Petrochemical

Comprehensive Utilization Project of Leather Waste of Songyuan City

1. Introduction to the Project

1.1 Project background

1.1.1 Product introduction

The comprehensive utilization of leather waste is based on the generation of hazardous waste, introducing waste treatment technology from hazardous waste treatment stations to treat waste such as chromium containing waste flakes, and realizing the resource utilization of waste. Due to the needs of economic development, the amount of waste generated by leather enterprises in Songyuan City has been increasing year by year, and it is urgent for the local authorities in Songyuan to make every effort to address the disposal of hazardous waste. For Ningjiang District, if we can do a good job in the resource utilization of hazardous waste such as leather on the basis of developing traditional advantageous leather production projects, convert leather scraps into energy that can be stored and transported, and utilize them, it has significant theoretical and practical significance for the local economic development and environmental protection.

1.1.2 Market prospect

(1) Market Status of Comprehensive Utilization of Leather Waste

With the rapid development of China’s national economy and the continuous improvement of people’s living standards, the demand for leather products is also increasing. Due to limited resources and tightening environmental policies, traditional natural leather production capacity continues to decline, and people’s demand for leather products is being replaced by new generation synthetic leather with similar hand feel and performance.

The resource utilization of leather waste conforms to the green trend of the times, indicating that solid waste utilization technology is about to open up a new and vast market, becoming a “new blue ocean” of industry attention. Thus, many leather enterprises have actively responded and entered this field, firmly practicing the concepts of circular economy and energy conservation and emission reduction, and committed to the path of sustainable development. Through technological innovation and model exploration, they not only effectively enhance the recycling value of leather waste, but also inject strong impetus into the transformation and upgrading of the leather industry, jointly promoting the industry to move towards a more environmentally friendly, efficient, and sustainable direction.

Recycled leather, also known as recycled leather, is a high value-added product made by recycling and processing leather waste and scraps generated during leather processing. These waste materials undergo a series of complex processes such as crushing, mixing, compression, bonding, molding, etc., ultimately becoming leather materials with specific properties and appearances.

In recent years, with the introduction of advanced technologies such as intelligent manufacturing and digital production, the recycled leather industry has made significant progress in product quality, production efficiency, cost control, etc. Some enterprises continue to innovate in leather processing, product design, intelligent manufacturing, and other areas, improving the added value and market competitiveness of their products.

Against the backdrop of increasing global environmental awareness, the recycled leather industry is facing increasingly strict environmental regulations and production standards. In order to achieve sustainable development, enterprises have increased their investment in environmental protection, used environmentally friendly production processes and technologies, and reduced pollution emissions during the production process. This not only helps to enhance the company’s sense of social responsibility, but also wins more favor from consumers.

(2) Market prospects for comprehensive utilization of leather waste in Songyuan City

The production of hazardous waste in Jilin Province has been increasing year by year. In response to the national attention to the environment, Jilin Province has successively introduced multiple policies to prevent and control hazardous waste in recent years, supplemented by various policy supports such as electricity tariff discounts. Thanks to favorable policy support and market environment, the centralized hazardous waste treatment project has been successfully carried out.

Due to the needs of economic development, the amount of waste generated by leather enterprises in Songyuan City has been increasing year by year, and it is urgent for the local authorities in Songyuan to make every effort to address the disposal of hazardous waste

① Low utilization rate of raw materials. At present, the utilization rate of raw hides in our country is only about 35%. In the current advanced technology, the utilization rate of pigskin can reach 75% - 85%, the utilization rate of cowhide is 70% - 80%, and the utilization rate of sheepskin and goat skin is 55% - 65%. Even with current advanced technology, a large amount of collagen is not fully utilized and wasted.

② The problem of environmental pollution is extremely severe. The leather industry is a heavy polluting enterprise second only to the paper industry in the light industry. Due to the variety of leather making processes and the use of different chemical agents in different raw materials and process routes, the usual leather making process generates a large amount of solid waste such as wastewater and sludge.

A study has shown that processing 1 ton of raw hides produces about 150 kg of sludge, which includes sludge generated during the leather making process, such as washed sludge mainly composed of chlorides, sulfides, phenols, bacteria, and microorganisms; Rotten wool impregnated sludge mainly composed of sulfides, lime, protein, and pulp; There are also various physical and chemical precipitates generated by terminal sewage treatment. Leather sludge has a high moisture content (up to 90%-98%), and even after pressure filtration or dehydration, its moisture content still reaches 50%-80%. This makes its properties extremely unstable, prone to decay, emits unpleasant odors, and may provide breeding grounds for some dangerous pathogens, parasite eggs, etc., making it a serious source of pollution.

If we can improve the utilization rate of leather waste and recycle it as a resource, it will greatly promote the economic development of Songyuan. The project site is located in Yadahong Industrial Concentration Zone, which conforms to urban planning, avoids urban and environmentally sensitive areas, is 20 km away from the city center, has good transportation conditions, and the surrounding environment is suitable for handling solid waste without affecting rural production and life. The site has an open terrain, which is conducive to intercepting and discharging regional water, and is far away from villages and high-voltage lines, with convenient transportation. The amount of construction for the access road is relatively small, and there are no residential areas nearby. Project construction is very necessary, and after completion, it has good market prospects.

1.1.3 Technical analysis

Phase I- Alkalization

In traditional alkalization methods, in order to improve the quality of animal glue, strict control of alkali concentration, reaction temperature, and gel extraction reaction time is required. While increasing the gel extraction rate, the requirements for reaction conditions and equipment are also high. This experiment adopts a combined method of acidification, alkalization, gel extraction, and chromium mud treatment for gel extraction. This stage is the alkalization stage after the acidification stage treatment. Due to the continued pretreatment of chromium containing dandruff in the first stage, the following objectives were achieved during the alkalization stage:

(1) As the second stage of pretreatment, alkalization is used to separate most of the chromium from the collagen system in the form of precipitated chromium hydroxide.

(2) Due to the hydroxide ions brought by magnesium oxide, the hydroxyl groups in collagen can be blocked, reducing the binding ability between collagen and chromium, ultimately leading to hydrolysis. Therefore, a portion of the collagen can be converted into animal glue, which appears in animal glue due to its good water solubility.

During the constant temperature water bath process, a solid-liquid mixture will appear. Separate the solid-liquid phase and wash the resulting solid material 2-3 times with dilute alkali solution. Where, the solid phase component is chromium hydroxide precipitate. The components in the liquid phase are water and animal glue generated after alkalization and hydrolysis.

Phase II- Acidizing chromium containing dandruff

Compared with traditional simple acidification processes, this acidification treatment stage has the following advantages:

(1) The acidification time is short. Due to the lack of subsequent chromium removal processes in traditional acidification processes, strict requirements are placed on the leaching concentration, reaction temperature, and gel extraction reaction time during the acidification process. The acidification time is relatively long and difficult to control.

(2) The requirement for leaching concentration is relatively low, and traditional processes require strict control of leaching concentration. As the reaction progresses, the acid concentration needs to be adjusted at any time. In this experiment, acidic substances can be added at once to partially acidify in a short period of time, and the resulting product can be further processed in the second stage.

(3) The acidification efficiency is high. In this experiment, oxalic acid was used as the acidifier, which is more likely to hydrolyze leather collagen Compared with other acids such as hydrochloric acid and sulfuric acid.

Phase III - glue extraction stage

Gel extraction, commonly known as boiling gel, is the process of separating animal glue from water in the obtained animal glue solution.

This project adopts the method of vacuum distillation to boil animal gelatin solution. Under reduced pressure condition, the boiling point of animal gelatin solution decreases. Compared with traditional animal gelatin boiling method, it has the following advantages:

(1) Short cooking time

At lower temperatures, the animal gelatin solution can reach boiling. In the boiling state, the water in the animal gelatin solution quickly separates from the solution system, accelerating the drying rate of the animal gelatin. Traditional animal glue method can cause excessive hydrolysis at high temperatures, and prolonged boiling time at low temperatures.

(2) Animal glue is not easily hydrolyzed

At lower temperatures, the hydrolysis rate of animal glue in the solution slows down, allowing for the production of larger molecular weight animal glue products and improving the quality of animal glue.

(3) Save energy

Due to the lower temperature, energy consumption can be reduced, which is in line with China’s energy-saving and emission reduction policies. In industrial production, in addition to using pressure distillation, it is recommended to utilize the waste heat from the distillation process through multi effect evaporation and other means, which can reduce costs and energy consumption.

Phase IV: Treatment of Chromium Mud

Process the solid substances during the extraction of animal glue. The chromium concentration in the obtained waste residue is less than 15 mg/L (standard QB-T31852-2015).

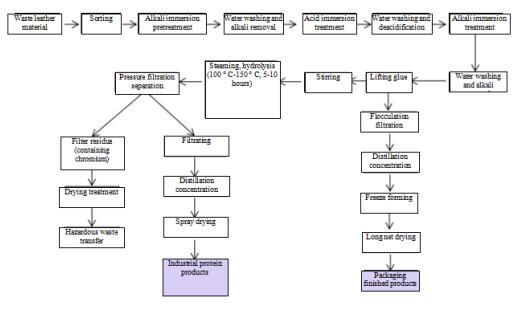

Process flow chart is as follows:

1.1.4 Advantageous conditions of project construction

(1) Policy advantages

The State Council has issued the Action Plan for Peaking Carbon Emissions Before 2030: The circular economy in the Plan proposed to strengthen the comprehensive utilization of bulk solid waste, and the annual utilization of bulk solid waste will reach about 4 billion tons by 2025; By 2030, the annual utilization will reach around 4.5 billion tons.

The 14th Five-Year Plan for the Development of Circular Economy proposes that by 2025, circular production methods will be fully implemented, green design and clean production will be widely promoted, the comprehensive utilization capacity of resources will be significantly improved, and the basic establishment of a resource circular industry system will be achieved. The recycling network for waste materials has become more complete, the ability to recycle renewable resources has been further enhanced, and a resource recycling system covering the entire society has been basically established. The efficiency of resource utilization has significantly improved, and the proportion of renewable resources replacing primary resources has further increased. The supporting and guaranteeing role of circular economy in resource security has become more prominent.

(2) Location advantages

Jilin Ningjiang Economic Development Zone Park is located in the northeast of Songyuan City, on the beautiful and rich banks of Songhua River, adjacent to Daqing-Guangzhou Expressway and 203 National Highway. It is 3 km away from the city center, 50 km away from Chaganhu Airport, 150 km away from Changchun, 130 km away from Harbin, and 5 km away from the east exit of Daqing-Guangzhou Expressway. It is also 20 km away from Songyuan Port and has direct flights to Harbin.

(3) Resource advantages

The project requires corn stalks, straw, etc. to be solved locally and in the surrounding areas. The construction site of this project is Songyuan City and its surrounding areas, which are the main grain producing areas in Jilin Province. Only Songyuan City has a grain output of 7 million tons, and there are at least 3 million tons of crop straw left Furthermore to self-use. The surrounding areas are all major grain producing areas, and the plant straw resources are very abundant, which can fully meet the production needs of this project. The project plans to adopt order agriculture and implement a “company + base + farmers” model to ensure the supply of straw raw materials.

(4) Park advantages

Yadahong Industrial Concentration Zone was established in June 2003 and became one of the first provincial industrial concentration zones in September 2005. In 2022, it was upgraded to a provincial economic development zone and renamed Jilin Ningjiang Economic Development Zone. The total planned area is 28.27 k㎡, including 11 k㎡ of built-up area, all of which have achieved “seven connections and one leveling”. There are seven functional zones including chemical industry zone, comprehensive processing zone, emerging industry zone, new building materials zone, modern logistics zone, headquarters R&D zone, and public service zone. In 2022, the wind power equipment projects of CRRC Group and the energy storage equipment projects of Chint Group, with a total investment of billions, have started construction and are now in production.

1.2 Contents and scale of project construction

The total land area of the project is about 50 mu, with a total construction area of 28,800 ㎡. A new steam turbine room, deaeration and coal bunker room, boiler room, and corresponding supporting auxiliary engineering, public engineering, and environmental protection engineering will be built.

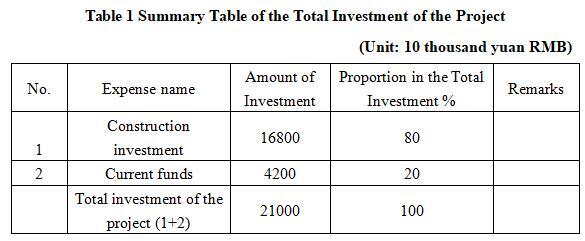

1.3 Total investment of the project and capital raising

The total investment of the project is 210 million yuan, including the construction investment of 168 million yuan.

1.4 Financial analysis and social evaluation

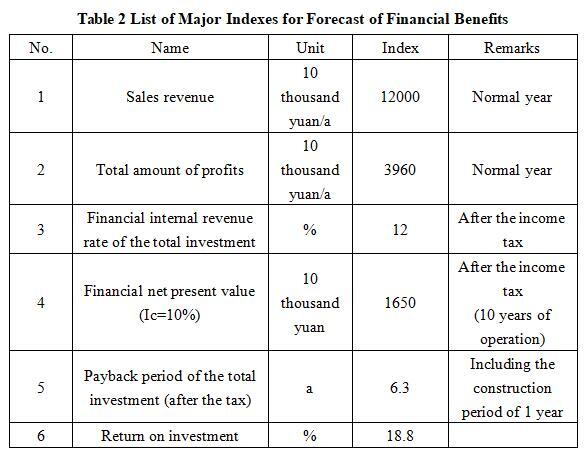

1.4.1 Main financial indexes

After the project reaches the production capacity, its annual sales revenue will be 120 million yuan, its profit will be 39.6 million yuan, its investment payback period will be 6.3 years (after the tax, including the construction period of 1 year) and its return on investment will be 18.8%.

Note: “10 thousand yuan” in the table is in RMB

1.4.2 Social evaluation

The core of environmental issues lies in the rational utilization of resources and the proper disposal of waste produced by humans. As a comprehensive treatment and disposal center for hazardous waste, the consistent purpose of hazardous waste treatment and disposal should be to protect resources, improve the environment, serve the public, and benefit the people. This project has significant social benefits and can maintain certain economic benefits.

1.5 Cooperative way

Sole proprietorship, joint venture and cooperation.

1.6 What to be invested by the foreign party

Funds, other ways can be discussed in person.

1.7 Construction site of the project

Yadahong Industrial Park, Ningjiang District, Songyuan City

1.8 Progress of the project

The project proposal has been prepared

2. Introduction to the Partner

2.1 Basic information of unit

Name: Project Service Center, Ningjiang District, Songyuan City

Address: 519 Heping Road, Ningjiang District, Songyuan City

2.2 Overview of unit

Jilin Ningjiang Economic Development Zone is located in the northeast of Songyuan City, on the beautiful and rich banks of Songhua River, adjacent to Daqing-Guangzhou Expressway and 203 National Highway. It is 3 km away from the city center, 50 km away from Chaganhu Airport, 150 km away from Changchun, 130 km away from Harbin, and 5 km away from the east exit of Daqing-Guangzhou Expressway. It is also 20 km away from Songyuan Port and has direct flights to Harbin. Yadahong Industrial Concentration Zone was established in June 2003, became one of the first provincial industrial concentration zones in September 2005, and was promoted to a provincial economic development zone in 2022. The total planned area is 28.27 k㎡, including 11 k㎡ of built-up area, all of which have achieved “seven connections and one leveling”. There are seven functional zones including chemical industry zone, comprehensive processing zone, emerging industry zone, new building materials zone, modern logistics zone, headquarters R&D zone, and public service zone.

Since its establishment, the concentrated area has adhered to the policy of “high starting point planning, high standard construction, high-quality service, and efficient management”, and followed the principle of “unified planning, step-by-step implementation, and rolling development”. Based on the development concept of building fully functional, industrial clusters, and prominent characteristics, the area is led by emerging industries, highlighting the development of pillar industries such as mechanical processing, petrochemicals, new building materials, and emerging energy. It is firmly committed to the path of new industrialization, creating a first-class industrial concentration zone, and enhancing the core competitiveness of the regional economy. It has successively won the honorary titles of “National Top 100 Scientific Development Demonstration Parks”, “China’s Most Distinctive Industrial Development Zone”, and “China’s Northern Most Investment Potential Industrial Concentration Zone” from relevant national ministries and commissions; The oilfield supporting characteristic industrial park, “provincial characteristic industrial park” and “exemplary organization to boost the development of private economy” rated as key development by the provincial party committee and government; Jilin University has designated it as the “Social Practice Base for College Students”. At present, there are 178 industrial enterprises settled in the development zone, including 47 enterprises above designated size and 11,000 employees.

2.3 Contact method

Contact unit of the project: Project Service Center, Ningjiang District, Songyuan City

Contact person: Gao Lixiang

Tel: +86-0438-3086611

Contact person of the city (prefecture) where the project is located:

Contact unit: Songyuan Municipal Commerce Bureau Investment Attraction Service Center

Contact person: Yu Lili

Tel: +86-18004388787