Petrochemical

Natural Gas Aromatization Fine Chemical Project of Songyuan City

1. Introduction to the Project

1.1 Project background

1.1.1 Product introduction

Aromatization is a newly emerging petrochemical process technology in recent years, which involves heating raw materials to convert them into a gas phase. The gasified raw materials are then heated to a certain temperature in a heating furnace and enter a reactor for aromatization reaction under the action of special catalysts. Most of them are converted into aromatic components such as benzene, toluene, and xylene, while generating dry gas containing hydrogen, methane, ethylene, ethane, propane, and other components. Aromatization ultimately produces aromatic hydrocarbons, including aromatic hydrocarbons, benzene, toluene, and xylene BTX, MTPE, Methanol is widely used in the synthesis of fibers, synthetic resins, synthetic rubber, and various fine chemicals, and is the most basic chemical raw material. Natural gas chemical industry is the process of preparing derivatives from natural gas through direct or indirect conversion. This project uses low-carbon and low sulfur hydrocarbons such as natural gas to produce aromatic products such as triphenyl, improving the scarce market situation.

1.1.2 Market prospect

(1) Current situation of natural gas chemical market

Natural gas chemical industry is an important branch of the chemical industry, which uses natural gas as raw material to produce chemical products. Natural gas is mainly composed of methane, which has the characteristics of high calorific value, low pollution, and easy transportation, and is an important component of modern energy systems. In recent years, the market size of the natural gas chemical industry has continued to expand with the increasing global demand for clean energy and the improvement of environmental awareness.

Especially in China, the development of the natural gas chemical industry has ushered in unprecedented historical opportunities with the government’s high attention to environmental protection and strong promotion of traditional energy substitution policies. Natural gas, as a clean and efficient energy source, not only occupies an important position in the fields of civilian and industrial fuels, but also plays an indispensable role in chemical production. It is mainly composed of methane and has significant characteristics of high calorific value, low pollution, and easy transportation, becoming a key component of modern energy systems. The application fields of natural gas chemical products are extremely wide, covering a series of important chemical raw materials such as fertilizers, methanol, ethylene, propylene, etc. These products are not only the cornerstone of the national economy, but also an important force in promoting industrial modernization.

In recent years, natural gas chemical technology has also been developing rapidly with the continuous advancement and innovation of technology. The new catalytic process, efficient conversion technology, and intelligent production management system make the natural gas chemical production process more efficient and environmentally friendly. The application of these technologies not only improves product quality, but also significantly reduces production costs and enhances the market competitiveness of enterprises.

In terms of market demand, with the acceleration of urbanization and the improvement of residents’ living standards, the demand for clean energy and chemical products continues to grow. The application of natural gas chemical products in various fields, such as construction, transportation, and home appliances, is becoming increasingly widespread, and the market demand is strong. Especially in the context of increasingly strict environmental policies, natural gas, as a clean energy source, has a broader market prospect.

At present, the Chinese natural gas chemical market is in a period of rapid growth, with the industry scale continuously expanding and the industrial chain becoming increasingly perfect. Many enterprises have increased their investment and laid out natural gas chemical projects, striving to occupy a favorable position in market competition. According to relevant data, the natural gas chemical market will continue to maintain a high-speed growth trend in the next few years, with an expected annual growth rate of over 10%. This trend not only provides broad development space for natural gas chemical enterprises, but also injects strong impetus into the sustainable development of the entire industry.

In summary, the natural gas chemical industry is facing unprecedented development opportunities driven by multiple favorable factors such as policy support, technological progress, and market demand. In the future, with the further development and growth of the industry, natural gas chemical industry will play a more important role in promoting economic development, improving energy structure, and promoting environmental protection.

(2)Market prospects of aromatic fine chemicals

In recent years, due to the rapid development of downstream products of aromatic hydrocarbons, the demand for aromatic hydrocarbons in domestic and foreign markets has continued to grow. China is a net importer of “triphenyl”, with an annual shortage of 2 million tons of benzene, 1 million tons of toluene, 2.3-3 million tons of xylene, and 3-5 million tons of methanol.

The advantages of using natural gas to produce aromatic products such as triphenyl are:

① Not competing with platinum reforming, ethylene units, and catalytic cracking units for petroleum raw materials, but instead providing high-quality cracking materials (ethane, propane, and butane) for ethylene units, with good compatibility with refining enterprises.

② Due to the relatively cheap prices of low-carbon and low sulfur hydrocarbon resources such as natural gas, and the high added value of BTX and gasoline, converting natural gas into BTX and gasoline can effectively improve the economic benefits of China’s refining enterprises.

③ The market demand for BTX and gasoline products is high, and they can digest a large amount of low-carbon hydrocarbon by-products such as natural gas. Therefore, this technology may become an important way for refining enterprises to solve the problem of by-products such as natural gas.

④ The natural gas to BTX and gasoline technology uses zeolite molecular sieve catalysts, which are non-corrosive and pollution-free, and can be repeatedly regenerated and used. Except for the emission of flue gas containing CO2 during the catalyst’s charcoal regeneration process, there are no other three waste emissions. Simultaneously possessing strong sulfur and nitrogen resistance, it can omit the pre refining step of liquefied gas raw materials, simplify the process, and reduce investment. The fixed bed reactor used in the process operates at atmospheric pressure, with mature technology, low investment, and high safety.

Aromatization construction has porcelain like properties, high strength, high hardness, good thermal stability, water absorption rate <0.5%, and a sunlight absorption ratio of 0.93. The sunlight absorption ratio does not decay over time and has the same service life as buildings. Therefore, this project uses low-carbon hydrocarbon resources such as natural gas to prepare aromatic products such as triphenyl, which presents significant opportunities and has promising market prospects for the aromatic industry.

1.1.3 Technical analysis

The project adopts the national invention patent (patent application number: 2006100442996) to produce aromatized deep processing products, and the project is supported by China Petroleum Technology Research Institute and Northeast Petroleum University.

1.1.4 Advantageous conditions of project construction

(1) Policy advantages

Development orientation of fine chemical industry is clearly pointed out in the 14th Five-Year Development Plan for Petrochemical Industry of Jilin Province. Extending the fine chemical industry chain from solving the transition from zero to high-quality development. Traditional fine chemical industry should be further upgraded, to meet requirements of downstream manufacturing industry for high-performance, safety and green development, improve the product quality and grade, and develop toward specialty and refinement.

(2) Location advantages

Qianguo County is located in the central area of the three northeastern provinces and Inner Mongolia. From the perspective of China’s map, it is situated at the eye of the rooster and is a transportation hub and important node city in Northeast China. The county urban area is located in the same city as Songyuan urban area, connecting 8 cities and 14 counties, with a population of over 34 million. The domestic road network is well connected, with multiple national and provincial highways such as Daqing-Guangzhou Expressway, Hunchun-Ulanhot Expressway, and Mingshui-Shenyang Highway intersecting vertically and horizontally; The Changchun-Baicheng Railway runs through the entire area from north to south, and after the high-speed train accelerates, it only takes 50 minutes to drive from Changchun. The Songhua River and Nenjiang River waterways are unobstructed, and the Qian Gorlos waterway can directly connect to the Russian Port of Khabarovsk. Songyuan Chaganhu Airport is located within the county, connecting 9 large and medium-sized cities including Beijing, Shanghai, and Dalian, and has initially formed a 3D, fast, and diversified transportation system.

(3) Resource advantages

The Ulantuga Industrial Park has obvious resource advantages, with proven oil reserves of 30 million tons and natural gas reserves of 100 billionm³ in the area. The former large oil production plant natural gas joint gas station located in Ulantuga Town is the hub for the outward dispatch of natural gas in the nearby area. The imported natural gas pipeline (China-Russia East Line) passes through Ulantuga and has two gate stations in the industrial park, which can supply 1 millionm³ of natural gas per day. Meanwhile, Sinopec Northeast Oil and Gas Branch can also supply 300,000m³ of natural gas per day, providing sufficient oil and gas resources for the Park to meet the production needs of the project. The surrounding infrastructure of the project construction site is complete, with convenient transportation and relatively complete construction conditions.

(4) Park advantages

Qianguo County is adjacent to Daqing Oilfield, and Jilin Oilfield is located within its borders. Daqing Oilfield and Jilin Oilfield are the first and sixth largest oil fields in China, respectively, with a total oil and gas production of 47 million tons. Sinopec Northeast Oil and Gas Branch, Sinopec Northeast Oil and Gas Branch, Sinochem Group Changshan Chemical Co., Ltd., and PetroChina Pipeline Changchun Oil and Gas Branch have settled in China, with a strong industrial foundation.

1.2 Contents and scale of project construction

1.2.1 Construction scale

Annual production of 100,000 tons of aromatic products.

1.2.2 Construction contents

The total area of the project is 50,000 ㎡, with a building area of 35,000 ㎡. Production equipment will be purchased and three production lines will be installed. The overall layout of the project is divided into administrative office area, R&D area, living area, production area, storage area, etc. The main contents of the production area include: production workshop, auxiliary workshop, logistics warehouse, product warehouse, maintenance workshop, power distribution room, etc.

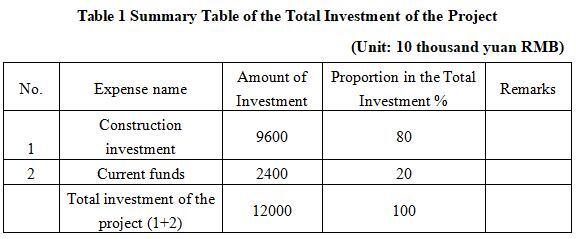

1.3 Total investment of the project and capital raising

The total investment of the project is 120 million yuan, including the construction investment of 96 million yuan.

1.4 Financial analysis and social evaluation

1.4.1 Main financial indexes

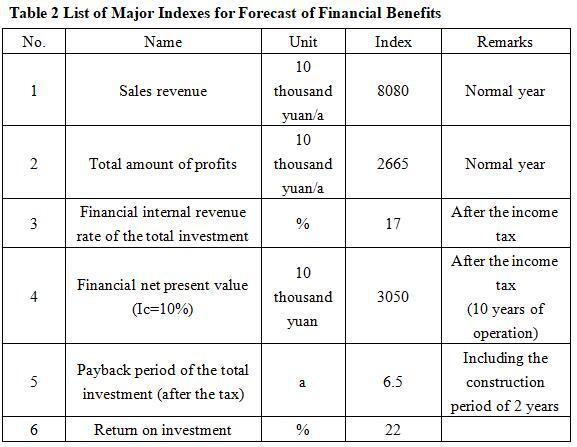

After the project reaches the production capacity, its annual sales revenue will be 80.8 million yuan, its profit will be 26.65 million yuan, its investment payback period will be 6.5 years (after the tax, including the construction period of 2 years) and its return on investment will be 22%.

Note: “10 thousand yuan” in the table is in RMB

1.4.2 Social evaluation

The project prepares green, low-carbon, ecological fine chemical products to make emissions cleaner, ecology lower carbon, and the environment more friendly. Meanwhile as the project construction, it will drive local employment, improve people’s living standards, and have a good promoting effect on the economic development and social harmony of Qianguo County.

1.5 Cooperative way

Sole proprietorship, joint venture and cooperation.

1.6 What to be invested by the foreign party

Funds, other ways can be discussed in person.

1.7 Construction site of the project

Ulantuga Industrial Park, Qianguo County

1.8 Progress of the project

The project proposal has been prepared

2. Introduction to the Partner

2.1 Basic information of unit

Name: Qianguo County Investment Promotion Service Center

Address: 909 Ulan Street, Qian Gorlos Mongolian Autonomous County, Songyuan City

2.2 Overview of unit

Qianguo County is the only Mongolian autonomous county in Jilin Province, covering an area of 6,980 km2. It governs 22 townships, 18 state-owned agriculture, forestry, animal husbandry, and fishing grounds, 233 villages, with a total population of 600,000. There are 25 ethnic groups including Mongolian, Han, Manchu, and Xibe. Where, the Mongolian population accounts for 11%. There are Qian Gorlosguan District, Chaganhu Tourism Economic Development Zone, Jilin Qian Gorlos Economic Development Zone, 4 municipal industrial parks, 2 county-level industrial parks, and 2 municipal animal husbandry parks in the county. There are five state-owned enterprises, including PetroChina Northeast Oil and Gas Branch, Sinopec Northeast Oil and Gas Branch, Sinochem Group Changshan Chemical Co., Ltd., China Datang Group Changshan Thermal Power Plant, and PetroChina Pipeline Changchun Oil and Gas Transportation Branch.

Chagan Lake, one of the top ten freshwater lakes in China, has a total area of 500 k㎡. It is a national Level AAAA tourist attraction, a national nature reserve, and a national water conservancy scenic spot. The Songhua River and Nenjiang River flow through the territory for 93 km, with an annual transit volume of 36 billionm³. The county currently has 4.8 million mu of arable land, which is rich in grain crops such as corn, rice, and miscellaneous grains. It is a national key commodity grain production base county and the only international green industry demonstration zone in Jilin Province. It has been designated by the provincial government as the “first demonstration county to achieve full mechanization of grain production” and has been awarded the “National Advanced County in Grain Production” for several consecutive years. Its grain output has always remained among the top ten grain producing counties in the country. The forest area is 2.2 million mu, with a forest coverage rate of 21.8%. It is one of the top 100 counties for afforestation in China and a demonstration county for ecological construction in Jilin Province. The grassland covers an area of 2.7 million mu, among which the best-preserved primitive grassland is 88 miles long and 40 miles wide, with an annual output of 180,000 tons of high-quality grass and 1.2 million sheep and 160,000 cattle. It is a national level grassland construction base county and a high-quality fine wool sheep production base county. The mineral resources are very abundant, with proven oil reserves of 320 million tons, natural gas reserves of 100 billionm³, and considerable reserves of oil shale, bentonite, purple clay pottery, etc.

2.3 Contact method

Contact unit: Qianguo County Investment Promotion Service Center

Contact: Li Xiaochun

Tel: +86-13351556769+86-0438-5098098

E-mail: zsjxmk2209905@163.com

Contact person of the city (prefecture) where the project is located:

Contact unit: Songyuan Municipal Commerce Bureau Investment Attraction Service Center

Contact person: Yu Lili

Tel: +86-18004388787