Hydrogen Energy

Longi Songyuan Hydrogen Energy Industrial Park (Green Hydrogen-Methanol Integration) Project of Songyuan City

1. Introduction to the Project

1.1 Project background

1.1.1 Product introduction

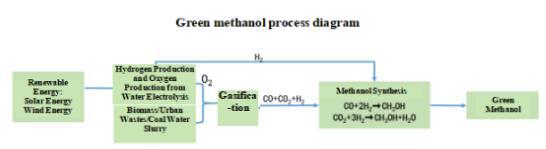

The project consists of three core modules on the whole: wind and solar energy storage power station, hydrogen production from alkaline water electrolysis, and green methanol. Production from green hydrogen coupled biomass. This project fully utilizes the abundant wind solar and biomass resources in the region, using agricultural waste as raw material, and adopting green methanol production technology with independent intellectual property rights and a series of efficient catalysts. We have innovatively developed biomass gasification production equipment and green methanol production equipment, and ensured that the entire production process uses green electricity to produce green methanol.

The project plans to produce 400,000 tons/year of green and low-carbon methanol. In addition, by vigorously developing the green methanol industry at the local level, it aims to form a development pattern of industrial linkage and work together with upstream and downstream enterprises to build a green methanol ecosystem. This will promote the local consumption of new energy and drive the high-quality development of local green and low-carbon economic industries, committed to building the region into an important national energy and strategic resource base.

1.1.2 Market prospect

(1) Project background

With the increasingly severe global climate change problem, governments and enterprises around the world have gradually recognized the importance of green hydrogen and begun to invest funds and technology in its research & development and application. At the beginning of the 21st century, green hydrogen technology gradually matured, but its high cost limited its commercial application development. However, with the continuous progress of technology and the reduction of cost, the green hydrogen industry is gradually emerging. Since the release of the Medium and Long-term Plan for Hydrogen Energy Industry Development (2021-2035) at the national level, various regions have actively planned for hydrogen (green hydrogen) production from renewable energy. According to the corresponding hydrogen energy policy plans issued by local governments, the total planned green hydrogen production capacity will have reached 1 million/1 million/2.5 million tons by 2025/2030/2035. The current domestic policy planning areas are all concentrated in the Three North areas (Northeast, North and Northwest China) with abundant wind and solar resources. Among them, Inner Mongolia’s planned capacity for 2025 will reach 500,000 tons/year, accounting for half of the total plan for that year, being a key area for promoting green hydrogen nationwide. The large-scale development will drive down the cost of hydrogen production from renewable energy and promote the continuous improvement of electrolyzer technology.

With the extensive development of oil and coal, the reserves of non-renewable resources are becoming increasingly scarce, thus the development of new energy has been raised to a strategic level. New energy sources such as solar energy, wind energy, and green hydrogen will be widely developed in the near future. With the acceleration of the localization process of new energy, the price of new energy will further decrease, and the competitiveness of new energy will be greatly strengthened. The development of green hydrogen and green methanol can save a lot of fuel resources and improve the regional energy structure.

Green hydrogen refers to hydrogen produced through renewable and clean energy sources such as solar energy, wind energy, and nuclear energy. Its typical production process involves generating hydrogen through electrolysis of water driven by renewable energy power generation. Due to the negligible carbon emissions during this process, this hydrogen is endowed with the characteristics of “zero carbon” or “carbon free”, thus being widely recognized by the industry as a sustainable and environmentally friendly energy carrier - zero carbon hydrogen.

The goal of “carbon peaking and carbon neutrality” proposed by General Secretary Xi Jinping is a major strategic decision made by the Party Central Committee. It is not only a goal to address climate change, but also a strategic goal for economic and social development, reflecting the value direction of China’s future development. It has profound and significant implications for building a new development pattern with domestic circulation as the mainstay and domestic and international circulations mutually promoting each other. It is a major political task. Meanwhile, General Secretary Xi Jinping proposed a new energy security strategy of “four revolutions and one cooperation”, which has pointed out the direction for China’s energy development and opened up a new path for the development of energy with Chinese characteristics. We should follow General Secretary Xi Jinping’s ecological civilization ideology, actively address the global climate change problems caused by carbon emissions, steadfastly promote green development, accelerate the construction of a clean, low-carbon, safe and efficient energy system, continue to promote carbon emission reduction, and lead global governance actions.

(2) Project prospect

Green methanol produced using renewable energy is considered an ideal alternative fuel. As an important component of basic chemical products, methanol has a global annual consumption of 126 million tons and an industry output value exceeding 300 billion yuan. In recent years, the application of methanol in the field of alternative fuels has been increasing. However, traditional methanol mainly relies on fossil fuels such as coal or natural gas as raw materials, resulting in high carbon emissions, especially in China, where methanol production mainly relies on methanol production from coal. With the global implementation of long-term net zero emission policy, the methanol industry is facing significant transformation. The green methanol industry based on production from renewable energy is accelerating its development. Green methanol refers to methanol produced from renewable energy such as biomass, captured carbon dioxide, and green hydrogen. Its entire life cycle can achieve near zero emissions and significant environmental benefits.

Assuming that all methanol consumption in China will be supplied by methanol production from electricity in the future, the demand for green hydrogen will reach about 21 million tons, which is equivalent to 41 times the current output of green hydrogen in China. Correspondingly, the demand for green electricity may exceed 1 trillion kilowatt hours, equivalent to 68% of the country’s new energy power generation capacity in 2023.

The global shipping industry is facing enormous decarbonization pressure, and the route of methanol production from biomass has shown good economic performance. According to the International Maritime Organization’s forecast, by 2050, the market share of traditional fossil fuels in the shipping industry will have decreased to 15%, and the utilization rate of green methanol will gradually increase to 42%. At that time, the demand for green methanol in the shipping industry is expected to have reached 190 million tons. In recent years, the number of operating ships and orders using methanol as fuel has continued to grow, and relevant policies and supporting facilities are also gradually being improved. In order to encourage the supply of green methanol with biomass as the carbon source that meets EU standards, international shipping giants have signed high priced biomass green methanol supply contracts with multiple new energy companies, providing a sufficient guarantee for the profitability of biomass methanol route.

Longi Green Energy Company plans to invest in the construction of a Green Methanol Production from Wind and Solar Hydrogen Storage Integration Project in Songyuan City, in order to further promote the green and low-carbon transformation of energy in the region, accelerate the development of the clean energy industry, and help achieve the “carbon peaking and carbon neutrality” goals. The construction of this project will ensure the smooth progress of subsequent new projects and contribute more to the local economy.

The construction of this project is in line with the development plan of renewable energy and the development direction of the national energy industry, and is conducive to optimizing the local energy structure; it can fully utilize the abundant local wind and solar energy resources to alleviate energy pressure; it can increase the proportion of local renewable energy and reduce environmental protection pressure; it can promote technological progress in the industry of green methanol production from wind and solar hydrogen storage, and promote sustainable development of local national economy. The construction of the project has good environmental, social, and political benefits.

The project location has abundant wind and solar energy resources, broad development prospect, convenient transportation, and superior construction conditions. After engineering estimation and financial analysis, the project has good economic benefits. Therefore, the construction of this project is feasible both economically and technically.

1.1.3 Technical analysis

The target product of this project is green methanol, with renewable biomass as the raw material. As the raw material of this project is solid biomass, solid gasification is used to produce gas. The gas quality is adjusted through partial transformation, and some CO2 and impurities that have a toxic effect onthe catalyst are removed through purification and decarbonization processes. Then, green hydrogen is partially coupled to adjust the components of the fresh gas to meet the working conditions required for methanol synthesis. The fluctuation and scale of raw material composition, change in flow rate of coupled green hydrogen will affect the selection of these process units.

After the biomass circulating fluidized bed atmospheric pressure gasification is partially coupled with green hydrogen, the selection of process route and catalyst can be referred to the process of methanol production from natural gas.

The overall process route of green methanol production from biomass atmospheric pressure gasification coupled with green hydrogen is described as follows:

Biomass raw materials from outside the boundary are transported by conveying machinery into the gasification unit, where they undergo gasification reactions with oxygen from the air separation unit and steam produced as a byproduct of gasification in the circulating fluidized bed. The resulting crude synthesis gas is buffered in a dilute oil and gas tank before entering the crude desulfurization unit to remove most of the H2S impurities contained in the synthesis gas. Afterwards, the synthesis gas is divided into two streams and sent to the power island as fuel for the gas turbine, while the remaining majority of the crude synthesis gas enters the fine desulfurization unit. The synthesis gas from the fine desulfurization unit enters the transformation unit for partial transformation, with a part entering the decarbonization unit, while the other route without decarbonization. The flow rate of the synthesis gas is controlled by a regulating valve, and it merges with the decarbonized synthesis gas before entering the methanol synthesis unit.

The 1.5 MPa green hydrogen from outside the boundary enters the synthesis unit and couples with fresh gas. After the purified synthesis gas entering methanol synthesis is pressurized to 6 MPaG, it reacts in the synthesis unit to generate methanol. The synthesis tail gas is sent to the circulating gas compressor for pressurization to 7.5MPa before being recycled. The crude methanol in the synthesis unit is subjected to segmented distillation in the methanol distillation unit to obtain industrial grade methanol product.

1.1.4 Advantageous conditions of project construction

(1) Policy advantages

The European Union (EU) is committed to having achieved climate neutrality goal by 2050 and promoting accelerated carbon reduction in various industries through a series of policy measures. For example, the EU has launched the “Fit for 55” package climate policies, including sustainable maritime fuels, the EU Emissions Trading System Directive (EUETS), and the Renewable Energy Directive (RED III), which have driven the demand for green methanol.

The project complies with relevant policy requirements such as the National 14th Five-Year Plan and 2035 Development Plan, the Opinions of the Central Committee of the Communist Party of China and the State Council on Fully, Accurately and Comprehensively Implementing the New Development Concept and Doing a Good Job in Carbon Peak and Carbon Neutrality, the Notice of the State Council on Issuing the Action Plan for Carbon Peak before 2030, the Medium- and Long-Term Plan for the Development of the Hydrogen Energy Industry (2021-2035), the 14th Five-Year Plan for Energy Development in Jilin Province, the Implementation Opinions on Supporting Green and Low Carbon Development and Promoting Carbon Peak and Carbon Neutrality, and the Implementation Plan for the “Hydrogen-powered Jilin” Action. In addition, Jilin Province has also introduced several policy measures to support the development of the hydrogen energy industry, encouraging the construction of the integrated demonstration project for renewable energy hydrogen production and green hydrogen self-consumption, and provided support in project approval, energy-saving review, and other aspects.

These policy measures together constitute the policy framework for supporting the development of green and low-carbon methanol projects in Jilin Province, aimed at promoting the green and low-carbon transformation of the energy system, industrial structure, production and lifestyle, and promoting the development and application of renewable energy such as methanol.

(2) Industrial advantages

Songyuan City has abundant renewable energy resources, such as solar energy and wind energy, which provide sufficient energy input for the production of green methanol.

The Songyuan Municipal Government actively promotes the development of green and low-carbon industries, attracting more enterprises to invest in green and low-carbon projects through measures such as investment attraction and policy service guarantees. For example, the Songyuan Municipal Government has visited relevant enterprises for multiple times to discuss cooperation projects and promote the implementation of green hydrogen-based chemical projects and green electricity pure hydrogen metallurgical high-purity iron projects.

The green methanol project can not only produce methanol, but also produce by-products such as oxygen and sulfur, which can be further used in other industrial production, forming a complete industrial chain and improving resource utilization efficiency.

The development of green and low-carbon methanol projects in Songyuan City has multiple advantages, including resources, technology, market demand, policy support, and a complete industrial chain. These advantages will help Songyuan City achieve greater development in the green and low-carbon field.

The Jilin Songyuan Petrochemical Industry Circular Economic Park is dominated by industries such as petrochemicals, natural gas chemicals, fine chemicals, biochemistry, and modern logistics. It gradually extends the industrial chain, develops end products, and increases added value. The park is equipped with facilities such as a research center, pilot and standardized factories, a small and medium-sized enterprise incubation center, a warehousing and logistics park, and a comprehensive service center, etc., providing convenient conditions for settled enterprises.

(3) Location advantages

The Jilin Songyuan Petrochemical Industry Circular Economic Park is located in the southeast of Songyuan City, Jilin Province, on the south bank of the Songhua River, adjacent to National Highway 302 and the Daqing-Guangzhou Expressway, with outstanding transportation advantages. The park has abundant water resource, and is equipped with profound chemical industrial foundation, where, Jilin Oilfield is headquartered in Songyuan City, with many backbone enterprises distributing evenly surrounding the park.

The park is adjacent to the National Highway 302 and Daqing-Guangzhou Expressway, with convenient transportation, which is conducive to logistics transportation and regional economic connections. In addition, the park has two dedicated railway lines, with an annual cargo shipping capacity of up to 6 million tons, further improving the logistics efficiency of the park.

(4) Talent advantages

Songyuan City has established 11 industrial colleges, scientific research internship and training bases, and doctoral workstations to support rural revitalization with 7 provincial universities including Jilin University and Jilin University of Finance and Economics. These cooperations have attracted a large number of high-level talents and college graduates to come to Songyuan for scientific research, study, work, and living. It has established a “Talent Home · Project Special Class” and connected 126 industrial projects and 83 talent projects. Through the integration platform of industry and talents, it has attracted a large number of high-level talents, which can provide sufficient talent support for the project.

1.2 Contents and scale of project construction

The planned land area is 1,400 mu, including 500 mu for the green methanol project, 300 mu for hydrogen production and storage, and 600 mu for biomass warehousing.

The green methanol production from green hydrogen coupled biomass project covers an area of 500 mu (chemical land in the chemical park), and the chemical park needs to have seven supplies and one leveling or nine supplies and one leveling. The green energy planning and site selection required for green methanol supporting facilities are divided into three parts: wind power site selection, PV site selection, and energy storage. The planning includes 850 MW wind power site selection and 350 MW PV project site selection, which are synchronized with supporting electrochemical energy storage. The preliminary plan for the total installed capacity of the project is 1,200 MW. After completion, the project can achieve an annual power generation of 3.2 billion kWh, providing green power guarantee for hydrogen production from water electrolysis.

The hydrogen production and storage project covers an area of approximately 300 mu (industrial/chemical land), mainly for the construction of facilities for hydrogen production from water electrolysis and oxygen production, buildings such as factories, warehouses, office buildings, laboratories and control rooms, as well as environmental protection, fire protection, safety and other supporting facilities and public utilities. The project has an annual hydrogen production capacity of 54,000 tons/year and a rated hydrogen production capacity of 90,000 Nm/h.

The biomass warehousing project covers an area of 600 mu and utilizes the abundant biomass resources in the area, such as wheat and corn straws, corn cobs, pruned branches of fruit trees, forestry wastes, tree roots, wood processing wastes, and livestock manure, etc. It produces green methanol from partial coupling of biomass circulating fluidized bed constant pressure gasification with green hydrogen. The demand for biomass is not less than 500,000 tons/year (within a range of 100 kilometers, with a moisture content of less than 20%). After the completion of the project construction, it can achieve an annual production of 400,000 tons of green methanol.

1.3 Total investment of the project and capital raising

The total investment of the project is 8,300 million yuan, including the construction investment of 6,000 million yuan.

The investment in wind and solar power plants, energy storage equipment, and external transmission lines is about 5.5 billion yuan, the investment in hydrogen production from water electrolysis is 800 million yuan, and the investment in green methanol production equipment is 2 billion yuan.

1.4 Financial analysis and social evaluation

1.4.1 Main financial indexes

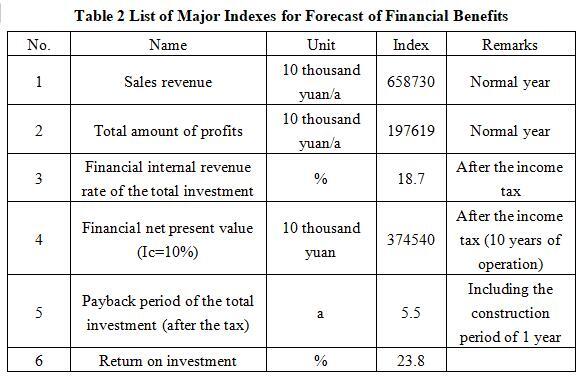

After the project reaches the production capacity, its annual sales revenue will be 6,587.30 million yuan, its profit will be 1,976.19 million yuan, its investment payback period will be 5.5 years (after the tax, including the construction period of 1 year) and its return on investment will be 23.8%.

Note: “10 thousand yuan” in the table is in RMB

1.4.2 Social evaluation

The project fully utilizes the advantages of wind and solar energy resources in the region, and generates clean energy (green hydrogen) from clean energy, greatly reducing greenhouse gas emissions such as carbon dioxide. It can reduce carbon dioxide emissions by 1.2 million tons/year and indirectly consume 4 million tons of carbon dioxide, which is equivalent to increasing forest planting area by 800 square kilometers.

Compared to traditional fossil fuel power generation, the green methanol production from wind and solar hydrogen storage integration project does not produce air pollutants such as sulfur dioxide, nitrogen oxides, and particulate matter, effectively reducing the level of air pollution.

The construction of the project can not only drive economic growth in related industries of new energy construction and chemical fields, such as building materials, steel, engineering construction, and chemical transportation, but also drive the growth of production in surrounding office and life related industries. It will play a significant role in expanding employment and developing the tertiary industry. After being put into operation, the income from hydrocarbon derivatives such as power generation, green hydrogen, and green methanol will increase, and local tax revenue, public facilities will be improved, and living welfare will be enhanced.

The construction of the green methanol production from wind and solar hydrogen storage integration project has optimized the energy structure, increased energy supply, and is bound to establish a favorable hard economic development environment. In a favorable hard environment, it will inevitably promote the rapid development of related industries, thereby driving and promoting the comprehensive development of the regional national economy and social progress, opening up new growth points for the local economy, and driving the development of the local economy.

Promote the development of new energy in rural areas: Introduce new energy technologies such as wind power and PV power generation into rural areas, utilize vast rural land resources and natural conditions, build wind power and PV power plants, and provide clean energy supply. This can not only meet the energy needs of rural areas, but also provide additional economic income for local farmers and promote the development of rural economy. It can solve the environmental protection treatment problem of 700,000 tons of animal husbandry wastes or 500,000 tons of agricultural straw treatment problems for the local area.

Increasing the re-employment of labor force, the methanol factory is expected to have 420 employees; The collection, storage, transportation, and supporting services will indirectly drive employment for over 800 people throughout the entire industrial chain; Benefiting local farmers and village collectives.

1.5 Cooperative way

Sole proprietorship, joint venture and cooperation.

1.6 What to be invested by the foreign party

Funds, other ways can be discussed in person.

1.7 Construction site of the project

Jilin Songyuan Petrochemical Industry Circular Economic Park

1.8 Progress of the project

The project proposal has been prepared

2. Introduction to the Partner

2.1 Basic information of unit

Name: Longi Green Energy Technology Co., Ltd.

Address: No. 388 Hangtian Middle Road, Chang’an District, Xi’an City

2.2 Overview of unit

Enterprise profile:

Longi Green Energy Technology Co., Ltd. (hereinafter referred to as “Longi Green Energy”), founded in 2000, is committed to becoming the world’s most valuable solar energy technology company. Longi Green Energy takes “making good use of the sun light to create a green energy world” as its mission, adheres to the brand positioning of “steady and reliable, and technology-led”, focuses on technological innovation, and builds five business segments: monocrystalline silicon wafers, battery modules, distributed PV solutions, ground PV solutions, and hydrogen energy equipment, forming the ability to support global zero carbon development with “green electricity” + “green hydrogen” products and solutions.

Longi Green Energy has established multiple production and manufacturing bases in countries and regions such as China, Vietnam, and Malaysia, and has set up branch offices in countries such as the United States, Japan, Germany, India, Australia, the United Arab Emirates, and Thailand. Its business covers more than 150 countries and regions worldwide. Longi Green Energy has joined the RE100, EP100, and EV100 initiatives, setting scientific carbon targets (SBTi), continuously promoting green and sustainable development, supporting the global energy revolution, and contributing to the construction of a “zero carbon earth” and “green earth”.

Longi believes that the best product warranty is “the lifespan of the enterprise should be greater than the lifespan of the product”, maintaining a leading financial health level in the industry and working hand in hand with customers and partners for a long time. In 2022, the total assets were 143.874 billion yuan, with an annual revenue of 128.998 billion yuan, and cash and cash equivalents of 54 billion yuan. Stable financial data provides reliable financial support for project investment.

Longi Green Energy has proposed the “Solar for Solar” model and the “Longi LIGHT” sustainable development concept, and is the only Chinese company that has joined the RE100, EV100, EP100, and the “Science-based Targets initiative (SBTi)” international initiative simultaneously. While creating low-cost clean energy for the world, we also practice the concept of green and low-carbon production and manufacturing, achieving the production of clean energy with clean energy.

Adhering to the core values of “reliability, value-added, and pleasure”, Longi Green Energy will promote the widespread application of the “green electricity+green hydrogen” system solution worldwide, allowing more people to enjoy green energy and contribute to the green and low-carbon energy transformation process.

Longi was founded in 2020 and achieved an annual production capacity of 30 tons of silicon rods in 2005; In 2014, the sales volume of monocrystalline silicon wafers ranked first in the world; it entered the field of battery components in 2015 and became the world’s top exporter of monocrystalline battery components; In 2021, Longi successfully achieved the world’s top supplier in terms of production capacity and annual output of silicon wafers, batteries, and components.

In 2022, the global production capacity of monocrystalline silicon wafers was150 GW, the battery capacity was 60GW, and the module capacity was 85 GW. The global shipment volume of monocrystalline silicon wafers was 85.06 GW, ranking first in the world in terms of shipment volume; For three consecutive years, its shipment volume of monocrystalline modules has ranked first in the world.

Longi has established production and manufacturing bases in countries and regions such as China, Vietnam, and Malaysia, and set up branch offices in Europe, America, the Middle East, Africa, and Asia Pacific, etc. Its business covers more than 150 countries and regions. In 2023, the global planned production capacity for monocrystalline silicon wafers was 190 GW, for solar cells it was 110GW, and for modules it was 130 GW.

Longi’s breakthroughs are endless. From April 2021 to April 2023, Longi Green Energy broke the world record for battery conversion efficiency for 15 times in different technological routes, and the HJT efficiency breakthrough record was maintained by Longi, breaking the five-year world record for crystalline silicon cell efficiency. This was a milestone in the development history of China’s PV industry.

Park Overview:

Jilin Songyuan Petrochemical Industry Circular Economic Park (referred to as Songyuan Petrochemical Park) is a provincial-level industrial park approved by the Jilin Provincial Government in October 2011. It is located in the southeast of Songyuan City, with a total planned area of 23.2 square kilometers. The park is led by high-tech and circular economy, with a focus on developing the petroleum and natural gas chemical, fine chemical, and biochemical industries, gradually extending the industrial chain, developing end products, and increasing added value.

Historical background and major achievements of the park:

Since its establishment, Songyuan Petrochemical Park has achieved many important achievements:

In April 2017, it was designated as a national industrial transformation and upgrading demonstration park.

In April 2021, it was approved as a demonstration zone for “green power” in Songyuan, with a green power supply area of 7.71 square kilometers.

In September 2021, the chemical industrial park was recognized as a C-level general safety risk level by the Department of Emergency Management of Jilin Province.

In November 2022, it successfully passed the C-level safety risk assessment review by the Department of Emergency Management (Emergency Department).

In September 2023, the Green Chemical Industrial Park was successfully recognized as a chemical park by the Department of Industry and Information Technology of Jilin Province.

Infrastructure and public services of the park:

Songyuan Petrochemical Park has complete infrastructure and public service facilities:

Transportation: There are dedicated railway lines, road networks, etc. within the park, with an annual cargo shipping capacity of up to 6 million tons.

Water and power supply: It has the municipal Jiangnan water supply plant, park sewage treatment plant, and substation, etc., which can meet the production needs of projects entering the area.

Other facilities: They include research centers, pilot and standardized factories, small and medium-sized enterprise incubation centers, warehousing and logistics parks, and comprehensive service centers.

Future development plan and goals of the park:

Under the strategic background of “carbon peaking and carbon neutrality”, Songyuan Petrochemical Park undertakes the important task of “revitalizing market with industry, and strengthening market with energy”. In the future, the park will continue to leverage the competitive advantages of “green electricity” consumption and “six new” industries, build industrial systems such as green chemicals, new energy, and new materials, and make every effort to build the Songyuan Green Petrochemical Industrial Base, promoting high-quality regional economic development.

2.3 Contact method

Contact person of the city (prefecture) where the project is located:

Contact unit: Songyuan Municipal Commerce Bureau Investment Attraction Service Center

Contact person: Yu Lili

Tel: + 86-18004388787