Automobile and Parts

400000-set/year Aluminum Alloy Wheel Hubs Project of Liaoyuan City

1 Introduction to the Project

1.1 Project background

1.1.1 Product introduction

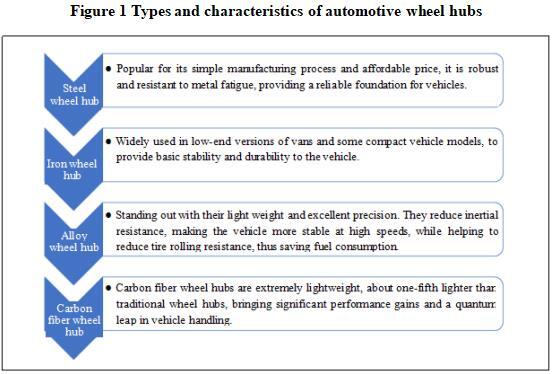

Wheel hub, as the main bearing part of the driving part of the vehicle, consists of rims, offsets, bead seats, rims, spokes, valve holes, groove bottoms and other components, and it is one of the most important safety components affecting the performance of the vehicle. The main function is to support the tire so that the vehicle can run smoothly.

Aluminum wheel hubs, also known as aluminum rims or aluminum wheel rollers, are wheel hubs made from less dense aluminum alloys as the material as the name suggests. The aluminum alloy materials used in the manufacture of aluminum wheel hubs include A356, 6061, etc. Among them, A356 is widely used for cast aluminum wheel hubs. A356 aluminum alloy has the characteristics of small specific gravity, good erosion resistance, etc., mainly composed of aluminum, silicon, magnesium, iron, manganese, zinc, copper, titanium and other metal elements, with aluminum accounting for about 92%, which is a technically mature aluminum alloy material.

The construction site of the project is located in Liaoyuan High-tech Industrial Development Zone, Jilin Province, and 400000 sets of automotive wheel hubs can be produced annually.

1.1.2 Market prospect

(1) Market prospect of automotive wheel hub

Automotive wheel hub is an important part of automotive wheel, which not only affects the appearance and performance of the automobile, but also directly relates to the safety and comfort of the automobile. With the continuous expansion of the automobile market and the diversification of consumer needs, the automotive wheel hub industry is also facing new opportunities and challenges.

With the continuous progress of automotive technology, the performance requirements for wheel hubs are getting higher and higher. Aluminum alloy wheel hubs have become the mainstream products in the market due to their lightweight, high strength and aesthetics, accounting for most of the market share. At the same time, with the enhancement of environmental awareness and the requirements of sustainable development, recycled materials and environmentally friendly wheel hubs are also gradually favored by the market.

Technological advancements have not only improved the performance of wheel hubs, but also increased their market attractiveness, thereby driving further expansion of the market size. The global automotive wheel hub market size reached 113.711 billion yuan in 2023. It is expected that by 2029, the global automotive wheel hub market will reach 158.861 billion yuan at a growth rate of 5.69%. The growth of the market size is mainly due to the increase in global automobile production and sales, and the increasing demand of consumers for automotive performance and appearance.

The Asia-Pacific region currently controls the largest share of the industry. One of the main factors influencing the growth of the region is the huge population of countries such as China and India, which account for more than 40% of the world's population. Its growth can be attributed to the changing tastes of people brought about by urbanization and rising disposable incomes, and the growth in automobile manufacturing is mainly due to the expansion of the automotive industry in South Korea, India, and China.

Europe has the second largest market share and may experience the highest compound annual growth rate throughout the forecast period. The reason behind this is that consumers prefer upgraded aluminum alloy wheel hubs as compared to traditional steel wheels.

North America has the third largest market share. The United States is in a leading position in manufacturing due to its large number of enterprises. Because the U.S. automobile market is currently operating in an environment of low inflation, low financing rates, and compliance with national economic standards, manufacturers must make significant investments. Standard steel wheels are more commonly used throughout the country.

(2) Current situation of aluminum automotive wheel hub market

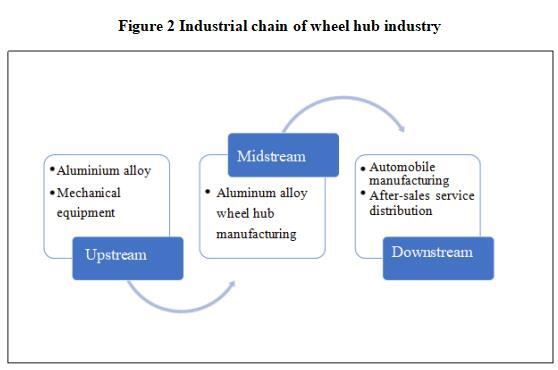

The industrial chain structure of the wheel hub industry includes upstream raw material suppliers, midstream wheel hub manufacturing enterprises, and downstream vehicle manufacturers and after-sales service markets. The upstream is mainly suppliers of raw materials such as aluminum alloy and mechanical equipment, providing key materials for wheel hub manufacturing. The midstream is wheel hub manufacturing enterprises, involving multiple processes such as casting and forging, and producing wheel hubs with different specifications and shapes. The downstream is mainly automobile manufacturers and parts dealers, which ultimately apply the wheel hubs to the vehicle.

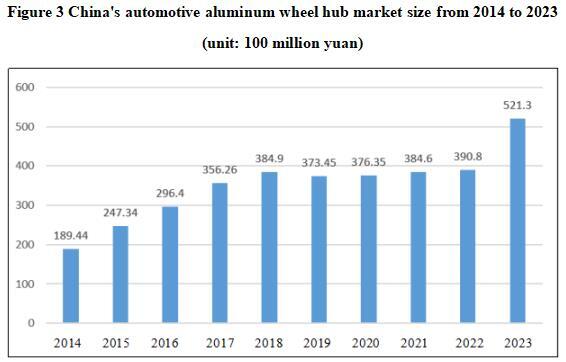

In automotive aluminum wheel hub products, according to their surface treatment processes, it can be divided into coated wheels, polished wheels, electroplated wheels, vacuum electroplated wheels, etc., and each type of wheel hub has its own characteristics and scope of application. According to statistics, the size of China's automotive aluminum wheel hub market reached 52.13 billion yuan in 2023, and the production and demand in the domestic market were 247.48 million and 155.6 million pieces respectively.

There are more than 200 enterprises above designated size in the production of aluminum wheel hubs in China. At the same time as the number of wheel enterprises is expanding, there is a clear cluster ladder distribution of enterprises in the industry. Currently, China has formed two major clusters mainly for vehicle manufacturer supporting and for aftermarket sales. Due to the high requirements of automobile manufacturers for the scale, technology development capabilities, product quality and timeliness of supply of supporting suppliers, the aluminum wheel hub manufacturers that support the vehicle are generally large-scale enterprises with leading production scale, strong technology development capabilities and excellent product quality consistency in the industry. At present, only a small number of aluminum wheel hub manufacturers in China have entered the vehicle supporting market, such as CITIC Dicastal, Wanfeng Auto, Lizhong Wheel, Jinfei Kaida, Liufeng Machinery, etc. These enterprises are larger and stronger, occupying most of the domestic OEM market, and some enterprises export their products to major international OEM market. In contrast, the vast majority of manufacturers mainly supply the domestic and foreign after-sales service markets. However, the domestic after-sales service market is not mature enough, and the demand for wheel hubs is relatively small.

(3) Development trend of automotive wheel hubs

① Lightweight design: with the increasing awareness of environmental protection and energy conservation, automobile manufacturers will also put forward higher requirements for wheel hubs while seeking to reduce the weight of automobiles in order to improve fuel efficiency and reduce emissions. Lightweight design will become the mainstream trend in the market, using lighter and stronger materials, such as aluminum alloy, carbon fiber, etc., to reduce the weight of the vehicle and improve the performance of the vehicle.

② Intelligent wheel hubs: with the rapid development of intelligent automotive technology, wheel hubs will also be gradually intelligent. Intelligent wheel hubs may have functions such as monitoring tire status, transmitting data in real time, automatically adjusting air pressure, providing safety warnings, etc., so as to improve driving safety and driving experience.

③ Increased demand for customization: consumers' demand for personalized automobile appearance increases, and the customized wheel hub market may usher in growth. Automobile manufacturers and wheel hub suppliers may offer more diverse selections of designs and materials to meet the personalized needs of different consumers.

④ Increased demand for electric vehicle wheel hubs: with the rapid growth of the electric vehicle market, the demand for lightweight and low rolling resistance wheel hubs will increase. The wheel hub design of electric vehicles may focus more on reducing rolling resistance and increasing driving range.

⑤ Environmental protection and sustainable development: wheel hub manufacturers may pay more attention to environmental protection and sustainable development, using renewable or recyclable materials for manufacturing to reduce the impact on the environment.

The project relies on the existing industrial foundation in Liaoyuan City to produce aluminum automotive wheel hubs, with broad market prospects.

1.1.3 Technical analysis

The project is planned to cooperate with large domestic enterprises in this field and adopt conventional forging technology. Forging is one of the earliest forming processes for aluminum wheel hubs. Forged aluminum wheel hubs have the advantages of high strength, good corrosion resistance, precise size, and small processing volume. Their weight is generally only equivalent to 1/2 or less of steel wheel hubs of the same size. The grain flow direction of forged aluminum wheel hubs is consistent with the direction of stress, and their strength, toughness and fatigue strength are significantly better than those of cast aluminum wheel hubs. At the same time, the properties are very reproducible, with almost every hub having the same mechanical properties. The typical elongation of forged aluminum wheel hubs is 12%~17%, so they can absorb the vibration and stress of the road well. Cast wheel hubs are typically quite capable of withstanding compressive forces, but are far less capable of bearing impact, shear and tensile loads than forged aluminum wheel hubs. Forged wheel hubs have a higher strength-to-weight ratio.

1.1.4 Advantageous conditions of project construction

(1) Policy conditions

The 14th Five-Year Plan for the National Economic and Social Development of Jilin Province and the Outline of the Long-term Vision Goal for 2035 proposes that by 2025, the local supporting rate of parts in Jilin Province will reach 70%, and the scale of the automotive industry will exceed one trillion yuan.

On May 22, 2024, the General Office of the People's Government of Jilin Province issued the Action Plan for the High-Quality Development of New Energy and Intelligent Connected Vehicle Industry in Jilin Province, proposing that by 2026, the development layout of the province's new energy and intelligent connected vehicle industry will be more optimized, and the industrial scale and competitiveness will rank among the top in China. The production and sales of new energy vehicles in the province will exceed 500000, with the penetration rate of domestic brand new energy vehicles exceeding 40%. The local supporting rate of key parts in new energy has increased significantly, accounting for 70%.

In January 2023, the Jilin Provincial People's Government issued the Opinions of Jilin Provincial People's Government on the Implementation of the "Step up" Project of the Automotive industry Cluster, proposing that by 2025, the strength of the industrial clusters will be further enhanced, the industrial ecology will be comprehensively constructed, and the industrial scale will reach trillions of yuan; a new development pattern will be constructed with the Changchun automobile cluster as the core, and Jilin, Siping, Liaoyuan, Songyuan, Baicheng, Yanbian, Meihekou and other regions as specialized "supporting clusters" to coordinate and interconnect. FAW Group will be built as a world-class enterprise, Changchun will be built as a world-class automobile city, a new energy vehicle enterprise and brand will be introduced, a number of key parts enterprises will be cultivated, a number of innovation platforms will be created, a number of industry-education integration projects will be promoted, a number of key technologies will be broken through, and a number of application scenarios will be built, basically forming a new ecology of the new energy vehicle industry. The new energy vehicle industry chain and supply chain will serve the whole country and have a certain international radiation ability.

In 2020, the Office of the People's Government of Liaoyuan City issued the Implementation Measures for the Flexible Transfer of Industrial Land in Liaoyuan City (Trial), proposing: the supply of industrial land by means of flexible period, lease before transfer, combination of lease and transfer, and long-term lease shall be provided through bidding, auction and listing in accordance with the law; in principle, the flexible transfer period of industrial land shall be 10, 20, 30 and 40 years. Enterprises are allowed to voluntarily choose the land use right transfer period among the above periods. The Implementation Measures has improved the land supply system in Liaoyuan City while reducing the cost of industrial land.

(2) Resource advantages

In recent years, Liaoyuan City has continued to optimize and adjust the energy structure, fully launched the construction of a clean energy heating demonstration city in the north, and carried out 47 clean heating transformation projects such as "coal to gas" and "coal to electricity", which is expected to reduce coal consumption equivalent to 510000 tons of standard coal. In addition, Liaoyuan is rich in wind energy, solar energy, biomass energy and other resources, providing support for the construction of green and low-carbon projects.

(3) Industrial advantages

In recent years, Jilin Province has made every effort to promote the "six returns", break down the barriers of coordination, gather the strength of all parties, integrate industrial resources, continue to enhance the resilience of the industrial chain and supply chain, and the modern industrial system has become increasingly mature. It strives to transform industrial advantages into Jilin's revitalization advantages.

In order to consolidate and expand industrial advantages and strengthen the automotive industry cluster, in recent years, Liaoyuan City has strengthened cooperation with FAW Group, scientifically formulated the Implementation Plan for the Construction of New Energy Vehicle industry Supporting Base in Liaoyuan, compiled the New Energy Vehicle Parts Industry Development Plan for Liaoyuan City (2021-2025), and created two platforms: New Energy Vehicle Industrial Park and Dongliao Mold Industrial Park in the High-tech Zone.

Liaoyuan High-tech Industrial Development Zone, Jilin Province has planned a 4-square-kilometer automotive parts industrial park, focusing on the development of automotive parts and equipment manufacturing related industries.

(4) Talent advantages

Liaoyuan City is rich in human resources, and there are vocational colleges in the urban area, which can train talents according to the needs of enterprises. Liaoyuan City has a good foundation for industrial development, only 115.13 kilometers away from Changchun, a well-known "University City" and "Automobile City", which can meet the various talent needs of enterprises.

(5) Location and transportation advantages

Liaoyuan has obvious geographical advantages, 140 kilometers away from Changchun Longjia International Airport in the north and 240 kilometers away from Shenyang Taoxian International Airport in the south. It is located in the important axis belt of Changchun one-hour economic circle and Shenyang Railway urban agglomeration. Within a radius of 200 kilometers, there are 2 provincial capitals and 8 prefecture-level cities, with a population of nearly 40 million. The urban area has built a transportation network of "three rings, four verticals and six horizontals". The inter-regional highway and railway traffic is developed, No. 303 National Highway and Siping-Meihekou Railway run through the whole territory, and Liaoyuan-Xifeng, Liaoyuan-Changchun Railways, Changchun-Liaoyuan, Yingchengzi-Meihekou, Jilin-Caoshi, Liaoyuan-Xifeng Expressways, and Liaoyuan Civil Airport that will be built soon, constitute a comprehensive transportation system for entering the hinterland of the Northeast, the sea and customs.

1.2 Contents and scale of project construction

1.2.1 Product scale

After the completion of the project, an annual production capacity of 400000 sets of automotive wheel hubs will be formed.

1.2.2 Contents of project construction

The project covers an area of 40000 square meters, with a construction area of 30000 square meters, production workshops, auxiliary workshops, logistics warehouses, product warehouses, machine repair workshops, ancillary rooms, etc. will be mainly built, and production equipment will be purchased.

1.3 Total investment of the project and capital raising

1.3.1 Total investment of the project

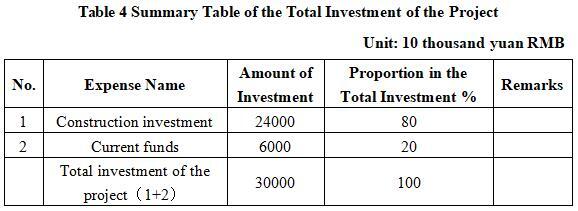

The total investment of the project is 300 million yuan, including the construction investment of 240 million yuan and the current funds of 60 million yuan.

1.3.2 Capital raising

Self-raised by enterprise

1.4 Financial analysis and social evaluation

1.4.1 Main financial indexes

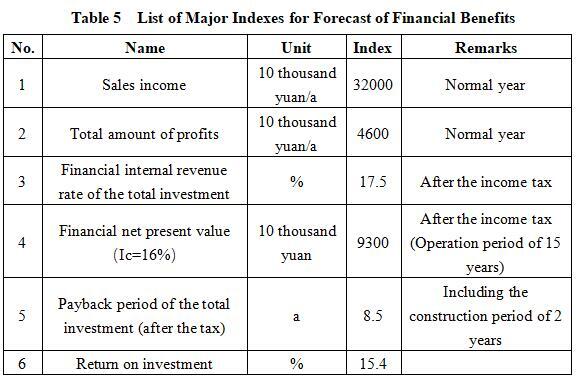

After the project reaches the production capacity, its annual sales income will be 320 million yuan, its profit will be 46 million yuan, its investment payback period will be 8.5 years (after the tax, including the construction period of 2 years) and its investment profit rate will be 15.4%.

Note: “10 thousand yuan” in the table is in RMB.

1.4.2 Social evaluation

Through the construction of the project, it can promote the development of the automotive parts industry in Liaoyuan City, extend the automotive parts industry chain, drive the development of upstream and downstream industries, and form industrial agglomeration; at the same time, it can provide more employment positions for the local area, improve people's living standards, and promote the harmonious development of society.

1.5 Cooperative way

Joint venture, cooperation and other ways can be interviewed

1.6 What to be invested by the foreign party

Funds and other ways can be interviewed

1.7 Construction site of the project

Liaoyuan High-tech Industrial Development Zone, Jilin Province.

1.8 Progress of the project

Attracting foreign investment.

2. Introduction to the Partner

2.1 Basic information

Name: Management Committee of Liaoyuan High-tech Industrial Development Zone, Jilin Province

Address: No. 1633 Caifu Road, Liaoyuan City

2.2 Overview

Liaoyuan High-tech Industrial Development Zone was established in 2001. In 2019, it was approved by the Jilin Provincial People's Government to be established as a provincial-level high-tech industrial development zone, with a planned area of 16.22 square kilometers and a total population of 29000. Located in the axis belt of the two major economic zones of Changchun and Shenyang, it is 100 kilometers away from Changchun in the north, 200 kilometers away from Shenyang in the south and 500 kilometers away from Dalian Port. No. 303 National Highway and Siping-Meihekou, Liaoyuan-Xifeng, Liaoyuan-Changchun Railways run through the whole territory, forming a comprehensive transportation system that extends in all directions with Changchun-Liaoyuan, Yitong-Kaiyuan, Yingchengzi-Meihekou, Jilin-Caoshi Expressways. As the core of Jilin Province's southward opening portal, it plays an important role in the construction of innovation and transformation core area in the central part of Jilin Province.

As the core of scientific and technological innovation, the engine of industrial upgrading, the window for attracting investment, and the leader of economic development, Liaoyuan High-tech Zone actively cultivates new kinetic energy for development, takes the road of characteristic development and differentiated development, promotes innovation and entrepreneurship, improves the quality of supply, and opens a new model of coordinated development of industrial clusters and chain industries. It has been listed as a pilot for regional brand construction of national industrial clusters, a provincial-level demonstration base for mass entrepreneurship and innovation, a national demonstration base for entrepreneurship and innovation of small and micro enterprises, and a demonstration base for new industrialization industries.

In recent years, Liaoyuan High-tech Zone has accurately planned and positioned itself, forming a functional layout of "dual-core drive, one district and four parks", and the large-scale and cluster expansion of "4+1 industry", with 2111 enterprises settled. The textile hosiery industry is unique, supporting the reputation of "China's Cotton Socks Capital" and "China's Famous City of Hosiery", and the production and sales of cotton socks rank first in the country. It has successively become a national-level export hosiery product quality and safety demonstration zone and a national-level foreign trade transformation and upgrading base; the extrusion technology of high-precision aluminum profiles is the world leading. With Qixing Aluminum Industry, Jusheng Light Alloy and Liyuan Precision Manurfacturing as the leaders, the northern high-precision aluminum processing base has been built, and the market share of high-speed train body profiles accounts for nearly 60% in China. Lightweight products have jumped into the high-end market, and it has become an important strategic partner with Fortune 500 companies such as CRRC, Siemens, Alstom, and Bombardier; the pharmaceutical and health industry has obvious advantages. It has 176 drug numbers and is building a pharmaceutical fine chemical park covering an area of 2.62 square kilometers. Under the leadership of many key enterprises such as Boda Pharmaceutical, Boda Weiye, Baikang Pharmaceutical, Yinying Pharmaceutical, etc., the research and development system of anti-tumor drugs, anti-virus drugs, and health care products has become increasingly mature, and it has become the largest production base of chemical raw medicines in Jilin Province; the scale of the supporting industry for new energy vehicles has expanded rapidly; it plans to build a 4 square kilometer new energy vehicle supporting industrial base, forming a new energy vehicle supporting industrial system with Hongtu Lithium-ion Battery Separator, Sinopoly New Energy, Joyson Electronics, Shengyuan New Materials, and Jincheng Heavy Industry as the core, and has been designated as a strategic partner of FAW by the provincial government and signed a strategic cooperation agreement with FAW-FINDREAMS. The modern service industry promotes the integration of industry and city. It will vigorously develop productive and living service industries, actively promote the construction of JD.com, Yunxiang Smart Logistics Industrial Park, Holiday Inn Express Qixing, New Century Hotel, Ouya Shopping Center Phase II and other projects, and water, electricity, gas and other productive factors are fully guaranteed. It will plan Beijiang Commercial Street, revitalize Interlaken Square, renovate Youyi Road Commercial Street, and comprehensively create a characteristic commercial block integrating leisure, entertainment, catering, accommodation, commerce and other formats, as well as eating, drinking, playing and shopping.

2.3 Contact method

Postal code: 136299

Contact person: Song Yang

Tel: +86-437-3292088

Fax: +86-437-3292088

E-mail: jllyjk@163.com

Contact method of the city (prefecture) where the project is located:

Contact unit: Liaoyuan Municipal Bureau of Commerce

Contact person: Ai Jing

Tel: +86-18643787709

E-mail: lyjhjxmc@163.com