Petrochemical

20,000 Tons/Year of Coatings Project of Yanbian Prefecture

1. Introduction to the Project

1.1 Project background

1.1.1 Introduction to the Project

The project is located in the Tumen Chemical New Materials Circular Economy Industrial Park, with an annual production capacity of 20,000 tons of automotive coatings related production equipment and supporting facilities. The raw materials required for the project have sufficient supply in the domestic market, making procurement relatively convenient and transportation costs low.

The main product of this project is high-performance environmentally friendly coatings. These coatings are characterized by environmental friendliness, low carbon emissions, and high efficiency, and are widely used in various fields such as construction, automobiles, ships, bridges, and furniture. The specific product types include but are not limited to water-based coatings, powder coatings, high solid content coatings, etc. These coatings have excellent weather resistance, corrosion resistance, decorative and environmental performance, which can meet the needs of different customer groups. This project will ensure the quality and stability of coating products Through advanced production processes and equipment, providing the market with high-quality and high-performance coating products.

1.1.2 Market prospect

(1) Application and advantages of coatings

Paint, also known as coating, is a material that is applied to the surface of an object to form a coating, providing protection, decoration, and other special functions. It is widely used in various industries such as construction, transportation, and home furnishings. According to different purposes, coatings are divided into architectural coatings, industrial coatings, general coatings, and auxiliary materials; According to their different functions, they are divided into anti-corrosion coatings, waterproof coatings, and insulation coatings, etc.; According to their morphological differences, coatings can be divided into solvent-based coatings, water-based coatings, powder coatings, and solventless coatings. Solventless coatings themselves contain a small amount of solvent, which reacts with film-forming substances during the coating process to form coating components. Coatings are processed from film-forming substances, dispersing media, pigments, fillers, and additives according to specific formulas. The product quality mainly depends on the design of the formula, the accuracy of the feeding ratio, and the degree of dispersion and stirring. The film-forming substances are mainly natural resins and synthetic resins; The dispersion medium is mainly organic solvents or water; The main functions of pigments and fillers are decoration and filling, and the main substances include titanium dioxide and iron red; Additives are generally synthetic materials such as surfactants, which play a role in wetting, defoaming, and bonding in coating production.

(2)Market prospects of the project

From the perspective of demand structure, industrial coatings belong to the coatings industry and are one of its important components. Paint is a general term for a type of liquid or solid material that can form a solid coating film with protective, decorative, or special properties (such as insulation, anti-corrosion, labeling, etc.) on the surface of an object. It is an important engineering material for the national economy. In recent years, with the development of industries such as real estate, automobiles, ships, furniture, home appliances, containers, bridges, steel structures, rail transit, and new energy, the market has experienced significant growth and production has also increased.

According to relevant data, the operating revenue of China’s paint industry in 2022 was 452.5 billion yuan, with a year-on-year decrease of 5.2%. From the perspective of market distribution, the operating revenue of China’s paint industry in 2023 was 404.48 billion yuan, with a year-on-year decrease of 4.5%. Where, civil coatings account for about 45%, which was 180-billion-yuan, wood coatings (including furniture and home decoration) accounted for 20 billion yuan, sand powder and other base and auxiliary materials accounted for about 55 billion yuan, and building coatings accounted for about 105 billion yuan.

In terms of specific product types, the market performance of engineering coatings was also quite significant. In 2023, the revenue of interior and exterior wall engineering coatings was estimated to be around 65 billion yuan. Furthermore, factors such as intensified market competition in the paint industry, weak real estate market, insufficient domestic demand, and rising production costs have led to many paint companies facing growth pressure and bankruptcy risks. In the first half of 2024, China’s paint industry produced 17.556 million tons, with a year-on-year increase of 2%; The main business revenue was 19.063 million yuan, with a year-on-year increase of 0.4%.

In recent years, with the continuous improvement of environmental protection requirements by the country and the accelerated transformation and upgrading of the coating industry, the market demand for environmentally friendly coating products has been growing. Fenzi Group keeps pace with the times, actively responds to the national “14th Five-Year Plan” development plan, increases investment in scientific research and technological transformation, optimizes product structure, and promotes industrial upgrading. The construction of the new project will introduce advanced production equipment and processes, use environmentally friendly raw materials, reduce pollutant emissions from the source, and achieve clean production. With the rapid development of the global photovoltaic industry, the demand for solar silver paste has also shown explosive growth. With the rapid rise of the new energy vehicle market, the demand for high-performance and environmentally friendly automotive coatings is increasing day by day. The production of automotive silver paste, as an important component of the project, continuously meets the demand of domestic and foreign automotive manufacturers for high-quality coatings.

1.1.3 Technical analysis

Process design: After developing the coating formula in the laboratory, process design needs to be carried out according to production requirements, including the selection and layout of production equipment such as reaction vessels, grinders, mixers, and the determination of reaction conditions; Equipment procurement and installation: According to the process design requirements, purchase corresponding equipment and carry out installation and commissioning; Raw material procurement and storage: According to the production formula, purchase raw materials and store them in designated storage areas; Production process: According to the process flow, raw materials are weighed, added, mixed, and ground to prepare automotive coatings; Product testing: Conduct quality testing on the prepared coatings, including indicators such as color, drying time, hardness, adhesion, etc.; Packaging and Storage: Load the paint into buckets, label and store it. It should be noted that the production process of automotive coatings requires strict environmental protection requirements, and the production process needs to treat exhaust gas, wastewater, etc. to ensure minimal impact on the environment. Meanwhile, the production of automotive coatings requires strict control of param such as temperature, pressure, and time during the production process to ensure the quality and performance of the coatings.

The coating production technology used in this project mainly includes the following:

Firstly, for the production of water-based coatings, advanced emulsification and dispersion technologies are used to ensure that the pigments and fillers in the coating can be evenly dispersed in the aqueous phase, thereby improving the stability of the coating and the glossiness of the coating film. Meanwhile, we have also introduced environmentally friendly additives such as thickeners, dispersants, defoamers, etc. to further enhance the performance and environmental indicators of the coating.

Secondly, the production of powder coatings relies on precise powder processing technology. We use advanced grinding and grading equipment to process raw materials such as pigments and resins into uniform and fine powder particles. In the preparation process of powder coatings, attention is also paid to controlling the particle size distribution and flowability of the powder to ensure the spraying effect of the coating and the adhesion of the coating film.

For the production of high solid content coatings, we have used efficient solvent recovery technology and low volatile organic compound (VOC) formula design. By precisely controlling the amount of solvent and recovery efficiency, it is possible to minimize VOC emissions while ensuring coating performance, thus meeting the requirements of environmental regulations.

Furthermore, this project also introduces automated production lines and intelligent control systems to achieve continuous and automated production of coatings. These advanced production technologies and equipment not only improve production efficiency and reduce production costs, but also ensure the quality and stability of coating products, meeting the market’s demand for high-quality and high-performance coatings.

1.1.4 Advantageous conditions of project construction

(1) Policy advantages

At the level of industrial policy. The 14th Five-Year Plan for Industrial Green Development clearly states that we will vigorously develop and promote new energy vehicles, and promote the promotion of alternative fuel vehicles such as methanol vehicles. Continue to promote green and intelligent home appliances such as high-efficiency lighting, energy-saving air conditioning, energy-saving refrigerators, and water-saving washing machines through methods such as “trade in”. Encourage the use of coatings and cleaning agents with low volatile organic compound content, and accelerate the development of new building materials such as biomass, wood, and gypsum. Increase the proportion of recycled material consumption. By 2025, 10,000 types of green products will be developed and promoted.

(2) Location advantages

Tumen is a port city located on the eastern border of Jilin Province, with characteristics of being along the border, along the river, along transportation lines, and near the sea. Tumen City is located at the junction of the Tumen River Basin and the Golden Triangle proposed by the United Nations Development Programme. It is an important transportation hub and distribution center for people, logistics, and commerce in Northeast Asia in the future. Tumen City is located between Yanji City and Hunchun City, forming a horn like relationship with Hunchun Development Zone. It is a direct channel for Jilin Province’s opening up to the outside world, with a strategic position of connecting the east and the west, as well as strong radiation, connection, and distribution functions. The transportation is very convenient, with the Changchun Yanji Hunchun Expressway crossing the southern end of the development zone. It is only three km away from Tumen Railway Freight Station, Passenger Station, and China North Korea International Railway and Highway Bridge. It’s only a 30-minute drive from Yanji Airport.

(3) Basic advantages of the project

This project is planned to be constructed in the Tumen Chemical New Materials Circular Economy Industrial Park, with a total planned area of 2.89 k㎡, flat terrain, convenient transportation, and the Mudanjiang- Tumen Railway running through the entire area. The infrastructure is fully equipped, the sewage treatment plant has been basically completed, the Energy and Power Center is about to start construction, and the resource conditions required for production are relatively complete. The key development of the Park focuses on new material chemical industry, which combines emerging industries such as fine chemical and applied chemical with low pollution, low energy consumption, and high added value. By adopting a unique industrial model of chemical material processing, the Park can undertake the transfer of chemical industry from regions such as Beijing-Tianjin-Hebei and the Yangtze River Delta, and build an industrial chain and cluster with distinct circular economy characteristics.

1.2 Contents and scale of project construction

The project covers a total area of 50 mu and includes the construction of one comprehensive building, one pump room, two production auxiliary rooms, two Class A warehouses, one Class C warehouse, two production workshops, one Class A tank area, and other production auxiliary facilities, with an annual production capacity of 20,000 tons of paint.

1.3 Total investment of the project and capital raising

The total investment of the project is 160 million yuan, including the construction investment of 128 million yuan.

1.4 Financial analysis and social evaluation

1.4.1 Main financial indexes

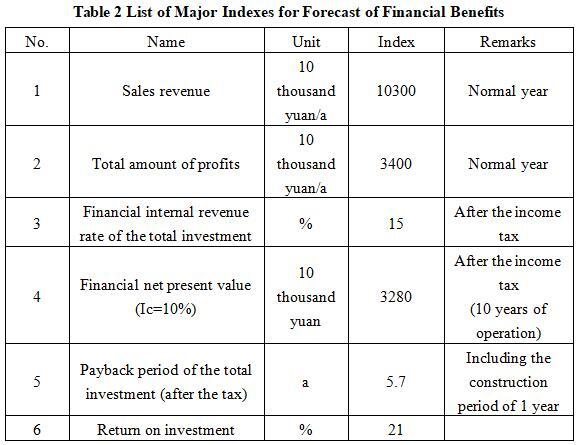

After the project reaches the production capacity, its annual sales revenue will be 103 million yuan, its profit will be 34 million yuan, its investment payback period will be 5.7 years (after the tax, including the construction period of 1 year) and its return on investment will be 21%.

Note: “10 thousand yuan” in the table is in RMB

1.4.2 Social evaluation

The social benefits of coatings are mainly reflected in environmental protection, energy conservation, and industry promotion.

Environmental protection: Coatings have significant benefits in social and environmental protection. The use of low volatile organic compound (VOC) coatings can reduce air pollution and protect the atmosphere. Reasonable use of coatings can avoid pollution to water bodies and reduce noise pollution through mechanized production. Furthermore, strengthening the recycling of coatings can reduce waste emissions and thus lower the impact on the environment.

Energy conservation: The production process of coatings requires a large amount of energy consumption, which puts pressure on local energy supply and generates carbon emissions. Energy-saving measures can be taken to reduce the negative impact on the environment, such as using solar energy, waste heat recovery and other technologies, and promoting new energy to replace traditional energy.

Industry promotion: The role of the coatings industry in driving social and economic development cannot be ignored. With the rapid development of the social economy, the variety of coatings is constantly updated, from traditional oil-based and water-based coatings to high-performance coatings, meeting various application needs. The production of China’s coatings industry has significantly increased, making it a leader in the global coatings market and enhancing its international status.

1.5 Cooperative way

Sole proprietorship, joint venture and cooperation.

1.6 What to be invested by the foreign party

Funds, other ways can be discussed in person.

1.7 Construction site of the project

Tumen Chemical New Materials Circular Economy Industrial Park

1.8 Progress of the project

The project proposal has been prepared

2. Introduction to the Partner

2.1 Basic information of unit

Name: Jilin Tumen Border Economic Cooperation Zone

Address: 688 Fengwu Road, Tumen Economic Development Zone, Jilin Province

2.2 Overview of unit

Tumen City is located between longitude 129 ° 39’ and 130 ° 46’ east and latitude 42 ° 46’ and 43 ° 43’ north. It is a port city on the eastern border of Jilin Province, with characteristics of being along the border, along the river, along transportation lines, and near the sea. Tumen City is located at the junction of the Tumen River Basin and the Golden Triangle proposed by the United Nations Development Programme. It is an important transportation hub and distribution center for people, logistics, and commerce in Northeast Asia in the future.

Tumen City belongs to the temperate zone with a humid and mild climate. Influenced by the Sea of Japan, the temperature difference between winter and summer is small, with no extreme heat in summer and no severe cold in winter. The annual average temperature is 15C, and the annual rainfall is 540 mm. It has a frost-free period of 135 days throughout the year. The Tumen Economic Development Zone has a suitable climate, convenient transportation, abundant water, electricity, and coal energy, complete communication facilities, good geological structure, and excellent hydrology and engineering geology, making it an ideal industrial land for start-up and construction.

2.3 Contact method

Contact unit: Jilin Tumen Border Economic Cooperation Zone

Project contact person: Lyu Yunpeng

Tel: +86-13274337733

Fax: +86-433-3957020

E-mail: tmjjkfq@126.com

Contact method of the city (prefecture) where the project is located:

Contact unit: Yanbian Prefecture Commerce Bureau

Contact person: Li Jingyu

Tel: +86-13596515933