Petrochemical

50,000 Tons/Year Hydrocyanic Acid Project of Songyuan City

1. Introduction to the Project

1.1 Project background

1.1.1 Product introduction

Hydrocyanic acid (HCN) is an essential key raw material in chemical production. According to data, nearly 80% of pharmaceutical intermediates and nearly 60% of pesticide intermediates can be prepared through the synthesis route of HCN. Therefore, HCN plays a crucial role in the fine chemical industry chain, supporting a large and dynamic circular economy industry chain.

This project is highly consistent with national and local industrial development policies, and the external conditions required for construction are already in place. The technology used is leading, and the project not only has significant economic benefits, but also significant social benefits. The feasibility of implementation is very strong.

The main raw material carbon dioxide required for the project comes from the exhaust emissions of Sinopec Northeast Oil and Gas Branch, Sinochem Group Changshan Chemical Co., Ltd., China Datang Group Changshan Thermal Power Plant and other units. These raw materials have stable supply and low cost, creating a high profit margin for the project.

1.1.2 Market prospect

(1) Current market situation of hydrocyanic acid

HCN, an extremely weak acid, specifically referring to an aqueous solution of hydrogen cyanide, belongs to Class A inorganic highly toxic substances. Inhaling high concentrations of hydrogen cyanide gas in a short period of time may lead to respiratory arrest or even death. Despite its extremely high toxicity, the application of HCN is quite extensive, mainly involving industries such as nylon, acrylonitrile, acrylic resin, pesticides, electroplating, and mining. Its main production methods include formamide dehydration method, methane ammonification oxidation method, methane ammonification dehydrogenation method, propylene ammonification oxidation method, and light oil cracking method. In China, the propylene ammoniation oxidation method is the main method for producing HCN. In recent years, with the continuous development of derivatives of HCN, the production of HCN has continued to increase. HCN has become an important raw material in C1 chemistry and competes with carbon monoxide chemistry. At present, the demand for HCN derivatives is increasing both domestically and internationally. The emergence and increase in production of these derivatives are changing the supply and demand pattern of HCN, and the demand continues to rise.

HCN belongs to fine chemical products and is widely used in multiple industries and fields. Its main uses include:

Organic Chemistry: HCN is an important raw material for synthesizing organic compounds, commonly used in the manufacture of organic products such as organic glass, lactic acid, and melamine.

Electroplating: In the electroplating industry, HCN is used for processes such as copper plating, gold plating, and silver plating.

Mining: In the mining industry, HCN is used to extract precious metals such as gold and silver.

Pesticides: HCN and its derivatives have important applications in pesticide manufacturing, such as the synthesis of pesticide intermediates.

Medicine: HCN and its derivatives are also widely used in the field of medicine as important raw materials for drug synthesis.

Dyes and Metallurgy: HCN and its derivatives also have important applications in the dye and metallurgical industries.

In 2022, six ministries and commissions of the country issued the Guidelines on Promoting High-quality Development of the Petrochemical Industry during the 14th Five-year Plan Period, emphasizing the importance of developing new chemical materials and fine chemicals, accelerating the digital transformation of the industry, and improving the level of intrinsic safety and clean production. This will accelerate the quality, efficiency, and power transformation of the petrochemical industry, and promote China’s transition from a major petrochemical and chemical country to a strong nation. During the 14th Five-Year Plan period, the pace of industry structural adjustment and transformation and upgrading will further accelerate, and the industrial development model is shifting from capacity construction for scale expansion to refined, specialized, and serialized segmented market expansion. Currently, safety and environmental protection have become the industry’s bottom line and basic requirements for development. Meanwhile, chemical industrial parks characterized by green, circular, and low-carbon have gradually become the main carriers for industry structural adjustment, transformation, upgrading, and development. During the 14th Five-Year Plan period, with the strong recovery of the world economy, the demand for oil, gas, and petrochemical products is expected to maintain stable growth. In the global growth of petrochemical demand, the consumption of chemical products has grown the fastest, especially in the United States and China.

(2) Market prospect of hydrocyanic acid

In recent years, the demand for HCN in the market has steadily increased, mainly due to the advancement of industrialization and the development of emerging industries. As a key chemical raw material, HCN has been widely used in various fields such as organic synthesis, pharmaceuticals, and pesticide production, and its market demand continues to rise.

The continuous growth of industrial demand: With the deepening of industrialization, the application of HCN in organic synthesis, pharmaceuticals, and pesticide production is becoming increasingly widespread. The continuous expansion of these industries has further stimulated the demand for HCN.

The promotion of emerging industries: The rise of emerging industries has also promoted the development of the HCN market. Taking HCN as a key raw material for adiponitrile as an example, with the increasing demand in the nylon 66 market, the market demand for HCN has also grown.

The HCN preparation technology used in this project meets the requirements of national green technology innovation and helps to promote the achievement of the national “dual carbon” goal; Meanwhile, the project also promotes the green and low-carbon preparation process of HCN, accelerating the development of the fine chemical industry and making green development a conscious pursuit of the whole society.

In the current market environment, the production and application of HCN are facing unprecedented opportunities and challenges. On the one hand, with the strengthening of environmental regulations and the increasing public awareness of environmental protection, traditional high pollution chemical production methods are gradually being phased out, providing broad development prospects for the green preparation technology of HCN. On the other hand, the downstream application areas of HCN are constantly expanding, especially in strategic emerging industries such as new materials and new energy, where the demand for HCN as a key raw material continues to grow.

In order to meet market demand and respond to national policies, this project not only attaches importance to the green preparation technology of HCN, but also strives to develop efficient utilization pathways for HCN. Production costs can be reduced and economic benefits can be enhanced by optimizing production processes, reducing the generation of by-products, improving the conversion rate and selectivity of HCN. Furthermore, the Project Team is actively researching the potential applications of HCN in other fields, such as electronic chemicals, high-performance fibers, etc., to further expand the market for HCN.

According to market research data, the market demand for HCN has shown a steady growth trend during 2020- 2024. Especially in 2020, despite the impact of the global pandemic on the chemical industry, the production and application of HCN still maintained a high growth rate. This is mainly due to the widespread application of HCN in strategic emerging industries such as new materials and new energy, as well as the strengthening of national environmental policies, which have promoted the development of green preparation technology for HCN.

After entering 2021, with the gradual recovery of the global economy, the HCN market has experienced explosive growth. Not only does it continue to maintain stable demand in traditional fields such as pesticides and pharmaceuticals, but it also shows a rapid growth trend in emerging fields such as new energy and electronic chemicals. This growth trend continued until 2024, during which the market size of HCN continues to expand, and both production and sales have achieved significant increases.

Looking ahead, it is expected that the HCN market will continue to maintain strong growth momentum until 2030. With the global emphasis on environmental protection and sustainable development, the green preparation technology of HCN will be widely applied and promoted, and its downstream application fields will also continue to expand and deepen. This will bring new development opportunities and challenges to the HCN industry, while also providing investors with broad market space and development prospects.

With China’s “dual carbon” goal of peaking carbon emissions before 2030 and achieving carbon neutrality before 2060, green, environmentally friendly, and low-carbon lifestyles are gradually becoming mainstream. In summary, under the background of green and low-carbon economy, the market demand for HCN, as an important chemical raw material, is expected to continue to grow. This project is expected to become a key force in promoting the sustainable development of the HCN industry through technological innovation and market expansion, and contribute to achieving the national “dual carbon” goal.

1.1.3 Technical analysis

The project adopts the production process of Ansett method to produce HCN. Both Sichuan Natural Gas Chemical Research Institute and Tsinghua Ziguang Yingli Company have mature technologies in China. This method uses methane, ammonia, and air as raw materials, and platinum as a catalyst to produce HCN. At present, the Andrussow process is one of the main methods for industrial production of HCN abroad, with industrial scale production facilities in countries such as the United States, Italy, Japan, Australia, South Africa, the United Kingdom, and the Netherlands. Andrussow process is a mature technique, economically reasonable, and uses natural gas (methane) as raw material, with abundant resources.

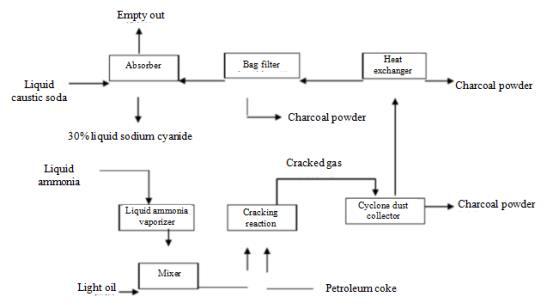

Process Flow Chart for Preparing HCN by Andrussow Process

1.1.4 Advantageous conditions of project construction

(1) Policy advantages

The Implementation Plan for Innovative Development of the Fine Chemical Industry (2024-2027): jointly issued by the Ministry of Industry and Information Technology, the National Development and Reform Commission, and nine other departments, aims to promote the innovative development of the fine chemical industry. By 2027, China’s petrochemical and chemical industry will make positive progress in fine extension, break through a number of key technologies, improve energy efficiency, reduce total emissions, and cultivate world-class enterprises and specialized, refined, and new “little giant” enterprises.

The Work Plan for Stable Growth in the Petrochemical and Chemical Industry: jointly issued by seven ministries including the Ministry of Industry and Information Technology, the National Development and Reform Commission, and the Ministry of Finance, with an implementation period of 2023-2024. The main goals include expanding effective investment, enriching high-quality supply, stabilizing foreign investment and trade, strengthening factor supply, and stimulating enterprise vitality.

In terms of policy support, Songyuan City and Qianguo County have actively responded to the national call and introduced a series of specific measures to promote the development of the fine chemical industry. The Songyuan Municipal Government has particularly emphasized its support for high-tech enterprises, providing strong guarantees for the innovation and upgrading of the fine chemical industry through various policies such as tax reductions, funding subsidies, and talent introduction. Meanwhile, Songyuan City also focuses on improving the industrial chain, encouraging local enterprises to cooperate with advanced domestic and foreign enterprises to jointly develop new products and technologies, in order to enhance the competitiveness of the entire industry.

Qianguo County, relying on its abundant natural resources and geographical advantages, focuses on developing upstream and downstream industries related to fine chemicals. The county government has established industrial parks to attract investment and provide a comprehensive service platform integrating R&D, production, and sales for fine chemical enterprises. Furthermore, Qianguo County attaches great importance to environmental protection and sustainable development, requiring all chemical projects to comply with strict environmental standards to ensure that industrial development is coordinated with ecological environment protection.

The implementation of these policies has not only brought new development opportunities for the fine chemical industry in Songyuan City and Qianguo County, but also injected new vitality into the transformation and upgrading of the entire regional economy. With the gradual manifestation of policy effects, it is expected that in the next few years, Songyuan City and Qianguo County will become important bases for China’s fine chemical industry, making positive contributions to the high-quality development of the national petrochemical industry.

(2) Industrial advantages

Qian Gorlos has 7 development zones and industrial parks, including 1 provincial development zone (Jilin Qian Gorlos Economic Development Zone, Chaganhu Tourism Economic Development Zone, Cross Strait (Jilin) Ecological Agriculture Cooperation Pilot Zone “Three Zones in One”), 4 municipal level industrial parks (Changshan Industrial Park, Ulantuga Industrial Park, Wangfu Industrial Park, Chaganhua Animal Husbandry (Chemical) Park), and 2 county-level parks (Hongqi Industrial Park, Chaganhu Airport Economic Park), with a planned total area of 1,291 k㎡ and complete infrastructure. Especially with the establishment of “green power” demonstration parks within the country, the comprehensive electricity price can be reduced to a minimum of 0.36 yuan/kWh, providing the most favorable electricity price for high energy consuming enterprises in the province.

The raw material for the production of HCN is natural gas. Natural gas is a clean energy source and also a high-quality chemical raw material. Qianguo County has abundant mineral resources, with proven oil reserves of 320 million tons and natural gas reserves of 100 billionm³. This provides unique conditions for implementing the national “14th Five-Year Plan” and developing the fine chemical industry.

(3) Location advantages

Changshan Industrial Park is located in the central area of urban development along the Hunchun–UlanHot transportation axis, and is an important node connecting Songyuan City and Baicheng City. It is 42 kilometers from Songyuan City and 176 kilometers from Changchun City to the south. It is 25 kilometers from Da’an City and the waterway port, 144 kilometers from Daqing City, and 178 kilometers from Harbin City to the north. It is 18 kilometers from Chagan Lake Scenic Area to the west and 65 kilometers from Zhaoyuan to the east. There are Hunchun-Ulanhot Expressway, Changchun-Baicheng Railway, and National Highway 302 passing through the Park, providing convenient transportation.

The park has convenient surrounding transportation, sound infrastructure, flat terrain, no pollution around, sufficient water and electricity supply, and developed communication, and it is suitable for investment and construction.

(4) Talent advantages

Songyuan City has established 11 industrial colleges, scientific research internship and training bases, and doctoral workstations to support rural revitalization with 7 provincial universities including Jilin University and Jilin University of Finance and Economics. These collaborations have attracted a large number of high-level talents and college graduates to come to Songyuan for scientific research, study, work, and life. They have established a “Talent Home · Project Special Class” and connected 126 industrial projects and 83 talent projects. Through the integration platform of industry and talent, they have attracted a large number of high-level talents to provide sufficient talent support for the projects.

Qianguo County has achieved the rational allocation and efficient utilization of human resources through the “direct bridge” for precise employment, the “convenient bridge” for employment training, and the “overpass” for employment services. The government has gained a deep understanding of employment demand, launched the “Sending Jobs, Policies, Warmth” campaign, developed internship positions, improved labor quality, and perfected the public employment service system.

(5) Advantages of safety and environmental protection measures

This project will strictly comply with relevant national and local laws and regulations, design and construct comprehensive safety facilities and environmental emission systems. In terms of safety facilities, advanced fire alarm systems, automatic fire extinguishing systems, leak detection and control systems, etc. will be equipped to ensure the safety and controllability of the production process. Meanwhile, regular inspections and maintenance of safety facilities will be carried out to ensure their normal operation. In terms of environmental emissions, advanced production processes and pollution control technologies will be used to effectively treat the waste gas, wastewater, waste residue, etc. generated during the production process, ensuring that emissions meet relevant national and local standards. Furthermore, a comprehensive environmental monitoring and management system will be established to monitor emissions in real time, ensuring the stable operation of environmental protection facilities and meeting emission standards.

1.2 Contents and scale of project construction

Covering an area of 50,000 ㎡. This project has added a new construction area of 45,500 ㎡, including 17,000 ㎡ of productive buildings, 18,500 ㎡ of auxiliary production facilities, 1,250 ㎡ of public works buildings, and 8,750 ㎡ of office and living facilities. After completion, the annual production of HCN will be 50,000 tons.

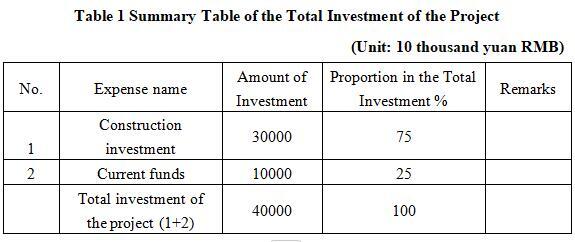

1.3 Total investment of the project and capital raising

The total investment of the project is 400 million yuan, including the construction investment of 300 million yuan.

1.4 Financial analysis and social evaluation

1.4.1 Main financial indexes

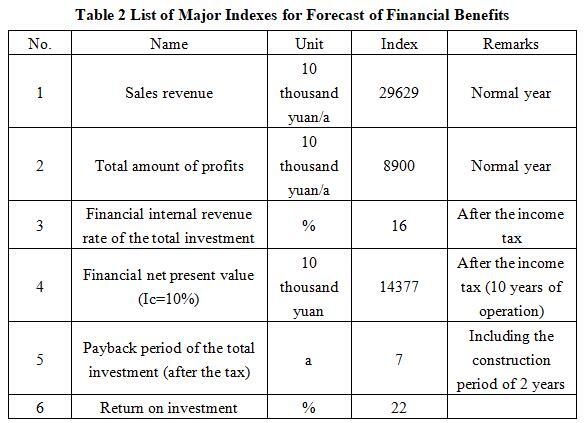

After the project reaches the production capacity, its annual sales revenue will be 296.29 million yuan, its profit will be 89 million yuan, its investment payback period will be 7 years (after the tax, including the construction period of 2 years) and its return on investment will be 22%.

Note: “10 thousand yuan” in the table is in RMB

1.4.2 Social evaluation

The social benefits of producing HCN are significant. As an important chemical raw material, it is widely used in industries such as industry and agriculture, promoting the development of related industrial chains, such as the synthesis of intermediates in the pharmaceutical, pesticide, dye and other industries. Meanwhile, the production of HCN has also promoted technological innovation and process improvement, improved production efficiency, and saved costs.

After the completion of the project, it can create 1,000 job opportunities for society. Furthermore, this project actively promotes the adjustment and optimization of the structure, technical structure, organizational structure, and product structure of the HCN industry, further expanding the supply categories and scale of HCN products, and promoting the diversified development of the HCN industry.

1.5 Cooperative way

Sole proprietorship, joint venture and cooperation.

1.6 What to be invested by the foreign party

Funds, other ways can be discussed in person.

1.7 Construction site of the project

The project is planned to be built in Changshan Industrial Park

1.8 Progress of the project

The project proposal has been prepared

2. Introduction to the Partner

2.1 Basic information of unit

Name: Changshan Chemical Industry Park, Qianguo County

Address: Changshan Town, Qian Gorlos Mongolian Autonomous County, Songyuan City

2.2 Overview of unit

Changshan Industrial Park is a city level industrial park approved by the Municipal Party Committee and Government in August 2003, located in Changshan Town, Songyuan City, Jilin Province. For many years, the Park has adhered to the work philosophy of “industrial support, project driving, park carrying, and private entities”, highlighting the development of circular economy projects and investment attraction as the two key points, strengthening infrastructure construction, improving the software and hardware environment for investment attraction, and continuously improving the overall level.

Geographical location and transportation conditions

Changshan Industrial Park is located in the central area of urban development along the Hunchun–UlanHot transportation axis, and is an important node connecting Songyuan City and Baicheng City. It is 42 kilometers from Songyuan City and 176 kilometers from Changchun City to the south. It is 25 kilometers from Da’an City and the waterway port, 144 kilometers from Daqing City, and 178 kilometers from Harbin City to the north. It is 18 kilometers from Chagan Lake Scenic Area to the west and 65 kilometers from Zhaoyuan to the east. There are Hunchun-Ulanhot Expressway, Changchun-Baicheng Railway, and National Highway 302 passing through the Park, providing convenient transportation.

Infrastructure and resource advantages

There is one 66 kV substation in the Park with a capacity of 63,000 kVA to ensure the electricity supply for enterprises. The Park has negotiated with Xinli Oil Production Plant to add a backup power source. Furthermore, the Park plans to build one sewage treatment plant with a daily treatment capacity of 10,000 tons of sewage. The infrastructure of the Park is becoming increasingly perfect, basically achieving “seven connections and one leveling”, providing a good investment environment for project construction.

Industry positioning and development direction

The Park focuses on developing three leading industries: the building materials processing industry based on the resources of electricity and chemical plants, mainly developing enterprises such as fly ash fired bricks, cement products, building insulation materials, waterproof materials, plastic steel doors and windows, colored plastic steel sheets, and fly ash cement blocks. Furthermore, the Park also has abundant resources of electricity, heat, chemical gases, and fly ash, as well as abundant underground oil and natural gas reserves.

2.3 Contact method

Contact unit: Songyuan Municipal Commerce Bureau Investment Attraction Service Center

Contact person: Wang Xiyue

Tel: +86-18343830830