Processing of Agricultural Products and Food

Straw Comprehensive Utilization Industrial Park Project of Liaoyuan City

1 Introduction to the Project

1.1 Project background

1.1.1 Product introduction

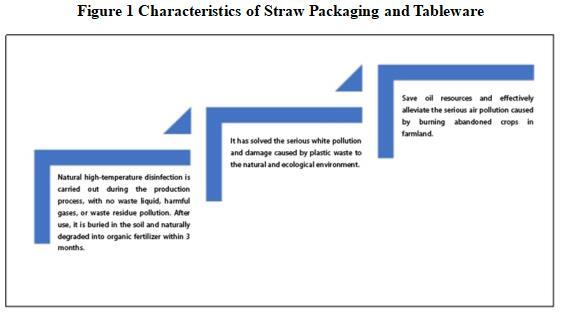

Comprehensive utilization of straw refers to the conversion of crop straw into useful resources or energy through various means in order to solve energy crises, reduce environmental pollution, and protect the ecological environment. Its main utilization methods include returning straw to the field, returning it to the abdomen, cultivating edible fungi, producing biogas, using it as industrial raw materials, biomass power generation, etc.

The project relies on the existing industrial foundation in Liaoyuan City and builds a straw comprehensive utilization industrial park in Dongfeng County. It uses straw to produce packaging and tableware, which can be completely degraded compared to traditional plastic packaging and tableware, without generating garbage pollution and is more environmentally friendly.

1.1.2 Market prospect

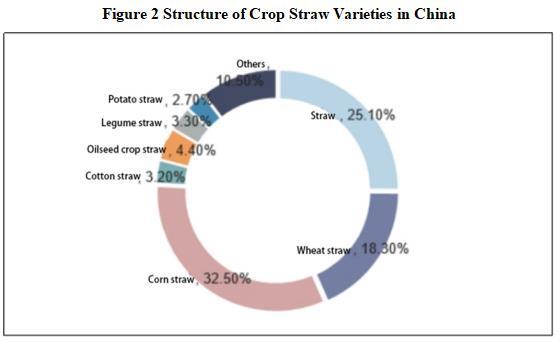

Straw is the largest by-product of China’s grain crops. Straw is the general term for the stems, leaves, and ears of mature crops. It usually refers to the remaining portion of wheat, rice, corn, potatoes, rapeseed, cotton, sugarcane, and other crops (usually coarse grains) after harvesting the seeds. The straw production of major crops such as corn, rice, wheat, rapeseed, soybeans, and cotton in China is 865 million tons, and the collectable amount is 731 million tons.

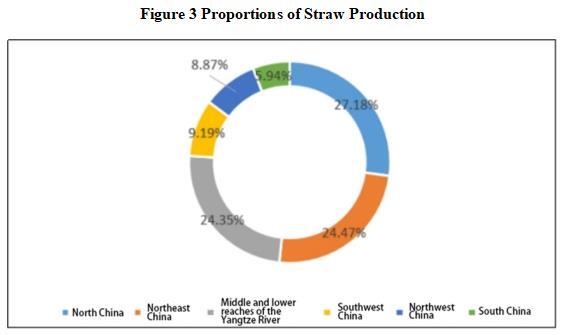

In terms of straw production, the regions from highest to lowest are North China, Northeast China, the middle and lower reaches of the Yangtze River, Southwest China, Northwest China, and South China, accounting for 27.18%, 24.47%, 24.35%, 9.19%, 8.87%, and 5.95% of the total straw production in China, respectively.

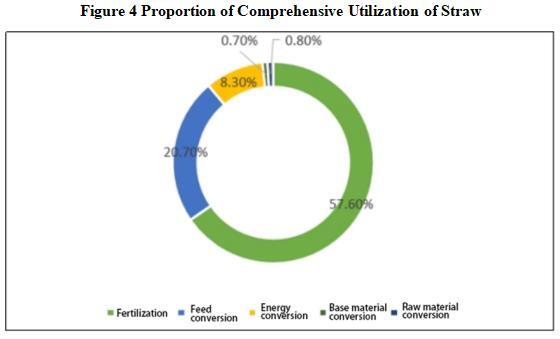

In recent years, the agricultural and rural departments have attached great importance to the comprehensive utilization of straw, adhering to the priority of agricultural use, multiple measures, and industrial orientation. They have deeply implemented the action of straw comprehensive utilization, continuously improved the efficiency of straw comprehensive utilization nationwide, and promoted the formation of a diversified utilization pattern that focuses on fertilizer and feed according to local conditions, while taking into account energy, base materials, and raw materials. By now, the comprehensive utilization rate has reached 88.1%, with utilization rates of 57.6%, 20.7%, 8.3%, 0.7%, and 0.8% for fertilizer, feed, energy, base material, and raw material, respectively.

At present, there are a total of 249 patents related to plant fiber packaging materials in China, including 100 for plant fiber tableware. If plant fiber materials such as straw, corn stover, and sugarcane bagasse are thoroughly mixed with polypropylene, and photosensitizers are added, fast food boxes, vegetable dishes, etc. can be produced through molding processes. By replacing the molds, environmentally friendly products such as supermarket trays, tofu boxes, ice cream cups, fruit and vegetable packaging boxes, egg trays, and seedling trays can be produced. The relevant technology is relatively mature and has achieved industrialization.

There are also many pure plant fiber food utensils and packaging products available in the mid to high end consumer market, such as disposable fully biodegradable pulp molded meal boxes made from plant fibers extracted from wheat straw and sugarcane bagasse. They can be composted and fully degraded in 40-90 days without chemical wastewater or residue, but the price is relatively high and mainly targeted at foreign markets.

The main domestic production enterprises and consumer markets are concentrated in the Pearl River Delta and Yangtze River Delta regions. With the increasingly prominent environmental issues, the continuous improvement of economic development and people’s living standards, as well as the enhancement of environmental awareness, the market for plant fiber tableware has been steadily growing year by year.

In the highly competitive packaging industry, industry leaders frequently target the “plant fiber packaging” market strategically, and the significance of this is self-evident - plant fiber packaging has become a key breakthrough for industry enterprises seeking better development. The reason why plant fiber packaging has risen to prominence in the packaging industry is due to the enthusiastic pursuit of end users. According to incomplete statistics, in the past two years, there have been over 50 well-known terminal brands using plant fiber packaging.

At present, the proportion of plant fiber packaging industry is very small, and the industry output value is only in the billions. More than 140 million tons of plastic are synthesized from petroleum every year worldwide, and China’s production is about 8 million tons. As long as 1% of the products are replaced with environment-friendly plant fiber materials, a huge industry can be formed.

Overall, the project relies on the existing infrastructure in Liaoyuan City and utilizes straw to produce packaging and tableware, with a broad market prospect.

1.1.3 Technical analysis

The project uses mechanical methods to produce fibers without changing the molecular structure of lignin, allowing the fibers to tear, crush, pulverize, and swell, and have the conditions to form pulp. By utilizing the characteristic of lignin transforming from a hard and brittle glassy state to a softer rubbery state at temperatures of 80-130℃, and the weakening of the transverse consolidation force between fibers, the lignin morphology in the straw undergoes some changes, and most of the lignin remains in its original structure in the fibers. The process of molding products using molds through vacuum adsorption. With microcrystalline expanded straw fiber used as the main raw material without adding any harmful chemical additives or whitening agents, the finished product is produced through processes such as room temperature vacuum dehydration molding, cold press dehydration, hot press shaping, demolding, edge cutting, inspection, disinfection, and packaging.

This method is different from chemical pulping methods, as it does not require steaming, does not produce heavily polluted wastewater, and the fiber yield is much higher than that of chemical pulping, reaching up to 85%.

1.1.4 Advantageous conditions of project construction

(1) Policy conditions

The 14th Five-Year Plan for the Development of Circular Economy clearly states that by 2025, China’s resource utilization efficiency will have been significantly improved, the proportion of renewable resources replacing primary resources will have been further increased, and the supporting and guaranteeing role of circular economy in resource security will have been further highlighted. The comprehensive utilization rate of crop straw remains above 86%.

The National Development and Reform Commission and the Ministry of Ecology and Environment have issued the Opinions on Further Strengthening the Control of Plastic Pollution. Compared with the Plastic Restriction Order issued by the State Council in 2007, the new version of the Plastic Restriction Order clearly proposes to promote the use of bio based products such as straw coated meal boxes and biodegradable plastic bags that meet performance and food safety requirements in the field of food delivery.

The Ministry of Agriculture and Rural Affairs, the State Administration for Market Regulation and other six ministries jointly issued the Three-Year Action Plan for Accelerating the Innovative Development of Non Grain Biomass Materials (such as bulk crop straw and residues), proposing to cultivate high-quality enterprises, guide petrochemical and chemical enterprises to leverage their industrial advantages, carry out innovation and application demonstrations in the bio based material industry chain and supply chain, cultivate a group of backbone enterprises that connect the entire industry chain path from crop straw disposal and utilization to downstream products, focus on the cultivation of specialized and innovative “little giants” and single champion enterprises in sub-sectors such as industrial strain breeding and enzyme protein component preparation, and form a pattern of integrated development of large, medium and small enterprises; To optimize regional layout, actively serve the national regional development strategy, focus on promoting the aggregation of innovative resources and elements of bio-based materials to the main production areas of grain, cotton, oil, and sugar crops, create distributed non grain biomass saccharification bases, form a highland of technological innovation, product innovation, and market innovation with regional advantages, support the construction of national new industrialization industrial demonstration bases in the field of bio based materials in eligible industrial agglomeration areas, promote the transformation and upgrading of industries from agglomeration to clusters, and improve scale efficiency and influence.

Since the release of the Three-Year Action Plan for Comprehensive Utilization of Straw in Jilin Province, Jilin Province has been focusing on the raw material utilization of straw, adhering to a market-oriented approach, focusing on high-value utilization of straw, actively promoting new building materials, straw pulp and paper making, straw carbon based fertilizer utilization, developing straw packaging materials, straw tableware and other products, exploring new ways of utilizing straw cellulose ethanol, straw sugar production, straw chemical alcohol, straw butanol and other materials, and comprehensively promoting the construction of straw industrial raw material utilization projects.

The People’s Government of Liaoyuan City has issued the Implementation Opinions on the Comprehensive Rectification and Resource Utilization of Straw of Liaoyuan City, proposing to focus on developing high-end utilization industries with obvious economic benefits and advanced technological processes. Key support will be given to enterprises with high straw utilization rates to ensure stable supply of straw.

The Implementation Plan for the Comprehensive Utilization Project of Crop Straw in Dongfeng County in 2024 proposes to focus on the “raw materials”, “energy”, and “feed” utilization of straw, combine "industrial and agricultural use", promote the comprehensive utilization of straw throughout the county, and make every effort to achieve a comprehensive utilization rate of straw of over 90% within the county. And provide subsidies for straw raw material utilization, energy utilization, feed utilization operations, and straw comprehensive utilization exhibition bases.

(2) Resource advantages

Liaoyuan City is an important grain production base in Jilin Province, and both Dongfeng County and Dongliao County are national commodity grain base counties. The total cultivated land area in the city is 3.63 million mu, of which one-third is sloping land, one-third is flat land, and one-third is low-lying land. The per capita cultivated land for farmers is 5.5 mu. The grain production has remained stable at over 4 billion kilograms throughout the year. In 2023, the city’s straw production will be 1.518 million tons, with a collectable amount of 1.351 million tons and sufficient raw materials.

(3) Industrial advantages

Since 2021, Dongfeng County and Dongliao County have been rated as key counties for comprehensive utilization of straw in China. Every year, they strive to support funds and coordinate with policies such as the Northeast Black Soil Protection Project and conservation tillage to promote the development of comprehensive utilization of straw, laying a solid foundation for the development of straw comprehensive utilization industry projects in Liaoyuan City.

(4) Talent advantages

Liaoyuan City has abundant human resources, and there are vocational colleges in the urban area that can train talents according to the needs of enterprises. Liaoyuan City, with a good industrial development foundation, is only 115.13 kilometers away from Changchun, the nationally renowned “University City” and “Automobile City”, which can meet the various talent needs of enterprises.

At the same time, Liaoyuan City encourages enterprises to jointly establish expert studios, research and development centers, and internship and employment bases for college students with universities and institutions that have signed contracts for cooperation. It also organizes targeted recruitment of professional talents in public institutions, establishes “science and technology innovation teams, science and technology expert workstations (rooms)”, and flexibly introduces talents from outside the country.

(5) Location and transportation advantages

Liaoyuan has obvious location advantages, located 140 kilometers north of Changchun Longjia International Airport and 240 kilometers south of Shenyang Taoxian International Airport. It is situated on an important axis of Changchun’s one hour economic circle and the Shenyang-Tieling urban agglomeration. Within a radius of 200 kilometers, there are 2 provincial capitals and 8 prefecture level cities, with a population of nearly 40 million. The urban area has built a transportation network of “three ring roads, four vertical roads, and six horizontal roads”. Regional highways and railway transportation are well-developed, with No. 303 National Highway and Siping-Meihekou Railway running through the entire area. The Liaoxi and Liaochang railways, as well as the Changliao, Yingmei, Jicao, Liaoyuan-Xifeng expressways and the upcoming Liaoyuan Civil Airport, form a comprehensive transportation system for entering the hinterland of Northeast China and entering the sea.

1.2 Contents and scale of project construction

The project covers an area of 56000 square meters with a building area of 44476.32 square meters. It mainly includes the construction of a research and development center, a material preparation area canopy, a straw raw material storage canopy, and a production plant.

1.3 Total investment of the project and capital raising

1.3.1 Total investment of the project

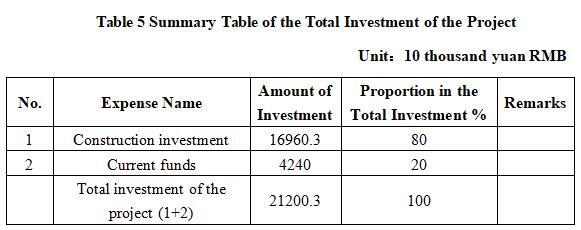

The total investment of the project is 212.003 million yuan, including the construction investment of 169.603 million yuan and current funds of 42.4 million yuan.

1.3.2 Capital raising

Self-financing by the enterprise

1.4 Financial analysis and social evaluation

1.4.1 Main financial indexes

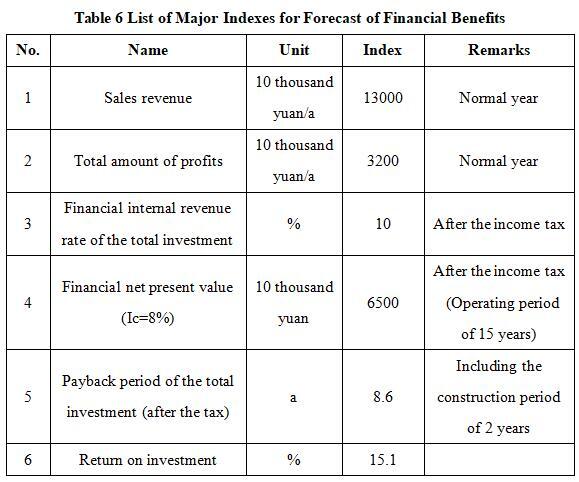

After the project reaches the production capacity, its annual sales revenue will be 130 million yuan, its profit will be 32 million yuan, its investment payback period will be 8.6 years (after the tax, including the construction period of 2 years) and its return on investment will be 15.1%.

Note: “10 thousand yuan” in the table is in RMB.

1.4.2 Social evaluation

After the completion of the project, the collection of straw will be organically connected with straw resource utilization, strengthening the chain of agricultural circular economy, increasing farmers’ income, and promoting the sustainability of agricultural development; at the same time, it can drive local employment and play a good role in promoting local social development.

1.5 Cooperative way

Joint venture or cooperation, and other methods can be discussed face-to-face.

1.6 What to be invested by the foreign party

Funds, and other methods can be discussed face-to-face.

1.7 Construction site of the project

Dongfeng County, Liaoyuan City, Jilin Province

1.8 Progress of the project

It is attracting foreign investment.

2. Introduction to the Partner

2.1 Basic information

Name: Dongfeng Agriculture and Animal Husbandry Investment Development (Group) Co., Ltd.

Address: 226 Dongfeng Road, Donfeng Town, Dongfeng County, Liaoyuan City

2.2 Overview

Dongfeng Agriculture and Animal Husbandry Investment Development (Group) Co., Ltd. is a state-owned sole proprietorship directly under the Dongfeng Government. It was established on March 1, 2022 and is mainly engaged in commercial service industry.

It focuses on investment and financing, as well as the development of modern agriculture and animal husbandry industries. It mainly provides services around the rural revitalization strategy, the transformation of old and new driving forces, and the high-quality development of agriculture and animal husbandry. Relying on the location advantages, resource endowment, and industrial foundation of Dongfeng County’s agriculture and animal husbandry industry, it further promotes the deep integration of “planting, breeding, and sales”, “industry-university-research application”, and “agricultural food culture and tourism”, and comprehensively supports the high-quality, high-strength, and efficient development of Dongfeng County’s modern agriculture and animal husbandry industry.

2.3 Contact method

Postal code: 136300

Contact person: Ma Shuai

Tel: +86-13694085352

E-mail: dfnfjt2022@163.com

Contact method of the city (prefecture) where the project is located:

Contact unit: Liaoyuan Bureau of Commerce

Contact person: Ai Jing

Tel: +86-18643787709

E-mail:: lyjhjxmc@163.com