 20%-38%. Product quality standards: As a R&D product, with increasingly strict environmental regulations, universities in the United States, Japan, and China release relevant research reports and innovative processes every year. The aqueous phase process used by us is at the leading level in China by now. The product is widely used, which is applicable for fields such as ink, coatings, and adhesives.

1.1.2 Market prospect

(1) Market Status of CPP

In recent years, China’s fine chemical industry has shown the following competitive characteristics:

The fine chemical industry system has been preliminarily established: the main raw materials for the production of fine chemical products are basic chemical products. Through years of continuous development, China’s chemical industry has established a relatively complete chemical industry system, with a wide variety of chemical products and a large production capacity and output base for some key raw materials. The complete industrial chain system of China’s chemical industry provides sufficient and low-cost raw material supply, abundant human resources, and low labor costs for the domestic fine chemical industry, giving China’s fine chemical industry a certain comparative advantage internationally. Some key raw material production enterprises have large production capacity and output base, and their output of more than ten major chemical products ranks among the top in the world.

The competitive advantages are becoming increasingly evident: China’s chemical industry has a solid foundation, low labor costs, and significant competitive advantages in the international market. With the further transfer and concentration of the world’s fine chemical industry to China, valuable opportunities have been brought for the development of China’s fine chemical industry.

With the continuous progress of domestic education, scientific research, and industrial economy, a large number of scientific researchers with strong R&D capabilities and skilled workers with rich operational experience have been cultivated in China. In certain fields, the technical processes of fine chemical production enterprises have reached the international advanced level.

As an important organic chemical raw material, CPP is widely used in various fields such as coatings, plastics, rubber, inks, adhesives, etc. With the continuous advancement of technology, CPP are used more widely, indicating that its future market prospects are very broad.

The distribution of chlorinated polyethylene (CPE) consumption regions in the world is mainly concentrated in China in Asia, the United States and South America in the Americas, and Europe. Globally, CPE has successfully replaced products such as chlorosulfonated polyethylene rubber (CSM), chloroprene rubber (CR), nitrile rubber (NBR) in the rubber field, and its production and application in wire and cable, rubber hose and tape have shown a growing trend year by year. With the continuous improvement of the cost-effectiveness of CPE, the demand for its use in plastic profiles continues to grow in various countries, leading to a sustained increase in the demand for CPE.

CPE is mainly used in PVC plastic products, wires and cables, transport belts, automotive and industrial rubber hoses, sealing strips, waterproofing membranes, foam products, rubber products, magnetic rubber strips, thermoplastic elastomers and other fields worldwide.

By now, the production technology of chlorinated polyethylene in China has matured. After decades of development, China’s CPE industry has reached a world leading level. By now, China has become the world’s largest producer of CPE. Domestic CPE production enterprises are mainly concentrated in Shandong region, accounting for about 52% of the total domestic production capacity.

(2) Market prospect of CPP

By now, the domestic CPP market is mainly supplied by domestic production enterprises. However, with the continuous strengthening of environmental policies and the increasing entry barriers to the industry, small production enterprises will be eliminated, and the industry concentration will continue to increase. Meanwhile, with the technological progress and upgrading of downstream industries, the market demand for CPP will continue to increase. It is expected that the CPP market will maintain a rapid growth trend in the coming years.

According to market research institutions, CPP has shown a steady growth trend during 2020- 2024. This growth is mainly due to the increased market demand in multiple fields such as sports, healthcare, ink, and textiles. Especially in the field of ink, with the rapid development of digital printing and packaging industries, the demand for CPP as an important raw material will continue to increase. Meanwhile, in the textile industry, CPP has also received widespread attention and application due to its excellent waterproof, flame-retardant and other properties, and the market demand is steadily increasing.

In the field of coatings, CPP can be used to produce high-end automotive paint, furniture paint, industrial paint and other coatings, with decorative and protective properties. With the rapid development of industries such as automobiles and furniture, the demand for coatings in the market will continue to grow, thereby driving the demand for CPP in the market.

In the field of plastics, CPP can be used to produce plastic products such as wires and cables, pipelines, and sheets, with excellent heat resistance, corrosion resistance, and insulation properties. With the continuous advancement of urbanization and the rapid development of new energy vehicles, the demand for plastic products market will continue to grow, thereby driving the demand for CPP market.

In the field of rubber, CPP can be used to produce rubber products such as rubber soles, tires, and rubber gloves, with excellent wear resistance, slip resistance, and aging resistance. With the rapid development of industries such as sports and healthcare, the demand for rubber products will continue to grow, thereby driving the demand for CPP market.

In the field of ink, CPP can be used to produce printing ink, UV ink, etc., with excellent friction resistance, corrosion resistance, and vivid color. With the rapid development of digital printing and packaging industries, the demand for ink market will continue to grow, thereby driving the demand for CPP market.

Furthermore, CPP is widely used in the textile industry, such as producing high-performance waterproof coatings and flame retardant materials. With the increasing demand from consumers for the safety performance of clothing and household products, the demand for CPP in the textile industry is also steadily rising.

In terms of environmental protection, the expansion of the application scope of CPP, as an environmentally friendly material, helps to reduce the use of traditional harmful solvents, which is in line with global environmental trends. Therefore, with the increasing global environmental awareness, the market prospects of CPP will be even broader.

Looking ahead, the market demand for CPP is expected to continue to grow until 2030. With the recovery of the global economy and the development of various industries, the application fields of CPP will be further expanded, and the market prospects are very broad. Meanwhile, with the increasing awareness of environmental protection, chlorinated polypropylene, as an environmentally friendly material, will receive more attention and support for its application, providing strong guarantees for the long-term development of the market.

1.1.3 Technical analysis

The technology and process proposed for the project are at a leading level in China.

1.1.4 Advantageous conditions of project construction

(1) Policy advantages

The Ministry of Industry and Information Technology and nine other departments have issued a notice on the Implementation Plan for Innovative Development of the Fine Chemical Industry (2024-2027). The document requires increased policy support. Strengthen the coordination between fiscal, financial, regional, investment, import and export, energy, ecological environment, price and other policies and industrial policies. Implement the special work of “integration of technology industry and finance”, relying on the evaluation of hard technology attributes and the mechanism of listing cultivation, as well as local policy support, to guide social capital to support early technological innovation in the fine chemical industry. Encourage the transformation and upgrading of the national manufacturing industry, industrial investment funds such as the National Small and Medium sized Enterprise Development Fund, and social capital such as financial institutions to support the development of fine chemical enterprises.

Siping City is committed to creating a cluster effect in the chemical industry, optimizing the industrial structure, and promoting industrial upgrading. A series of specific measures have been introduced. Firstly, a chemical industry park will be established to provide policy support such as tax incentives and land use convenience for settled enterprises. Secondly, we will increase research investment in the chemical industry and encourage cooperation between enterprises, universities, and research institutions to jointly develop new technologies and products. Finally, Siping City will strengthen environmental supervision to ensure the sustainable development of the chemical industry and protect the ecological environment.

With the implementation of these policies, the chemical industry in Siping City is expected to achieve a qualitative leap in the near future, becoming an important pole of the chemical industry in Northeast China and even the whole country.

(2) Industrial advantages

Siping New Development Zone takes the development of new industrialization as its core, undertakes the transfer of industrial advantages and radiation driving effects, follows the principles of green development and circular economy, and takes equipment manufacturing, fine chemicals, biochemistry, green building materials, and commercial logistics as its leading industries. The district is committed to building a comprehensive new industrial economic development zone that integrates industrial production, R&D innovation, commercial and office work, residential communities, logistics and warehousing, and supporting services.

Given the current industrial landscape and future development trends, the chemical industry has been identified as a strategic core to accelerate the construction of chemical industrial parks. By now, two chemical industrial parks have been established in the district, which have developed three main branches: basic chemical, fine chemical, and daily chemical. The leading products include ion exchange membrane caustic soda, liquid chlorine, cefuroxime acid, etc. In recent years, chemical industrial parks have shown rapid development momentum through continuous cultivation and expansion.

The raw materials for the polypropylene thermoplastic elastomer required for the project are all from the surrounding market, with stable supply and convenient transportation. Meanwhile, the project benefits from reliable partners and stable supply channels, and the procurement process is simple and easy to implement.

(3) Location advantages

The Xinkai District is located on the First-level Harbin-Dalian Development Axis for revitalization of Northeast China. It is 80 km away from Changchun, 120 km away from Longjia Airport, 190 km away from Shenyang, 230 km away from Jitaoxian Airport, 380 km away from Yingkou Port, and 580 km away from Dalian Port. Several major transportation arteries in the Northeast region, including the Beijing-Harbin Railway, Harbin-Dalian High-speed Railway, National Highway 102, Jiji-Shuangliao Expressway, Harbin- Dalian Expressway, and Ji’an-Xilingol League Abaga Banner Expressway, all pass through the area. There are 2 railway stations, 8 railway dedicated lines, and 3 highway exits in the surrounding area. Siping Station is one of the 18 freight marshalling yards in China’s railways, an important transportation hub in Northeast China, with convenient transportation of raw materials and products.

(4) Talent advantages

Xinkai District collaborated with Changchun Institute of Applied Chemistry, Chinese Academy of Sciences to establish a science and technology innovation center platform, collaborated with Xi’an Jiaotong University National Technology Transfer Center to establish Xi’an Jiaotong University Siping Center, and collaborates with Dalian Institute of Chemical Physics to establish Siping Research Branch; It has unique advantages in promoting the R&D of new chemical materials and the transformation of achievements. Research institutes and universities such as Changchun Institute of Chemical Engineering Chinese Academy of Sciences, Xi’an Jiaotong University, Dalian Institute of Chemical Physics, Jilin University, Harbin Institute of Technology, Dalian Institute of Technology, Northeast Normal University, Jilin University of Chemical Technology, etc. provide talent and technological support for enterprises; Meanwhile, it can also provide technology services, technology transfer, achievement transformation, fund introduction, and consulting services for enterprises in the park. Several universities, including Siping Vocational University, Jilin Engineering Vocational College, and Lishu Vocational High School, provide employment security.

1.2 Contents and scale of project construction

The overall planning area is 10,000 ㎡, with the construction of production area, office and living area, warehouse area, purchase of production, automation control system, auxiliary production projects, and purchase of 107 sets of production equipment. Annual production of 1,600 tons of polypropylene thermoplastic elastomer.

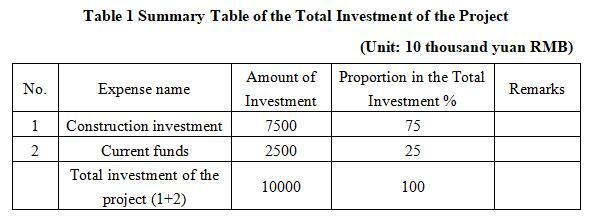

1.3 Total investment of the project and capital raising

The total investment of the project is 100 million yuan, including the construction investment of 75 million yuan.

1.4 Financial analysis and social evaluation

1.4.1 Main financial indexes

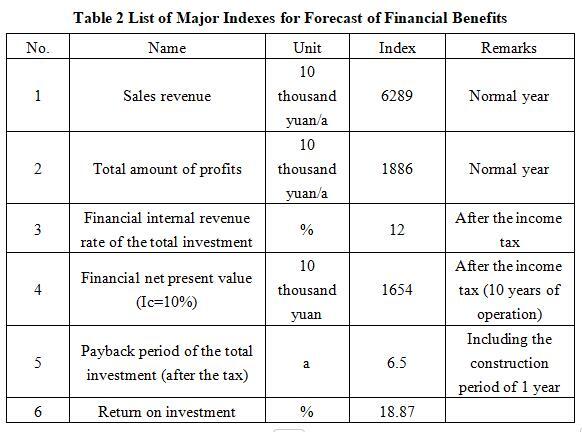

After the project reaches the production capacity, its annual sales revenue will be 62.89 million yuan, its profit will be 18.86 million yuan, its investment payback period will be 6.5 years (after the tax, including the construction period of 1 year) and its return on investment will be 18.87%.

Note: “10 thousand yuan” in the table is in RMB

1.4.2 Social evaluation

Environmental benefits: Polypropylene material (PP) is a low-carbon, environmentally friendly, and recyclable polymer material, with minimal negative impact on the environment during its production and use. There are various processing methods, including injection molding, extrusion, and blow molding, etc. These processing methods are not only efficient but also reduce environmental pollution.

Economic benefits: Through technological innovation and industrial upgrading, the PP project can improve production efficiency, reduce production costs, and thereby increase the economic benefits of the enterprise. Furthermore, PP materials are widely used in various fields, such as rubber products, asphalt modifiers, polymer modifiers, adhesives, etc., which further promotes the development of related industries.

Employment opportunities: The construction and operation of PP project will create a large number of employment opportunities, including production, processing, sales, and other aspects, which will help alleviate social employment pressure.

Technological innovation and industrial upgrading: The PP project has promoted the progress of related technologies and the sustainable development of the entire industry through technological innovation and industrial upgrading. This innovation not only improves product quality, but also expands new application areas and enhances market competitiveness.

1.5 Cooperative way

Sole proprietorship, joint venture and cooperation.

1.6 What to be invested by the foreign party

Funds, other ways can be discussed in person.

1.7 Construction site of the project

Siping New Industrial Economic Development Zone Ecological Chemical Industrial Park

1.8 Progress of the project

The project proposal has been prepared

2. Introduction to the Partner

2.1 Basic information of unit

Name: Management Committee of Siping New Industrial Economic Development Zone

Address: Guojiadian Town, Lishu County, Siping City, Jilin Province

2.2 Overview of unit

Siping New Industrial Economic Development Zone is an important economic development zone in Siping City, Jilin Province. It was established on December 7, 2016 and is a provincial-level economic development zone officially approved by the Jilin Provincial Government. The zoning plan, land use plan, industrial plan, safety assessment, and environmental impact assessment of the newly opened zone have been approved, and the safety risk assessment of the chemical industrial park has been passed. In 2022, the provincial chemical industrial park was recognized and rated as Level C.

Geographical location and transportation conditions

The Siping New Industrial Economic Development Zone is located at the economic center of Northeast China, with convenient transportation. The development zone is 80 km away from Changchun City, 120 km away from Longjia Airport, 190 km away from Shenyang City, 230 km away from Taoxian Airport, 380 km away from Yingkou Port, and 580 km away from Dalian Port. There are 2 railway stations nearby, 8 dedicated railway lines, and 3 highway entrances.

Industrial layout and development situation

The Siping New Industrial Economic Development Zone mainly cultivates three leading industries: medicine, health, green food, automobile and equipment manufacturing, and modern services. By now, there are 12 high-tech enterprises, 10 provincial-level specialized and innovative enterprises, 12 provincial-level technology R&D centers, and 6 provincial-level science and technology small giant enterprises in the development zone. It has 3 well-known Chinese trademarks, 5 provincial-level famous trademarks, 7 provincial-level famous brand products, and has obtained more than 100 invention patents.

Situation of Ecological Chemical Industrial Park

The planned area of the ecological chemical park in Siping New Industrial Economic Development Zone is 12.15 k㎡, with a focus on developing two major industrial chain clusters: fine chemical and chlor alkali chemical. Several chemical enterprises have settled in the park, such as Siping Fine Chemicals Co., Ltd. and Shuangliao Haohua Chemical Co., Ltd. The policy of “leaving the city and entering the park” has implemented in the park to promote the entry of chemical enterprises into the park, forming an industrial agglomeration effect, and achieving a safety risk Level D.

Development of New Energy Chemical Industry

The Siping New Industrial Economic Development Zone is also actively developing the new energy and chemical industry, relying on abundant biomass resources such as straw and cow manure, and introducing multiple key projects. The new materials industry park within the park has established a platform for high-level innovation and entrepreneurship talents to pilot, transform, and scale up scientific and technological achievements, attracting scientific and high-end talent resources and promoting industrial innovation and development.

2.3 Contact method

Contact unit: Investment and Operation Bureau of Siping New Development Zone

Contact person: Yu Quan

Tel: +86-13844482777

E-mail: xkqtzyxj@126.com

Contact method of the city (prefecture) where the project is located:

Contact unit: Siping Municipal Economic and Technical Cooperation Bureau

Contact person: Wen Dacheng

Tel: +86-434-3260536

E-mail: spjhjjhk@163.com