Automobile and Parts

Lithium Battery Recycling and Utilization Project of Changchun City

1. Introduction to the Project

1.1 Project background

1.1.1 Product introduction

As a key component of new energy vehicles, power batteries account for 30% to 40% of the cost of the whole vehicle. Under normal use conditions, the service life of a battery is usually 5 to 8 years, and when its capacity drops below 80% of its initial capacity, it needs to be retired. Retired batteries can be downgraded and used in different fields such as backup power, electric two-wheelers, small energy storage devices, etc. For batteries that cannot be used in cascades, they will be crushed and refined to produce precious metals such as lithium, cobalt, and nickel through recycling, so as to realize the recycling of resources.

The project is located in Changchun Kuancheng Economic Development Zone, aiming to reduce environmental pollution and promote the recycling of resources through scientific and reasonable recycling methods. The precious metals in waste batteries can be reused for battery manufacturing or other industrial purposes after being recycled, thus achieving the dual goals of resource conservation and economic benefits.

1.1.2 Market prospect

(1) Analysis of the current situation of lithium battery recycling and reuse

With the rapid development of new energy vehicles and energy storage industry, the demand for lithium batteries has increased significantly, and correspondingly, the number of retired batteries has also increased sharply. According to relevant statistics, in 2024, the retirement of power batteries in China was about 20.2 GWh, an increase of 48.53% over the previous year; the number of retired new energy vehicles was about 402900, a year-on-year increase of 46.56%. Looking ahead to 2030, the number of retired batteries and new energy vehicles is expected to increase to 148.7 GWh and 2.9891 million respectively. This trend indicates that the recycling and disposal of waste lithium batteries will face severe pressure and challenges.

Lithium battery recycling technology is constantly making progress, mainly using wet process for dismantling and recycling. This technology involves pretreatment of dismantled waste batteries and dissolving them in strong acid or alkali solutions, and extracting valuable metal elements from them by methods such as ion exchange and electrodeposition. In addition, cascade utilization has also become an important recycling strategy, that is, waste batteries with high residual capacity are used in scenarios such as energy storage and backup power supply for communication base stations.

The government has issued a number of policies to support the development of the lithium battery recycling and reuse industry, such as the Industry Standard Conditions for the Comprehensive Utilization of Waste Power Batteries for New Energy Vehicles. These policies aim to regulate industry behavior and promote technological innovation and capacity expansion. In recent years, many enterprises have increased technological innovation and expanded production capacity, and have obtained more than hundreds of millions of yuan in financing support.

Although the lithium battery recycling and reuse industry faces challenges in the construction of recycling networks, uneven technical levels and insufficient policy support, with the continuous progress of technology and the continuous promotion of policies, the recycling efficiency is expected to be further improved, and the market size will also be expanded. It is estimated that by 2025, the total amount of retired power batteries in China will reach 137.4 GWh, and the total amount of waste batteries that need to be recycled will reach 960000 tons; by 2030, the size of the power battery recycling market alone is expected to reach about 140 billion yuan.

(2) Prospect analysis of lithium battery recycling and reuse

In recent years, with the continuous improvement of scientific and technological level, power battery recycling technology is also constantly advancing. Waste lithium battery crushing and sorting equipment is also constantly reducing costs and increasing efficiency, from the early coarse and bulky to the intelligent and efficient sorting; it greatly improves the recovery rate of waste lithium batteries and the purity of valuable metal battery powder. In addition, some new intelligent discharge technologies have also been applied to battery recycling, further improving recycling efficiency and reducing production costs.

With the continuous expansion of the electric vehicle market, the demand for power batteries is also growing. It is expected that by 2030, the market size of retired power batteries will reach hundreds of billions of yuan. This huge market demand will bring huge market opportunities and development space for the development of the power battery recycling industry.

Nevertheless, the power battery recycling industry is still facing many challenges. First of all, the upgrading of recycling technology requires a large amount of capital investment, which is a big test for startups. Secondly, the environmental issues in the recycling process cannot be ignored, and how to reduce environmental pollution in the recycling process is an important issue that the industry needs to solve. Furthermore, the recycling and disposal of waste batteries requires the establishment of a complete logistics system, which increases the operating costs to a certain extent.

However, with the continuous advancement of technology and the gradual improvement of policies, these issues are expected to be solved. For example, through government subsidies and tax incentives, the economic pressure on enterprises can be reduced and more enterprises can be encouraged to invest in the power battery recycling industry. At the same time, by establishing industry standards and norms, enterprises can be guided to adopt more environmentally friendly and efficient recycling technologies, thus realizing the sustainable development of the industry.

In addition, the improvement of public awareness of environmental protection also provides new opportunities for the development of the power battery recycling industry. With the increasing attention of people to environmental protection, the recycling and utilization of waste batteries will be supported and participated by more people. Therefore, by strengthening publicity and education, raising public awareness of the importance of waste battery recycling, the market base for power battery recycling can be further expanded.

In summary, the development of the power battery recycling industry has broad prospects, but at the same time, it is also facing many challenges. Only through the joint efforts of the government, enterprises, and the public can efficient recycling and resource utilization of power batteries be achieved, contributing to the construction of a green and low-carbon future.

1.1.3 Technical analysis

Power battery recycling and treatment technology mainly includes cascade utilization and dismantling utilization. Cascade utilization is mainly aimed at batteries that have been decayed to the point that they cannot be used normally on new energy vehicles, and these batteries themselves are not scrapped and can continue to be used. Dismantling and utilization is to decompose the battery, extract the important metal components in it, and recycle these metal components.

In terms of dismantling and utilization, the recycling and treatment technologies mainly include mechanical sorting, high-temperature pyrolysis and hydrometallurgical methods. The mechanical sorting method is mainly to separate the metal shell and electrode material in the battery by mechanical means. The high-temperature pyrolysis method is to use high temperature to pyrolyze battery materials to separate the valuable metals in them. The hydrometallurgical method is used to recover valuable metals such as lithium, cobalt, and nickel through steps such as crushing, dissolution, leaching, and separation.

For the material treatment in the recycling process, there are also mainly physical recycling, chemical recycling and biological recycling processes. The physical recycling method mainly separates and sorts the battery materials through physical means to extract the valuable metals in them. The chemical recycling method mainly uses chemical reactions to convert valuable metals in battery materials into soluble compounds, and then separates and recovers. The biological recycling technology uses microbial leaching to convert the useful components of the system into soluble compounds and selectively dissolve them, so as to realize the separation of target components and impurity components, and finally recover valuable metals such as lithium, cobalt and nickel.

1.1.4 Advantageous conditions of project construction

(1) Policy advantages

The Interim Measures for the Management of Recycling and Utilization of Power Batteries for New Energy Vehicles stipulates that producers, sellers and users of power batteries shall assume the responsibility for recycling, and clarifies the qualification requirements and management procedures of recycling and utilization entities. The implementation of these policies has provided strong support and guarantee for the development of the power battery recycling industry.

In order to promote the recycling and utilization of lithium batteries, the Chinese government has issued a series of relevant policies, established a complete lithium battery recycling system, and promoted the healthy development of the lithium battery recycling and utilization industry.

The National Development and Reform Commission, the Ministry of Industry and Information Technology, and the Ministry of Ecology and Environment jointly issued the Guiding Opinions on Promoting the Recycling and Utilization of Lithium Batteries, proposing to accelerate the construction of a lithium battery recycling and utilization system, strengthen the supervision of lithium battery recycling and disposal, and promote the recycling and utilization of lithium battery resources. The following policy measures are proposed:

Encourage enterprises to carry out lithium battery recycling and utilization. Establish and improve the mechanism for enterprises to fulfill their producer responsibilities, and promote enterprises to carry out lithium battery recycling and disposal business; promote technological innovation in lithium battery recycling. Support the research and development of lithium battery recycling technology to improve recycling efficiency and resource utilization; strengthen regulation and law enforcement. Improve the supervision system for lithium battery recycling and disposal, and strengthen the supervision and management of lithium battery recycling enterprises; encourage the reuse of lithium batteries. Support the development of the lithium battery reuse industry and promote the recycling and utilization of lithium battery resources.

(2) Location advantages

Kuancheng District has a superior geographical location and is the core hinterland of the new city in the north of Changchun City. It is located at the intersection of the Harbin-Dalian first-level axis and the main axis of the Changchun-Jilin-Tumen Pilot Zone. The Beijing-Harbin Railway divides Kuancheng into two parts, Tienan and Tiebei. Tienan Area is one of the most prosperous business districts in Changchun City, where a number of large-scale commercial and wholesale enterprises gathers; Tiebei Area is an old industrial base of Changchun, with a strong industrial foundation and industrial advantages. In addition, Kuancheng District is adjacent to Changchun New Area in the east and large central enterprises such as Railway Vehicles Co., Ltd. in the west, and is in the core area of the western industrial corridor in the city's planning and layout, and has unique advantages in future industrial development.

(3) Industrial advantages

The Development Strategic Plan for Changchun Kuancheng Economic Development Zone (2020-2035) and the Outline of the 14th Five-Year Plan for Changchun Kuancheng Economic Development Zone have determined the construction of a new development pattern focusing on rail transit equipment and automotive parts, with food processing, resource recycling, new energy, new materials, biomedicine, urban agriculture and automotive aftermarket services as the characteristic industries, creating a distinctive logo of Changchun Kuancheng Economic Development Zone.

(4) Talent advantages

As the core area in the north of Changchun, the development zone actively builds an industry-university-research cooperation platform, attracts a large number of high-quality talents, and establishes a technological innovation system with enterprises as the main body, market as the guide, and the combination of industry, university, research and application. Talents from 42 universities in Changchun and in the region gather strongly to gather wisdom and strength for the development of the city. In addition, the Kuancheng District Government has signed a talent cooperation framework agreement with Jilin City Vocational and Technical College, Changchun College of Electronic Technology, and Jilin University of Architecture and Technology, providing talent support for the development of enterprises.

1.2 Contents and scale of project construction

1.2.1 Product scale

100000 tons of waste lithium batteries will be processed annually, 2 Gwh of lithium batteries in cascades will be produced, and 20000 tons of metal elements will be recycled.

1.2.2 Contents of project construction

The planned land area for this project is about 30000 square meters. The main construction includes lithium battery recycling workshops, retired lithium battery dismantling workshops, recycled lithium battery capacity reuse production workshops, physical (crushing) lithium battery workshops, and other ancillary facilities.

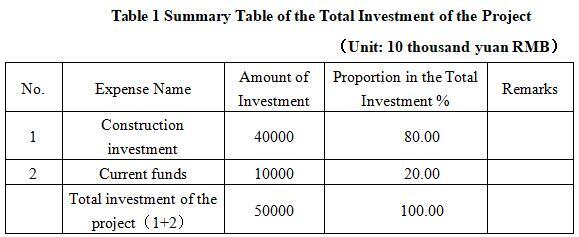

1.3 Total investment of the project and capital raising

The total investment of the project is 500 million yuan, including the construction investment of 400 million yuan.

1.4 Financial analysis and social evaluation

1.4.1 Main financial indexes

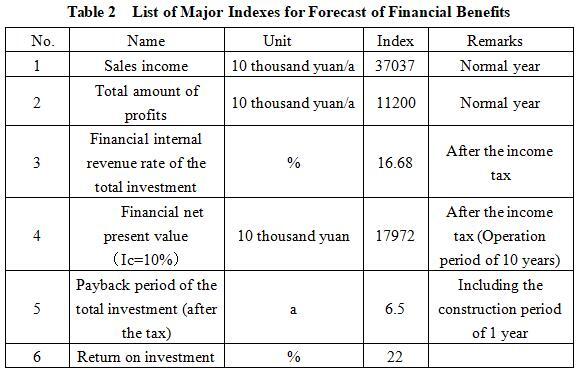

After the completion of the project, its annual sales income will be 370.37 million yuan, its profit will be 112 million yuan, its investment payback period will be 6.5 years (after the tax, including the construction period of 2 years) and its investment profit rate will be 22%.

Note: “10 thousand yuan” in the table is in RMB.

1.4.2 Social evaluation

The construction and operation of the project will create a large number of employment opportunities, including construction personnel, technical personnel, and management personnel. It is expected that 100 employment positions will be provided after the project reaches the production capacity. In addition, the project will also promote the development of the local industrial chain and drive employment growth in related industries.

1.5 Cooperative way

Sole proprietorship

1.6 What to be invested by the foreign party

Technology, design, construction and operation

1.7 Construction site of the project

Changchun Kuancheng Economic Development Zone

1.8 Progress of the project

The project proposal has been prepared

2. Introduction to the Partner

2.1 Basic information

Name: Changchun Kuancheng Economic Development Zone Management Committee

Address: No. 7388 North Kaixuan Road, Kuancheng District, Changchun City, Jilin Province

2.2 Overview

Changchun Kuancheng Economic Development Zone (formerly known as Changchun Changjiang Road Economic Development Zone) was established in 1998 with the approval of Changchun Municipal Party Committee and Municipal Government, and was promoted to a provincial-level development zone in 2001, covering an area of 115.16 square kilometers. The population in the area is about 220000, there are more than 10000 market entities of various types, and the total economic output accounts for more than 60% of Kuancheng District. After more than 20 years of development, the comprehensive development level has risen to the forefront of provincial-level development zones, and has gradually developed from a single commercial economic development zone to a comprehensive development zone dominated by railway vehicles, industrial manufacturing, modern logistics and commercial service industries, with the coexistence of multiple industries.

Changchun Kuancheng Economic Development Zone is located in the north of Changchun urban area, it faces the North Lake Science and Technology Development Zone of Changchun New Area across the river in the east, connects with the city center in the south, adjoins the Lvyuan District in the west, and connects with Nong'an County of Changchun in the north. It is about 13 kilometers away from the city center, and is about 30 kilometers away from Changchun Longjia International Airport. It is located at the core node of the priority development of Harbin-Dalian first-level axis in the national northeast revitalization plan, and is a key area for Kuancheng District to build a modern core area in the north. The main road network system of "three horizontals and four verticals" has been built, where the Beijing-Harbin Railway, Changchun-Baicheng Railway, Beijing-Harbin Expressway, Hunchun-Ulanhot Expressway, around-city highway, No. 102 National Highway, and No. 302 National Highway converge. The infrastructure in the area is complete, with water, electricity, gas, heat, communication and other functional supporting facilities fully completed, and public service functions such as schools, hospitals and parks are complete. It has superior ecological resources such as Yitong River, Jingshui River and Chuan Lake.

The "14th Five-Year Plan" development blueprint of Changchun Kuancheng Economic Development Zone has planned the spatial layout of "one city, two belts, four cores and five areas", and adopted the development model of "one zone and multiple parks". Focusing on the goal of building a demonstration zone for the integration of industry and city in the north of Changchun, it will focus on building a world-class rail equipment manufacturing and repair center and an ecological sightseeing and leisure center in the suburbs of the city. It determines the development pattern with rail transit as the leading industry, pan-traffic industry and professional logistics as the supplement, and featured food processing, resource recycling, new materials, clean energy, biomedicine, urban agriculture and automobile aftermarket services as the characteristic industries.

Projects located in Changchun Kuancheng Economic Development Zone not only enjoy provincial and municipal preferential policies, but also enjoy policy support of Kuancheng District. For industrial projects, investment subsidies will be given according to the type of industry and the funds in place; after the project reaches its production capacity, financial support will be given according to the output value and tax situation; for major projects, special policies will be given in accordance with the "one matter, one discussion" approach.

2.3 Contact method:

2.3.1 Contact information of project cooperation unit:

Contact unit: Kuancheng Economic Development Zone

Contact person: Zhang Junjie

Tel: +86-431-89991958 +86-13578763399

E-mail: 184479431@qq.com

2.3.2 Contact method of the city (prefecture) where the project is located:

Contact unit: Changchun Cooperation and Exchange Office

Contact person: Zhang Junjie

Tel: +86-15704317930

Fax: +86-431-82700590

E-mail: xmc82763933@163.com