Hydrogen Energy

The 600,000 Tons/Year Green Hydrogen from Biomass Project of Jilin City

1. Introduction to the Project

1.1 Project background

1.1.1 Product introduction

Hydrogen production from biomass mainly refers to the technology of converting biomass into hydrogen through chemical or biological methods after a series of pretreatment. Compared to other hydrogen production methods, hydrogen production from biomass not only provides stable and abundant hydrogen energy support for the development of modern society, but also efficiently converts various agricultural and household wastes into high value-added resources, thereby achieving the resource utilization of wastes. This technology not only helps promote the development of green energy, but also has profound significance for environmental protection and sustainable development.

The project utilizes the abundant biomass resources in Panshi City, Jilin Province to produce green hydrogen and methanol. After the project is completed, it will produce green hydrogen and green methanol at 600,000 tons/year. Green hydrogen and green methanol will be used as fuels for automobiles and other equipment within Jilin Province.

1.1.2 Market prospect

(1) Market demand for hydrogen energy

Hydrogen, as one of the most important elements on Earth, mainly exists in its chemical form. Its elemental form, hydrogen, is a clean and efficient energy carrier. In recent years, with the increasing global demand for clean energy, hydrogen and its related technologies have received widespread attention. Especially in the context of carbon peaking and carbon neutrality, hydrogen, as a secondary clean energy, is regarded as the “Ultimate Energy of the 21st Century”.

In recent years, China’s hydrogen energy industry has received high attention from governments at all levels and key support from national industrial policies. According to statistics, in 2024, a total of 22 provincial-level administrative regions in China included hydrogen energy in their government work reports, and each region actively developed hydrogen energy from different focuses. Since 2024, China has issued a large number of policies at the national level in the hydrogen energy industry, covering many aspects such as industry standard setting, technology R&D, equipment promotion, urban public transportation updates, and hydrogen energy transportation, aiming to promote the healthy, orderly, and sustainable development of the hydrogen energy industry.

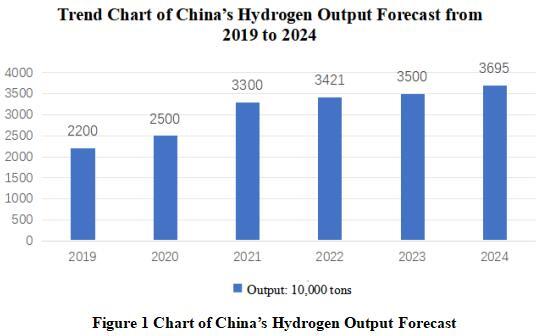

Under the dual promotion of policies and market, China has become the world’s largest country of hydrogen production. As of the end of 2023, the national hydrogen production capacity has been about 49 million tons/year, with an output of about 35 million tons, an increase of about 2.3% year-on-year. In 2024, China’s hydrogen output reached 36.95 million tons.

Under the goal of carbon neutrality, the annual demand for hydrogen in China will have reached 37.15 million tons by 2030, accounting for about 5% of terminal energy consumption. By 2060, the annual demand for hydrogen in China will have increased to around 130 million tons, accounting for about 20% of terminal energy consumption. Among them, the hydrogen consumption in the industrial field still accounts for the largest proportion, accounting for 60% of the total demand.

The hydrogen production processes mainly include hydrogen production from water electrolysis, hydrogen production from fossil energy, hydrogen production from chemical raw materials, and biological hydrogen production, etc. The technology of hydrogen production from water electrolysis has the advantages of simple process, low environmental pollution, and high hydrogen purity. However, water electrolysis requires a large amount of electricity and expensive catalysts, making it difficult to ensure the economical efficiency. From the current share of hydrogen production, hydrogen production from fossil energy still accounts for about 50% of the total industrial hydrogen production. European and American countries mainly use natural gas for hydrogen production, while China mainly uses coal gasification for hydrogen production. However, this method sacrifices fossil energy and the hydrogen production efficiency is less than 60%, which urgently requires technological progress. Methanol and other chemical raw materials can undergo cracking reactions to produce hydrogen under certain temperature, pressure, and catalyst conditions. This method has a simple process, stable operation, high efficiency, and environmental protection. However, the cost of hydrogen production is greatly affected by the industrial raw material methanol, and the hydrogen production process relies on catalysts. Therefore, it is necessary to reduce catalyst costs and improve catalytic stability.

Biological hydrogen production mainly involves converting light energy and organic matter stored in nature into hydrogen through microbial physiological metabolism. According to different microbial species and metabolic mechanisms, biological hydrogen production is mainly divided into three types: hydrogen production from water photolysis, hydrogen production from photo fermentation, and hydrogen production from dark fermentation. Compared to other hydrogen production methods, the advantages of biological hydrogen production include: ①It has lower reaction cost and less stringent reaction conditions, and can be carried out under room temperature and pressure; ② It does not consume fossil fuels, produce less pollutants, and can reuse living organisms, being an excellent renewable method; ③ The substrate sources are abundant, usually requiring light energy and organic matters, which can be widely sourced from solar energy, food processing wastewater, industrial organic wastewater, agricultural waste, etc., having improved the energy utilization efficiency.

From a global perspective, currently, various countries mainly produce hydrogen through processing petrochemical raw materials, while green hydrogen produced from wind energy, solar energy, water electrolysis, and biomass, etc. accounts for less than 1% of the total output. Among them, production capacity of biological hydrogen is less than 1% of green hydrogen, and the development of biomass hydrogen energy is still in its infancy.

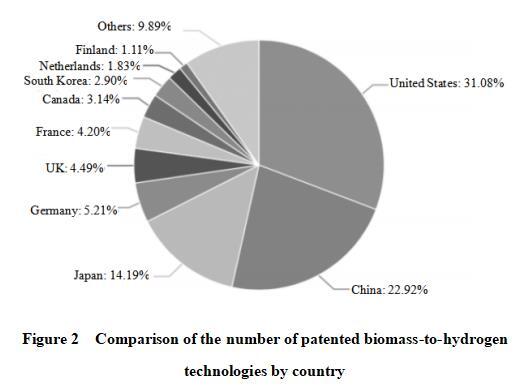

Although China’s technology of hydrogen production from biomass started relatively late, it has developed rapidly in recent years and has great potential for development. According to statistics, the United States, China, and Japan account for 68% of the global patent technology of hydrogen production from biomass, with China ranking second with about 23% of the total patents and possessing the mainstream patent technology. Since2015, China’s annual patent application volume has surpassed that of the United States, ranking first in the world and gradually widening the gap with other countries.

Biomass, as an environmentally friendly renewable energy resource, if its hydrogen production technology can be industrialized, it will have a positive impact on improving energy utilization structure, controlling environmental pollution, and addressing climate change. By now, hydrogen production from biomass is still in the early stage of germination, among which the technology of thermo-chemical hydrogen production from biomass is relatively mature. Although it can be used for large-scale production, the hydrogen production rate is not high. With the vigorous development of hydrogen energy by the country, hydrogen production from biomass will become the focus of achieving large-scale production of green hydrogen in the future, especially in areas rich in biomass, where hydrogen production from biomass will have enormous development potential and prospect.

(2) Current market situation of green methanol

As of June 27, 2024, there have been total 102 green methanol projects planned globally, with a total planned production capacity of 13.27 million tons/year. Most projects are still in the research and planning stage, with 11 projects in operation, 5 projects under construction, 13 projects under planning, and 73 projects in the announcement or feasibility stage. Seeing from the distribution in countries, Spain, Denmark, and the United States are the three countries with the highest number of green methanol projects, with 13, 10 and 10 projects, respectively. In terms of technical route, the project of methanol production from electricity is in the dominant position, followed by the project of methanol production from biomass.

China is the world’s largest consumer and producer of methanol. In 2023, the total methanol production capacity of methanol was 105 million tons, accounting for nearly 60% globally. Despite China’s vast industrial system and huge domestic demand for methanol, it still relies on imports, with an estimated import volume of about 14.55 million tons in 2023. In 2024, there was an increase of about 5 million tons of production capacity, with the total production capacity reaching 112 million tons and the output of about 92.57 million tons. In 2025, it is expected to have an increase of 8.9 million tons of production capacity, of which 5.8 million tons of supporting olefin, 1, 4-butanediol (BDO) and other devices, and 3.1 million tons of non-integrated devices. In 2024, the import volume of methanol was 13.31 million tons, down 7.33% year-on-year, and it is expected to rise again to more than 14 million tons in 2025.

Green methanol, as a low-carbon fuel, has great potential in fields such as automobile fuels, fuel cells, ship fuels, and organic additives. The International Maritime Organization (IMO) has adopted relevant emission reduction strategies to promote the application of green methanol in ship fuel. In addition, the production cost of green methanol is gradually decreasing, and with the reduction of green electricity costs and the expansion of production scale, its economy will be further improved.

1.1.3 Technical analysis

(1) Hydrogen production from biomass

By isolating the air during the first pyrolysis, the volatile substances that make up the majority of the raw materials are transformed into a gaseous state; Remove the residual charcoal and perform secondary high-temperature cracking on the gas products, cracking heavy hydrocarbons (tar) with higher molecular weight into gases such as hydrogen and methane, and completely eliminating the tar; Reform the pyrolysis gas to convert methane and carbon monoxide (CO) into hydrogen; The produced hydrogen rich gas can be directly used in high-temperature carbonate and other types of fuel cells, becoming an efficient and clean distributed power generation system, or using pressure swing adsorption (PSA), membrane separation technology, etc. to separate pure hydrogen.

(2) Methanol production from hydrogen

Methanol production from hydrogen is a chemical reaction that synthesizes methanol through hydrogen and CO under the action of catalyst(s). This reaction is usually carried out under certain temperature and pressure conditions, typically in an environment of 200-300 ℃ and 20-30 MPa. Common catalysts include copper-zinc-aluminum catalysts, copper-aluminum catalysts and copper-chromite catalysts, which have high catalytic activity and stability, and can efficiently promote the synthesis reaction of methanol.

(3) Synthesis

Considering the instability of renewable electricity and to facilitate load regulation, methanol synthesis is considered in 2series, each with a capacity of 300,000 tons/year.

The purified synthesis gas is mixed with hydrogen to obtain fresh gas at a pressure of 1.5 Mpa. It is compressed to 7.4 MPa by a synthesis gas compressor and then further compressed to 8.0 MPa by mixing with circulating gas before entering the methanol synthesis tower. Methanol products are obtained from crude methanol after dehydrogenation and dehydration.

1.1.4 Advantageous conditions of project construction

(1) Policy advantages

In 2025, the National Energy Administration issued the Guiding Opinions on Energy Work in 2025, proposing that we should adhere to green and low-carbon development, and continue to promote the adjustment and optimization of the energy structure. We should give priority to ecological and green development, and work together to reduce carbon emissions and pollution and promote green growth. We should vigorously develop renewable energy, coordinate the local consumption and delivery of new energy, strengthen the clean and efficient development and utilization of fossil energy, actively promote energy conservation and carbon reduction on the energy consumption side, accelerate the transformation of energy consumption patterns, and increase the proportion of non-fossil energy consumption.

The 14th Five-Year Plan for Industrial Development in Jilin Province clearly proposes to promote the development of hydrogen energy equipment and hydrogen fuel cells around the entire industrial chain of hydrogen “production, storage, transportation, refueling and utilization”. Support the RD of intelligent heat exchange units and new high-efficiency energy-saving heat exchangers. Accelerate the development of environment-friendly equipment such as air pollution control, water pollution control, and solid waste treatment. Cultivate new energy system solution suppliers, and establish RD and manufacturing bases of new energy equipment.

The Mid- and Long-term Development Plan of a Hydrogen-powered Jilin (2021-2035) proposes to make the hydrogen energy industry a key focus for cultivating and developing strategic emerging industries. Based on the chemical industry in Jilin City, Baicheng City, and Songyuan City, we should carry out demonstrations of “Green Chemical Industry in Jilin” (hydrogen-based chemical industry) projects, build diversified hydrogen energy supply, carbon fiber material and other industry auxiliary systems, and expand the business scope of the chemical industry.

The Investment Promotion Policy of Jilin City clearly states that the investment projects of Jilin Industrial Investment Guidance Fund should comply with national and relevant industrial policies and development plans, with a focus on investing in tourism, medicine and health, aviation, information technology, new materials, advanced equipment manufacturing, biotechnology, energy conservation and environmental protection, new energy, cultural creativity, modern agriculture, modern service industry and other related industries in Jilin City’s “6411” industrial plan, as well as other areas supported by the municipal government for development with focus. In addition to setting up sub-funds through equity participation, the Guidance Fund can also adopt investment methods such as follow-up investment and direct investment; Newly introduced investment projects that meet the conditions shall enjoy tax reductions and exemptions in accordance with the current national and provincial tax policies. For projects with a significant contribution rate in Jilin City, in accordance with the spirit of the document Notice of the State Council on Relevant Matters Concerning Tax Preferential Policies (GF[2015] No. 25), relevant departments shall assist the enterprises in applying for tax exemptions and reductions in accordance with the law and regulations; Establish a special fund for the development of industrial enterprises, and encourage the introduction of major projects in traditional industries such as chemical, automobile, metallurgical, and agricultural product processing in the “6411” industrial system that comply with national industrial policies, have strong industrial support, and have a significant driving effect; Encourage the introduction of emerging industries such as medicine and health, new materials, advanced equipment manufacturing, and electronic information. Lay emphasis on the allocation of production factors, and give priority to recommend relevant national and provincial special funds for support.

(2) Resource advantages

The biomass production in Jilin City mainly includes agricultural residues such as crop straw and rice straw, with a total amount of 5.89 million tons. After deducting agricultural return to field, livestock feed, rural cooking, heating and other purposes, the surplus amount of straw biomass resources that can be collected is 2.67million tons. The straw output in Panshi City exceeds 1.2398 million tons.

The available land area in Jilin City is 853 hectares, including 74 hectares of commercial land, 500 hectares of industrial and mining storage land, 179 hectares of residential land (including guaranteed land for affordable housing), and 100 hectares of other land (including land for public management and public services, transportation, water bodies and water conservancy facilities, and special land). There is a large stock of exploitable land resources, and newly added and reserved land can meet the needs of new projects. Land prices are at a low level among 41 cities in Northeast China.

(3) Talent advantages

Jilin City has universities such as Northeast Electric Power University, Jilin General Aviation Vocational and Technical College, Jilin Technology College of Electronic Information, Jilin Vocational College of Industry and Technology. These universities provide a continuous stream of talent support for enterprises. These talents not only possess rich practical experience, but also have high technical level and innovation ability. They are able to solve various technical problems in the production process, and improve the production efficiency and product quality. Meanwhile, these professional skilled talents can actively participate in the technological innovation and product research and development work of the enterprises, providing strong guarantees for the sustainable development of the enterprises.

Meanwhile, Jilin City has a large number of high-quality industrial workers. After training by enterprises and public welfare institutions, more than 10,000 skilled talents are sent to the society every year, and more than 20,000 people of various types are trained for the society every year. The advantage of labor resources is obvious, and the proportion of skilled workers is at a high level in the Northeast urban agglomeration. The labor force is in a dividend period, and the labor cost is relatively low, which can meet the needs of various enterprises.

(4) Location advantages

Jilin City is located in the central eastern part of Jilin Province, is adjacent to Yanbian Korean Autonomous Prefecture to the east, Changchun City and Siping City to the west, borders Harbin City, Heilongjiang Province to the north, and borders Baishan City, Tonghua City and Liaoyuan City to the south.

Jilin City is located at the geographical center of Northeast Asia, with various forms of transportation including railways, highways, water transportation, and aviation, etc. The artery traffics such as Jilin Longjia International Airport and Jilin Airport, Changchun-Hunchun and Shenyang-Harbin Expressways, Changchun-Hunchun Intercity Express Railway, and Shenyang-Harbin Double-track Railway form a convenient three-dimensional transportation network extending in all directions in Jilin City.

1.2 Contents and scale of project construction

1.2.1 Construction scale

The total area of the project is 600,000 square meters. After completion, the project will utilize biomass to produce green hydrogen and green methanol at 600,000tons/year.

1.2.2 Construction contents

The total construction area of the project is 470,000 square meters, mainly consisting of high-temperature gasification furnace, catalytic furnace, purification workshop, facilities for synthesis, storage and transportation of methanol, and supporting facilities, etc.

1.3 Total investment of the project and capital raising

1.3.1 Total investment of the project

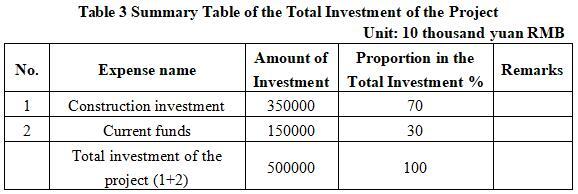

The total investment of the project is 5,000 million yuan, including the construction investment of 3,500 million yuan, and current funds of 1,500 million yuan.

1.3.2 Capital raising

Raised by the enterprise itself.

1.4 Financial analysis and social evaluation

1.4.1 Main financial indexes

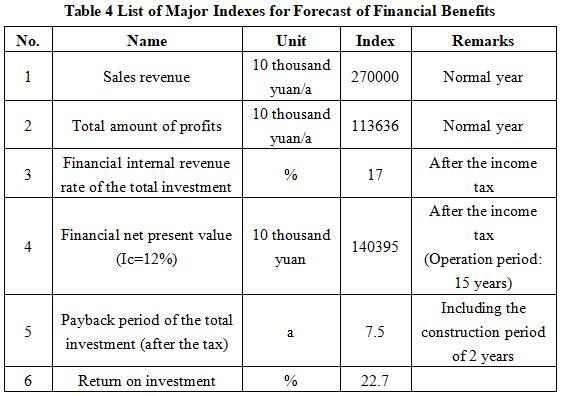

After the project reaches the production capacity, its annual sales revenue will be 2,700 million yuan, its profit will be 1,136.36 million yuan, its investment payback period will be 7.5 years (after the tax, including the construction period of 2 years) and its return on investment will be 22.7%.

Note: “10 thousand yuan” in the table is in RMB

1.4.2 Social evaluation

As part of the Green Hydrogen project, this project will help promote the transformation of energy structure from traditional fossil fuels to clean energy, reduce the reliance on fossil fuels, lower greenhouse gas emissions, and combat climate change.

The construction of the project will also drive the development of related industrial chains, including collection, processing, and transportation of biomass, as well as the production, storage, and application of green hydrogen, creating employment opportunities for the local area and promoting economic growth.

1.5 Cooperative way

Joint venture or cooperation, other ways can be discussed in person.

1.6 What to be invested by the foreign party

Funds, other ways can be discussed in person.

1.7 Construction site of the project

Panshi Metallurgical Chemical New Materials Industrial Park in Jilin Panshi Economic Development Zone.

1.8 Progress of the project

It is in planning phase.

2. Introduction to the Partner

2.1 Basic information

Name: Jilin Panshi Economic Development Zone Management Committee

Address: Jilin Panshi Economic Development Zone

2.2 Overview

Panshi Metallurgical Chemical New Materials Industrial Park was established in 2019, and was recognized by the Provincial Chemical Industrial Park Office in late 2020 and September 2023, respectively; In 2022, its safety risk level assessment was recognized as level C by the Department of Emergency Management of Jilin Province. There are currently 13 enterprises, including 3 industrial enterprises of designated size. The park is accelerating the construction of infrastructure and supporting facilities, providing a good development platform for enterprises entering the park; With the goal of supplementing, strengthening, and extending the supply chain, the park will attract excellent businesses and select suitable resources, while promoting the project to reach the production capacity and efficiency early, and creating a new growth pole for the Panshi industrial economy. It strives to have built a green and low-carbon “ten billion level” park by 2025.

2.3 Contact method

Contact method of the unit where the project is located:

Contact unit: Jilin Panshi Economic Development Zone Management Committee

Postal code: 132000

Contact person: Sun Kai

Tel: +86-432-65257806

+86-13252559898

Contact method of the city (prefecture) where the project is located:

Contact unit: Investment Promotion Service Center, Bureau of Commerce of Jilin City

Contact person: Jiang Yuxiu

Tel: +86-432-62049694

+86-15804325460

E-mail: jlstzcjfwzx@163.com