Automobile and Parts

Automotive Parts Production Project of Xinlong Plastic of Liaoyuan City

1 Introduction to the Project

1.1 Project background

1.1.1 Product introduction

Plastic components play a pivotal role in automobile manufacturing, with a wide range of applications including interior and exterior trim parts, engine components, electrical components, tires, automotive lamps and lanterns, automotive air conditioning systems, sound insulation materials, seals, etc. These plastic parts are not only lightweight, but also have excellent comprehensive physical and chemical properties, including insulation, corrosion resistance, aging resistance, as well as good wear resistance, scrub resistance, excellent decorative effect, and processing plasticity. Common automotive plastic products include interior and exterior trim parts, engine components, electrical components, tires, automotive lamps and lanterns, automotive air conditioning systems, sound insulation materials, seals, etc.

The construction site of the project is located in Longshan District, Liaoyuan City, and it is planned to use the existing plant and purchase new production equipment to produce composite automotive parts.

1.1.2 Market prospect

(1) Global automotive plastics market situation

As the foundation of the automotive industry, automotive parts are a necessary factor to support the sustainable and healthy development of the automotive industry. With the continuous advancement of economic globalization, automotive parts companies around the world actively join the process of industrial globalization, so that the automotive industry chain of various countries is integrated.

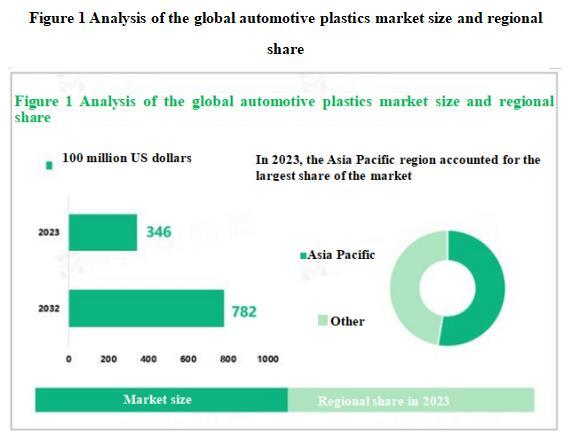

In 2023, the global automotive plastics market size was 34.6 billion US dollars, and its size is expected to reach 78.2 billion US dollars by 2032.

At present, there are many suppliers of automotive plastic parts in the world, including Robert Bosch, ZF Friedrichshafen, Magna International, DENSO, Continental and so on.

(2) Overview of China's automotive parts market

The automotive industry is the pillar industry of China's national economy, which has the characteristics of large market potential, high correlation, strong consumption drive, obvious scale benefits, and intensive capital and technology. The automotive parts industry is the foundation of the development of the automotive industry, an important condition to support the sustainable and steady development of the automotive industry, and an important link in the automotive industry chain. Automotive parts include various parts and components of motor vehicles and their bodies, and an automobile is usually composed of tens of thousands of parts.

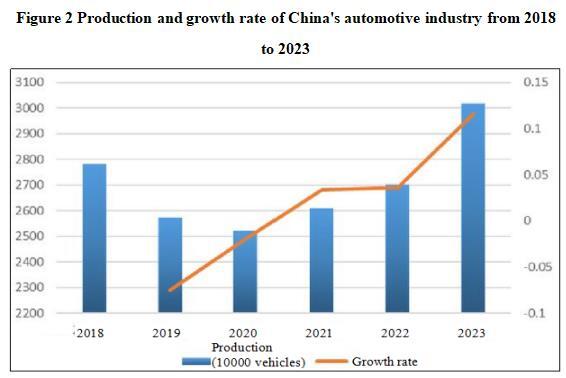

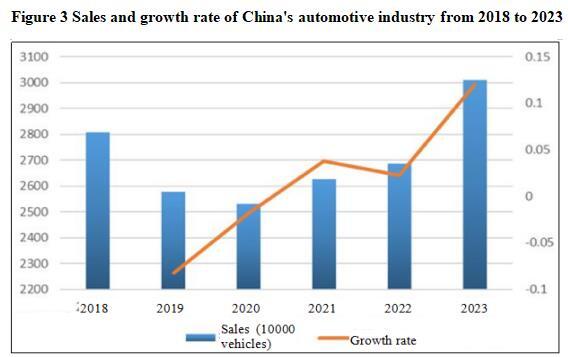

In 2023, the total production and sales of automobiles in China were 30.161 million and 30.094 million respectively. On the one hand, this shows that China's automobile market space is huge, on the other hand, it also shows that people's quality of life is improving day by day, and the demand for automobiles is continuously increasing. The China Association of Automobile Manufacturers stated that in 2024, China would continue to adhere to the general principle of seeking progress while maintaining stability, vigorously boost market confidence, implement the strategy of expanding domestic demand, actively promote the overall improvement of economic operation, and achieve effective improvement in quality and reasonable growth in quantity. With the implementation of supporting policies and measures related to the automotive industry, the vitality of market entities and consumption will be further stimulated, and confidence in the improvement of the economy throughout the year will be filled.

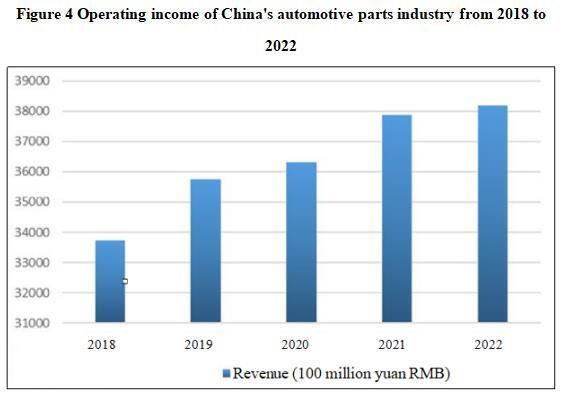

Automotive parts are undoubtedly the cornerstone of the development of the automotive industry, and their importance is self-evident. As a core component of the automotive industry, the output value of automotive parts occupies a pivotal position in the output value of the vehicle, usually accounting for 50% to 70% of the share. In 2022, the operating income of automotive parts reached 3.8195 trillion yuan, accounting for 46.81% of the income of the automobile manufacturing industry. It can be seen from this that with the strong support at the policy level, the consumption confidence at the lower end is gradually recovering, and the automotive parts industry in China still has a good potential market and great development space.

(3) Development trend of China's automotive parts industry

① Under the trend of automotive lightweight, the plastic parts industry is developing rapidly

At present, modified plastics have significant advantages such as low cost and high performance, and they are the materials second only to metals in terms of consumption in the automotive materials. "Replacing steel with plastics" has become one of the important ways to achieve automotive lightweight. Replacing metal materials with modified plastics in automotive components and load-bearing structures can significantly reduce the quality of workpieces. Moreover, modified plastics are intermediate products in the petrochemical industry chain, mainly processed from five general-purpose plastics and five engineering plastics as the plastic matrix. They have characteristics such as flame retardancy, impact resistance, high toughness and easy processability, and are therefore widely used in automotive parts. Common modified plastics include modified PP and modified PA, among which modified PP accounts for 46% of the modified plastics used in domestic automobiles.

② The trend of domestic substitution of automotive parts is obvious, promoting the development of domestic small and medium-sized enterprises

In recent years, the localization trend of automotive parts in China's automotive industry has been continuously strengthened. This trend is mainly influenced by national policy support, cost advantages and the improvement of technological strength.

First of all, domestic automotive parts enterprises meet market demand by continuously improving technological strength and production capacity. Compared with the traditional automotive industry power, there is still a large gap in the design, research and development and production capacity of China's automotive parts industry. However, in recent years, with the rapid development of China's automobile market, domestic parts enterprises have increased investment in technology research and development and innovation, and continuously improved product quality and performance. At the same time, many domestic parts companies have improved their production capacity and manufacturing level through cooperation with internationally renowned enterprises and the introduction of high-end equipment, and have gradually won the recognition of many vehicle manufacturers.

Secondly, localization can reduce costs and improve production efficiency. Traditionally, Chinese automobile enterprises have relied heavily on imported components, which has led to relatively high production costs. However, by adopting domestic components, enterprises can effectively reduce procurement costs, and at the same time reduce the links in the supply chain, breaking the dependence on imports. What's more, localization can provide faster response and flexibility to meet changes in market demand.

③ Driven by multiple factors such as energy conservation and emission reduction

In order to meet increasingly stringent environmental regulations and improve fuel efficiency, automobile manufacturers are actively adopting lightweight materials, which will promote the demand for automotive plastic parts to further increase, the future development potential of China's automotive plastic parts industry is still huge, driven by environmental protection, lightweight, intelligence, electrification and other factors, automotive plastic parts will continue to make important contributions to the development of China's automobile manufacturing industry, towards a greener, intelligent and sustainable direction.

In 2021, the "carbon peaking" related action plan was introduced, and in 2022, the "14th Five-Year Plan" energy plans in various regions were implemented one after another. With the accelerated implementation of relevant carbon reduction requirements, energy conservation and emission reduction have become the top priority for the development of the automotive industry. In this context, China's automotive plastic parts industry ushered in a golden period of development. In 2022, China's demand for automotive plastic parts reached 4.929 million tons, the average sales price reached 19900 yuan/ton, and the market size reached 98.09 billion yuan, of which interior trim parts accounting for 76.4%, exterior trim parts accounting for about 14.7% and structural parts accounting for about 8.9%. In the future, as the trend of automotive plasticization takes shape, the application and promotion of automotive plastic parts are expected to accelerate, and the whole industry will continue to maintain a high-speed development trend, with a broad market prospect.

1.1.3 Technical analysis

The project adopts multi-component injection molding technology, which combines different plastic materials or colors in a single molding. Production can be completed in a single process without the need for other assembly or post-processing steps outside the machine. Multi-component injection molding is a fully automated process with a high degree of flexibility, especially suitable for mass injection molding of plastic shells.

1.1.4 Advantageous conditions of project construction

(1) Policy advantages

In recent years, the state has successively promulgated the Automotive industry Development Policy, the Several Opinions of the State Council on Accelerating the Revitalization of the Equipment Manufacturing Industry, the Automotive industry Adjustment and Revitalization Plan, the Opinions on Promoting the Sustainable and Healthy Development of China's Automotive Product Exports and other industrial policies, pointing out that it is necessary to vigorously promote the structural adjustment and industrial upgrading of the automotive plastic parts industry; to improve international competitiveness, promote the sustained, healthy and stable development of China's automobile and parts exports, provide a favorable policy environment for China's automotive plastic parts industry, and effectively promote the sustainable and healthy development of the industry. In addition, in the context of China's rapid economic growth and substantial increase in residents' income, automobile consumption continues to heat up, effectively driving the rapid growth of China's automotive industry. Due to the huge demand for components in the automobile market, the continuous growth of the automotive industry has directly driven the rapid development of the automotive plastic parts industry.

In February 2023, the Jilin Provincial People's Government issued the Opinions of Jilin Provincial People's Government on the Implementation of the "Step up" Project of the Automotive industry Cluster, proposing that by 2025, the strength of the industrial clusters will be further enhanced, the industrial ecology will be comprehensively constructed, and the industrial scale will reach trillions of yuan; a new development pattern will be constructed with the Changchun automobile cluster as the core, and Jilin, Siping, Liaoyuan, Songyuan, Baicheng, Yanbian, Meihekou and other regions as specialized "supporting clusters" to coordinate and interconnect. FAW Group will be built as a world-class enterprise, Changchun will be built as a world-class automobile city, a new energy vehicle enterprise and brand will be introduced, a number of key parts enterprises will be cultivated, a number of innovation platforms will be created, a number of industry-education integration projects will be promoted, a number of key technologies will be broken through, and a number of application scenarios will be built, basically forming a new ecology of the new energy vehicle industry. The new energy vehicle industry chain and supply chain will serve the whole country and have a certain international radiation ability.

(2) Industrial advantages

In recent years, Jilin Province has made every effort to promote the "six returns", break down the barriers of coordination, gather the strength of all parties, integrate industrial resources, continue to enhance the resilience of the industrial chain and supply chain, and the modern industrial system has become increasingly mature. It strives to transform industrial advantages into Jilin's revitalization advantages.

Liaoyuan has a strong industrial foundation and strong development momentum. Liaoyuan is an important industrial city in Northeast China, and was once known as "Little Shanghai in Northeast China" because of its developed light industry. It has the industrial foundation of the old industrial base in Northeast China, and has the inherent advantage of undertaking various industrial transfers and grafting. At present, it has formed a continuous and alternative industrial structure, with equipment manufacturing and deep processing of agricultural products as the two leading industries, and high-precision aluminum processing, textile and sock industry, medicine and health, egg processing, and new energy as the five characteristic advantageous industries. The development potential is enormous and the momentum is strong.

(3) Location and transportation advantages

Liaoyuan has obvious geographical advantages, 140 kilometers away from Changchun Longjia International Airport in the north and 240 kilometers away from Shenyang Taoxian International Airport in the south. It is located in the important axis belt of Changchun one-hour economic circle and Shenyang Railway urban agglomeration. Within a radius of 200 kilometers, there are 2 provincial capitals and 8 prefecture-level cities, with a population of nearly 40 million. The urban area has built a transportation network of "three rings, four verticals and six horizontals". The inter-regional highway and railway traffic is developed, No. 303 National Highway and Siping-Meihekou Railway run through the whole territory, and Liaoyuan-Xifeng, Liaoyuan-Changchun Railways, Changchun-Liaoyuan, Yingchengzi-Meihekou, Jilin-Caoshi, Liaoyuan-Xifeng Expressways, and Liaoyuan Civil Airport that will be built soon, constitute a comprehensive transportation system for entering the hinterland of the Northeast, the sea and customs.

(4) Talent advantages

The Liaoyuan Municipal Party Committee and Municipal Government have established a "green channel" for the introduction of master's and doctoral talents, and since 2022, 713 master's and doctoral talents have been recruited at one time. At the same time, focusing on the shortcomings of industrial development, organizing and carrying out technical docking activities such as the Sunday Engineer Part-time Plan, 63 enterprises and institutions in the city cooperated with 23 universities and institutes such as Jilin University, and "targeted" the introduction of 92 high-level talents.

Liaoyuan City actively builds a platform carrier and continues to carry out the "five fronts" activities. Since 2021, a total of 144 college students have been selected and dispatched to serve in key areas such as economic projects, reform and development, urban construction, grassroots governance, and rural revitalization. At the same time, it organizes and carries out campus recruitment, adopts the method of " recruiting for public institutions and serving enterprises", and selects 26 professional master's and doctoral talents urgently needed by enterprises to serve in enterprises, so as to achieve a "win-win" situation of career development and talent training.

1.2 Contents and scale of project construction

The project utilizes the existing plant, purchases new production equipment, and produces composite automotive parts.

1.3 Total investment of the project and capital raising

1.3.1 Total investment of the project

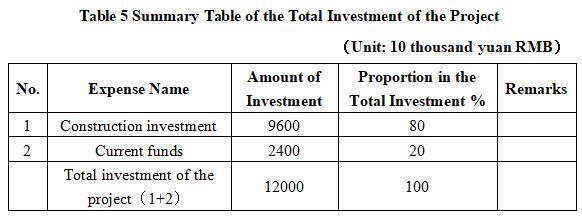

The total investment of the project is 120 million yuan, including the construction investment of 96 million yuan and the current funds of 24 million yuan.

1.3.2 Capital raising

Self-raised by enterprise

1.4 Financial analysis and social evaluation

1.4.1 Main financial indexes

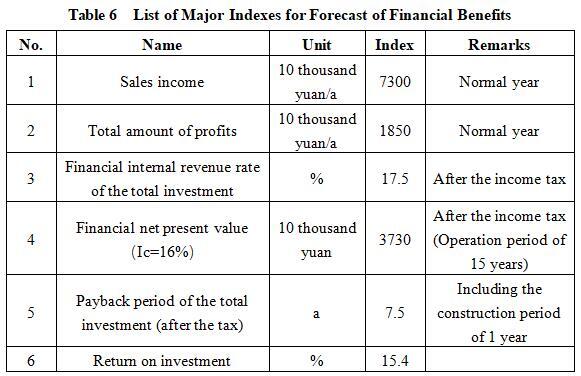

After the project reaches the production capacity, its annual sales income will be 75 million yuan, its profit will be 18.5 million yuan, its investment payback period will be 7.5 years (after the tax, including the construction period of 1 year) and its investment profit rate will be 15.4%.

Note: “10 thousand yuan” in the table is in RMB.

1.4.2 Social evaluation

Through the construction of the project, it can promote the development of the automotive parts industry in Liaoyuan City, extend the automotive parts industry chain, drive the development of upstream and downstream industries, and form industrial agglomeration; at the same time, it can provide more employment positions for the local area, improve people's living standards, and promote the harmonious development of society.

1.5 Cooperative way

Joint venture, cooperation and other ways can be interviewed

1.6 What to be invested by the foreign party

Funds and other ways can be interviewed

1.7 Construction site of the project

Longshan District, Liaoyuan City, Jilin Province.

1.8 Progress of the project

Attracting foreign investment.

2. Introduction to the Partner

2.1 Basic information

Liaoyuan Xinlong Plastic Co., Ltd.

Address: Group 2, Shoushan Town, Longshan District, Liaoyuan City, Jilin Province.

2.2 Overview

Liaoyuan Xinlong Plastic Co., Ltd. is located in Longshan Industrial Development Zone, Liaoyuan City, covering an area of 15000 square meters, and has developed into a technology-based enterprise specializing in the research and development and production of automotive injection molding supporting products through continuous optimization and innovation. It has a team of engineering and technical personnel and production line backbone personnel with more than 30-year production and operation experience, as well as a modern office building (1500 square meters) and a standard workshop (3000 square meters). It has passed the new version of IATF16949 international quality system certification, and has been recognized as a "technology small giant" enterprise by Jilin Provincial Department of Science and Technology, as a pilot enterprise of "industry-education integration " by Jilin Provincial Development and Reform Commission, as a provincial "specialized, refined, distinctive and innovative" enterprise by Jilin Provincial Department of Industry and Information Technology, and the title of "excellent Party organization with strong Party building and strong enterprise" by the Organization Department of Provincial Party Committee.

In recent years, through continuous scientific and technological innovation and research and development activities, it has successfully obtained an invention patent and several utility model patents. The company focuses on the production of automotive plastic parts and plastic products. It is an enterprise specialized in the production of automotive supporting products such as automobiles, trucks, new energy vehicles and interior trim injection molded parts. It is an official supporting route manufacturer for many companies such as FAW Jiefang Group Company, FAW Fawer, FAW Fudi Group Company, FAW-Volkswagen Lear Shengyuan Company, Yantai Zhenghai Group, Quark Precision Group, etc. There are more than 100 kinds of automotive supporting injection molded parts products, with an annual production capacity of 1500 tons. The supporting vehicle models include the Volkswagen series, Audi series, FAW Car series, Jiefang truck series, new energy vehicle series, etc. The vehicle models involved include Audi, Magotan, Bora, Jetta, Toyota, Hongqi, Great Wall, Hyundai, Geely, Changan, new energy vehicles, etc. Every month, the company produces and supplies according to the supply plan proposed by automobile manufacturers. The market is stable, and the automotive supporting injection molded parts products are constantly moving towards domestic and foreign markets, with a promising market development prospect.

2.3 Contact method

Postal code: 136200

Contact person: Bi Chengye

Tel: +86-437-3166166 +86-13258791949

Contact method of the city (prefecture) where the project is located:

Contact unit: Liaoyuan Municipal Bureau of Commerce

Contact person: Ai Jing

Tel: +86-18643787709

E-mail: lyjhjxmc@163.com