Petrochemical

Natural Gas to Synthetic Oil Project of Songyuan City

1. Introduction to the Project

1.1 Project background

1.1.1 Product introduction

The main advantage of Gas to Liquids (GTL) is that it does not contain harmful components such as sulfur, nitrogen, nickel impurities, and aromatic hydrocarbons. Therefore, it is a clean fuel that fully meets the strict requirements of modern engines and constantly evolving environmental regulations. For example, the EU has reduced the sulfur content in diesel to 30 μg/g, while the United States has reduced the sulfur content in diesel to 15 μg /g. Through the Fischer Tropsch process, natural gas is converted into diesel fuel with a sulfur content of less than 1 μg /g, aromatic content of less than 1% (by volume), and a cetane number exceeding 70, which opens up a new path for the production of clean fuels.

Furthermore, using GTL indirect conversion technology, synthetic lubricants and specialty chemicals can also be produced. Paraffin wax is an ideal raw material for the production of detergent intermediates (such as linear alkylbenzene, alcohols, etc.), plasticizers, auxiliary chemicals, and additives. Mixed paraffin can be used as a low polarity, odorless solvent for coatings and other applications. Synthetic lubricants, with their high viscosity index and low volatility, have become high-performance base oils in the fields of industrial and automotive lubricants.

1.1.2 Market prospect

(1) Current situation of natural gas to synthetic oil market

Synthetic oil, a lubricating oil obtained through chemical synthesis or refining processing, gradually occupies an important position in many fields due to its excellent performance and environmental characteristics. With the steady growth of the global economy and the continuous increase in energy demand, the synthetic oil industry has ushered in new development opportunities. As one of the world’s largest energy consuming countries, China has enormous potential for the development of its synthetic oil market.

In recent years, the production capacity of China’s synthetic oil industry has continued to grow. By 2023, the current production capacity of the domestic base oil industry has reached 16.47 million tons per year, while the long-term shutdown capacity is 3.94 million tons. According to the production capacity data, with an average growth rate of 6.98% over the past five years, indicating a stable growth trend in the industry. Especially in 2019, production capacity grew rapidly, with the commissioning of new facilities in major refineries resulting in a base oil production capacity growth rate of 11.43%. By 2023, the growth rate of base oil production capacity was 3.13%, and newly put into operation facilities mainly focused on the three types of base oil and high-end white oil fields.

The import volume of China’s synthetic oil market has been declining year by year, mainly due to the continuous improvement of domestic refining capacity and the improvement of domestic base oil quality. The average import volume over the past five years was 2.3411 million tons, with an average growth rate of -8.45%. At present, domestic base oil imports are mainly concentrated in Class II and Class III base oils, and the main import sources include South Korea, Singapore and Taiwan, China.

The global natural gas to oil market is gradually expanding in size. On the one hand, more and more countries are beginning to attach importance to the research and promotion of natural gas to oil technology due to considerations of environmental protection and energy security. On the other hand, natural gas rich regions such as the United States and the Middle East are actively developing the natural gas to oil industry driven by market demand.

Synthetic oil, as a high-quality lubricant and fuel substitute, continues to grow in demand worldwide. Especially in high-end manufacturing, transportation, and new energy sectors, synthetic oil is favored for its excellent performance. As one of the world’s largest energy consuming countries, China has enormous potential for the development of its synthetic oil market. In recent years, the production capacity of China’s synthetic oil industry has continued to expand, and the market size has been growing year by year.

Synthetic oil is a lubricating oil obtained through chemical synthesis or refining processing methods. It uses higher quality components in crude oil to achieve the desired molecular morphology through chemical reactions and human control. The molecules of synthetic oil are arranged neatly and have strong resistance to external variables, resulting in excellent quality. Its ability to resist thermal stability, antioxidant reactions, and viscosity changes is significantly better than that of mineral oil.

Synthetic oil is derived from gas in crude oil or ethylene and propylene dispersed from natural gas, and is refined into base oil macromolecules through complex chemical reactions such as polymerization and catalysis (Fischer Tropsch synthesis technology, also known as GTL technology). Due to its unique production process and molecular structure, synthetic oil has significant advantages in performance and service life. As an alternative petroleum fuel made from non-biological raw materials, synthetic oil is mainly used in aviation, automotive, and industrial fields. Compared with traditional petroleum, synthetic oil has lower carbon emissions and higher energy density, making it a more environmentally friendly and sustainable energy choice.

(2) Market prospects for natural gas to synthetic oil production

With the recovery of the global economy and the sustained growth of the Chinese economy, the demand for synthetic oil market is showing an upward trend. Especially in high-end manufacturing, transportation, and new energy industries, synthetic oil has become an indispensable part of key materials due to its excellent lubrication performance and extremely low wear rate. In the industrial field, synthetic oil is widely used in precision machinery and aerospace equipment; In the field of transportation, it is mainly used for engine lubrication and fuel systems in automobiles, ships, and airplanes.

With the increasing awareness of environmental protection and the strengthening of government environmental policies, the synthetic oil industry is expected to develop towards a more environmentally friendly and sustainable direction. Synthetic oil, as a high-quality lubricant and fuel substitute, has lower carbon emissions and higher energy density, meeting the requirements of environmental protection and sustainable development.

Future Development Trends:

1. Continuous growth: With the development and utilization efficiency of natural gas resources, it is expected that China’s natural gas to oil industry will maintain stable growth in the coming years. With the implementation of the 14th Five-Year Plan, the strategic position of natural gas as a clean energy source will be further strengthened.

2. Technological innovation: Technological innovation will be the key to driving industry development. The R&D of new catalysts, more efficient conversion processes, and technological breakthroughs in waste resource utilization will help improve the economy and environmental friendliness of natural gas to oil production.

3. Green transformation: With the proposal of carbon neutrality goals, the natural gas to oil industry will pay more attention to green production, and achieve sustainable development through reducing carbon emissions, improving energy efficiency, and other means.

4. International Cooperation: China’s natural gas to oil industry will also strengthen international cooperation, introduce advanced technology, optimize the layout of the industrial chain, and enhance overall competitiveness. The development and import of overseas natural gas resources will also bring new development opportunities to the domestic industry.

The natural gas to oil industry in China has achieved significant results in market share, but there is still enormous potential for development. Faced with environmental pressures and changes in market demand, the industry needs to constantly innovate and improve technology to achieve green and efficient development. In the future, natural gas to oil production will become an important driving force for China’s energy structure transformation, contributing to national energy security and sustainable economic and social development.

1.1.3 Technical analysis

The Gas to Liquid (GTL) indirect conversion technology is used, which consists of three main parts: synthesis gas production, Fischer Tropsch synthesis, and product refining. Firstly, through the production of synthetic gas, followed by the use of Fischer Tropsch synthesis technology, synthetic gas can be converted into synthetic oil. Modern Fischer Tropsch synthesis technology, relying on slurry bed reactors with new cobalt-based catalysts, has become a recognized route for synthesis processes.

(1) Synthesis gas production

Synthesis gas is produced using partial oxidation technology. During this process, natural gas burns at extremely high temperatures (1,200 ℃- 1,500 ℃) and pressures (over 14 MPa) without the need for catalysts. In large-scale production, using oxygen instead of air can produce a hydrogen to carbon monoxide (H2/CO) ratio that is close to ideal.

(2) Fischer Tropsch synthesis

Fischer Tropsch synthesis can convert synthesis gas into a range of alkanes and alkenes with different chain lengths, while also producing other liquid products such as methanol, ammonia, or dimethyl ether. Fischer Tropsch synthesis typically uses iron-based or cobalt based catalysts and is carried out at moderate temperatures (200 °C-300 °C) and pressures (1-4 MPa). Fischer Tropsch synthetic oil is similar to clean light crude oil.

(3) Product refinement

The hydrocarbon products produced by Fischer Tropsch synthesis have different chain lengths. Long-chain hydrocarbons can be cut off and converted into short chain normal and isomeric alkanes with excellent low-temperature performance using mild hydrocracking/hydroisomerization processes, thereby obtaining high-quality jet fuel and diesel blending materials. The produced naphtha has low sulfur and high wax hydrocarbon content. Although it is not the best choice as a gasoline component, its high wax hydrocarbon content makes it an excellent petrochemical raw material. The synthetic paraffin produced from this is priced higher than petroleum paraffin and is suitable for the production of specialty products. According to the new environmental regulations, GTL technology has a cost advantage of nearly 40% Compared with traditional processes. The emission pollution of using GTL diesel is significantly lower than that of conventional diesel, especially the reduction of particulate matter emissions by 46%. Due to the low sulfur content, the sulfate particles in the exhaust are reduced; High cetane number and low aromatic content improve combustion efficiency, thereby reducing emissions of nitrogen oxides and particulate matter.

1.1.4 Advantageous conditions of project construction

(1) Policy advantages

Development orientation of fine chemical industry is clearly pointed out in the 14th Five-Year Development Plan for Petrochemical Industry of Jilin Province. Extending the fine chemical industry chain from solving the transition from zero to high-quality development. Traditional fine chemical industry should be further upgraded, to meet requirements of downstream manufacturing industry for high-performance, safety and green development, improve the product quality and grade, and develop toward specialty and refinement.

(2) Industrial advantages

Qianguo County is adjacent to Daqing Oilfield, and Jilin Oilfield is located within its borders. Daqing Oilfield and Jilin Oilfield are the first and sixth largest oil fields in China, respectively, with a total oil and gas production of 47 million tons. Sinopec Northeast Oil and Gas Branch, Sinopec Northeast Oil and Gas Branch, Sinochem Group Changshan Chemical Co., Ltd., and PetroChina Pipeline Changchun Oil and Gas Branch have settled in China, with a strong industrial foundation.

The Ulantuga Industrial Park has obvious resource advantages, with proven oil reserves of 30 million tons and natural gas reserves of 100 billionm³ in the area. The former large oil production plant natural gas joint gas station located in Ulantuga Town is the hub for the outward dispatch of natural gas in the nearby area. The imported natural gas pipeline (China-Russia East Line) passes through Ulantuga and has two gate stations in the industrial park, which can supply 1 millionm³of natural gas per day. Meanwhile, Sinopec Northeast Oil and Gas Branch can also supply 300,000m³of natural gas per day, providing sufficient oil and gas resources for the Park to meet the production needs of the project. The surrounding infrastructure of the project construction site is complete, with convenient transportation and relatively complete construction conditions.

(3) Location advantages

Qianguo County is located in the central area of the three northeastern provinces and Inner Mongolia. From the perspective of China’s map, it is situated at the eye of the rooster and is a transportation hub and important node city in Northeast China. The county urban area is located in the same city as Songyuan urban area, connecting 8 cities and 14 counties, with a population of over 34 million. The domestic road network is well connected, with multiple national and provincial highways such as Daqing-Guangzhou Expressway, Hunchun-Ulanhot Expressway, and Mingshui-Shenyang Highway intersecting vertically and horizontally; The Changchun-Baicheng Railway runs through the entire area from north to south, and after the high-speed train accelerates, it only takes 50 minutes to drive from Changchun. The Songhua River and Nenjiang River waterways are unobstructed, and the Qian Gorlos waterway can directly connect to the Russian Port of Khabarovsk. Songyuan Chaganhu Airport is located within the county, connecting 9 large and medium-sized cities including Beijing, Shanghai, and Dalian, and has initially formed a 3D, fast, and diversified transportation system.

Ulantuga Industrial Park is located in the western part of Qian Gorlos Mongolian Autonomous County, Jilin Province, at the junction of four counties (Nong’an, Changling, Qian’an, and Qian Gorlos), with a superior geographical location. From the Park to Songyuan: a total distance of 83 km; The entire journey from the Park to Qian Gorlos is 80 km. The Park is located within the economic radiation range of major cities such as Shenyang, Changchun, Songyuan, and Daqing, with a well-developed transportation network. The Mingshui-Shenyang Highway (New and Old 203 Highway) and Changchun-Baicheng Railway Highway intersect here, providing convenient conditions for logistics transportation in the Park.

(4) Talent advantages

Songyuan City has established 11 industrial colleges, scientific research internship and training bases, and doctoral workstations to support rural revitalization with 7 provincial universities including Jilin University and Jilin University of Finance and Economics. These collaborations have attracted a large number of high-level talents and college graduates to come to Songyuan for scientific research, study, work, and life. They have established a “Talent Home · Project Special Class” and connected 126 industrial projects and 83 talent projects. Through the integration platform of industry and talent, they have attracted a large number of high-level talents to provide sufficient talent support for the projects.

Qianguo County has achieved the rational allocation of human resources, improved the overall quality of labor force, and promoted the rational flow and utilization of talents through the “direct bridge” of precise employment, the “convenient bridge” of employment training, and the “overpass” of efficient and smooth employment services.

1.2 Contents and scale of project construction

The total planned land area is 50,000 ㎡; The construction area is 35,000 ㎡, with the purchase of production equipment and the installation of three production lines. The project has an annual production capacity of 80,000 tons of diesel; Naphtha: 50,000 tons; High- quality paraffin: 20,000 tons.

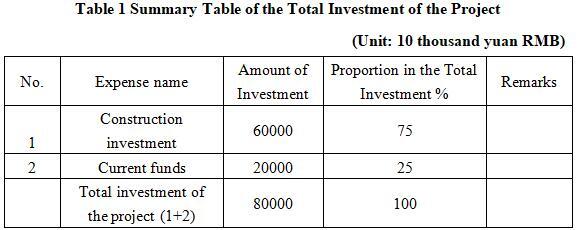

1.3 Total investment of the project and capital raising

The total investment of the project is 800 million yuan, including the construction investment of 600 million yuan.

1.4 Financial analysis and social evaluation

1.4.1 Main financial indexes

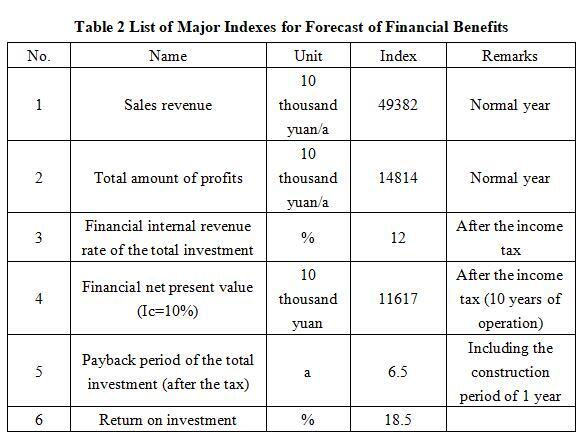

After the project reaches the production capacity, its annual sales revenue will be 493.82 million yuan, its profit will be 148.14 million yuan, its investment payback period will be 6.5 years (after the tax, including the construction period of 1 year) and its return on investment will be 18.5%.

Note: “10 thousand yuan” in the table is in RMB

1.4.2 Social evaluation

Promoting local economic growth: The implementation of natural gas to synthetic oil projects is expected to significantly promote rapid local economic growth. The signing and construction of the project will promote the improvement of local infrastructure and increase employment opportunities, thereby stimulating the prosperity of the local economy.

Promoting industrial chain upgrading: The natural gas to synthetic oil project will promote the development of related industrial chains including natural gas extraction, synthetic oil production, logistics transportation, etc., build a complete industrial chain system, and enhance the overall competitiveness of local industries.

Expanding the job market: The construction and operation of the project are expected to create numerous job opportunities, covering both direct and indirect employment levels. After the completion of the project, it will provide a large number of job opportunities for local residents, which will have a positive effect on improving their employment rate and income level.

Accelerating technological innovation and industrial progress: With the continuous innovation of natural gas to synthetic oil technology, production costs are gradually decreasing, making the product more competitive in the market.

Improving energy efficiency: The natural gas to synthetic oil project helps reduce dependence on crude oil and coal, improve the efficiency of natural gas use, and play a positive role in energy conservation, emission reduction, and environmental quality improvement.

1.5 Cooperative way

Sole proprietorship, joint venture and cooperation.

1.6 What to be invested by the foreign party

Funds, other ways can be discussed in person.

1.7 Construction site of the project

The proposed location is Ulantuga Industrial Park in Qianguo County.

1.8 Progress of the project

The project proposal has been prepared

2. Introduction to the Partner

2.1 Basic information of unit

Name: Qianguo County Investment Promotion Service Center

Address: 909 Ulan Street, Qianguo County

2.2 Overview of unit

Ulantuga Industrial Park is located in the western part of Qian Gorlos Mongolian Autonomous County, Jilin Province, at the junction of four counties (Nong’an, Changling, Qian’an, and Qian Gorlos). The Park was established in 2004 and was approved as a municipal industrial park by the Municipal Party Committee and Government in 2005. In 2008, it was recognized as a provincial Characteristic Park.

Geographical location and transportation: Ulantuga Industrial Park has a superior geographical location, located within the economic radiation range of major cities such as Shenyang, Changchun, Songyuan, and Daqing. The Park has convenient transportation, with the intersection of Mingshui-Shenyang Highway (New and Old 203 Line) and Changchun-Baicheng Railway Highway Central Line. It is 83 km away from Songyuan, 120 km away from Changchun, 300 km away from Shenyang, and 245 km away from Harbin.

Infrastructure: The controlled area of the Park is 20 k㎡, and the development area is 5.5 k㎡. The infrastructure construction of the Park is complete, including main roads, power facilities, natural gas pipelines, drainage, water supply, flood control, communication transmission and other projects, meeting the standard of “seven connections and one leveling”, and possessing the basic conditions to carry large projects and develop large industries.

Resource endowment: The Ulantuga Industrial Park is rich in natural gas resources. The Songyuan Gas Extraction Plant of PetroChina Jilin Oilfield is located in the Park, with proven natural gas reserves of 100 billion and a daily output of 2 millionm³, delivering 1 million m³ of natural gas to the outside world. The natural gas pipeline of Sinopec Chaganhua gas field is directly laid to the Park, providing sufficient power guarantee for the development of the oil and gas chemical industry.

Industrial foundation: The Park has initially formed a group development model with Tianfu Industrial as the main green energy processing industry, Dongxiang Company producing ultrafine glass fibers and glass balls as the main glass fiber manufacturing industry, and Hongqiao Enterprise Group’s wood product processing industry.

2.3 Contact method

Contact unit: Qianguo County Investment Promotion Service Center

Contact: Li Xiaochun

Tel:+86-13351556769+86-0438-5098098

E-mail: zsjxmk2209905@163.com

Contact person of the city (prefecture) where the project is located:

Contact unit: Songyuan Municipal Commerce Bureau Investment Attraction Service Center

Contact person: Yu Lili

Tel: +86-18004388787