Sci-Tech Achievement Commercialization

Commercial Vehicle Hydraulic Retarder Sci-Tech Achievement Commercialization Project

1. Introduction to the Project

1.1 Introduction to technical achievements

A hydraulic retarder, also known as a hydraulic buffer, hydraulic deceleration device, engine retarder, etc., is a type of car retarder that reduces the vehicle’s driving speed through a hydraulic device. The function of the hydraulic buffer is to reduce the driving speed of the vehicle and prevent mechanical damages caused by hard collisions.

The commercial vehicle hydraulic retarder technology transformed in this project mainly targets the industry pain points of relying on foreign imports for core components such as solenoid valves and electronic control systems in existing domestic hydraulic retarder products, as well as high manufacturing costs and low production efficiency of high-precision stator/rotor manufacturing processes. It has developed some core technologies such as integrated design and optimization of “electromechanical gas-liquid”, integration of RCU controllers and electromagnetic valve bodies, and high-precision melt casting process for stator/rotor.

1.2 Technical analysis and advantages

1.2.1 Core technical analysis

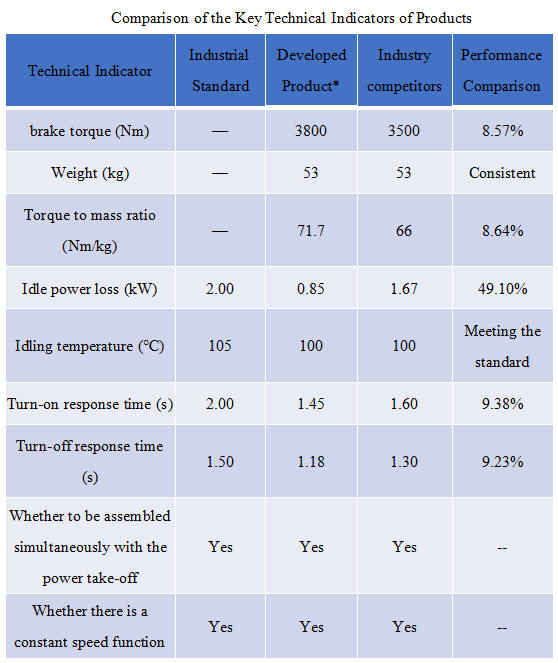

1. Through the “mechanical, electrical, pneumatic, and hydraulic” integrated innovative design and optimization of, the optimization of pneumatic control system and multi-objective optimization of impeller structure based on performance requirements have been achieved, which can more accurately predict dynamic braking torque performance. By simulating and predicting thermal balance through thermal management, theoretical support and design guidance is provided for the design of heat dissipation systems, reducing control losses by 49.1% and improving torque to mass ratio by 8.64%.

2. It has developed a high-precision, fast response, and highly integrated intelligent control system for hydraulic retarders. The self-developed high-speed switch solenoid valve group with digital control has improved control accuracy by 5% and reduced response time by 9%; the electromagnetic valve group adopts a redundant design with two inputs and two outputs, which improves reliability; the RCU, solenoid valve group, and pressure sensor are highly integrated, reducing the cost by 50%; through independent research and development, it has broken the technological monopoly and ensured the security of the supply chain.

3. In response to manufacturing difficulties such as high positioning requirements, hole spacing, coaxiality, and smoothness of cast iron shells, a rough turning stress relief annealing process is adopted to eliminate internal stresses in the blank; it has invented high-precision, deformation resistant, and high rigidity adaptive fixtures, which achieve high clamping accuracy, stable clamping, and non-deformation of components after clamping, ensuring the requirements of high-precision machining. The stator/rotor casting process adopts a unique automatic block extraction mode, which improves the accuracy, increases the production efficiency by 50%, and reduces production costs by 70%.

1.2.2 Technological innovation and advantages

By now, the team has formed a positive product research and development system and the manufacturing, assembly, and testing capabilities of all components. The two major indicators of product cost and reliability are controllable, and the pilot and industrialization preliminary work has been completed, which can completely replace imported products.

1.3 Main products and applications of technical achievements

The hydraulic retarder is suitable for vehicles that frequently use brakes, such as tractors, trucks, dump trucks, buses, and various engineering vehicles, especially for vehicles in mountainous areas and vehicles with long slopes, as well as various dangerous goods transport vehicles with mandatory requirements for transportation safety and vehicle auxiliary braking.

1.4 Stage of technological achievements

The technical achievements of the project are in the industrialization stage.

1.5 Technical team

After years of collaborative work and scientific research practice, the technical team has formed an academic team with the project leaders as academic leaders, middle-aged and young teachers and doctoral students as the backbone in a relatively reasonable educational and professional title structure. In the past five years, it has undertaken 7 national, provincial, and ministerial level projects, as well as 6 enterprise level projects. It has received a total of 17.5378 million yuan in research funding and published 52 papers, including 22 indexed by SCI and 19 indexed by EI; 39 authorized invention patents and 5 software copyrights; It has participated in editing 3 textbooks and revising 1 textbook; in 2019, it received two provincial-level scientific and technological awards, namely, the Second Prize of China Machinery Industry Science and Technology Progress Award (ranking 4th) and the First Prize of China Automation Society Science and Technology Invention Award (ranking 3rd).

2. Market Potential Analysis

The hydraulic retarder of commercial vehicles is an auxiliary braking device composed of electromechanical, pneumatic, and hydraulic components, which is equipped to improve vehicle driving safety. This device can undertake about 70% or more of the braking tasks of commercial vehicles. Especially during downhill driving, it can significantly reduce the use of the main braking device, effectively avoid brake overheating, reduce the occurrence of dangerous situations such as brake hub cracking, high-temperature tire burst, and brake failure.

At present, the domestic hydraulic retarder market is dominated by foreign enterprises, and the core components rely on imports, resulting in uncontrolled product costs and a lack of reliability. In 2016, China officially implemented the mandatory national standard “Limits for Dimensions, Axle Load, and Mass of Automobiles, Trailers, and Motor Trains” (GB1589-2016). The implementation of this standard has played a significant role in promoting the opening of the hydraulic retarder market, with the most obvious change being the clear regulation of the upper limit of the load capacity of heavy-duty trucks, reducing the effective transportation capacity of logistics vehicles by about 10% to 20%. In the current policy regulations and market environment, the application of hydraulic retarders has become an effective measure to improve transportation efficiency and reduce operating costs.

According to predictions from relevant institutions, the annual sales of medium and heavy-duty trucks in China will remain around 900000 units in the recent three years. It is expected that the penetration rate of the retarder market will have reached around 45% by 2027, and the product market space is broad. At the same time, under the influence of the high popularity of traction vehicles, the demand for hydraulic retarders to match cold chain transportation, green transportation, livestock and poultry, efficient logistics trucks, and small dump trucks will also explode in the next two years.

3. Financing Needs and Purposes

The project is planned to raise 52 million yuan, including 18 million yuan in working capital, 2 million yuan in production materials, and 30 million yuan in fixed assets.

4. Analysis of Technical Achievements and Benefits

4.1 Economic benefits

After the commercialization of the technical achievements of the project, it can generate a market value of approximately 80 million yuan.

4.2 Social benefits

The localized production of the hydraulic retarder, the project product will break the deadlock of high cost imported hydraulic retarders, and can play a significant role in improving vehicle safety, operational efficiency, reducing operating costs, and improving road safety.

5. Contact Method

Contact person: Xu Wan

Tel: 13756652164